Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

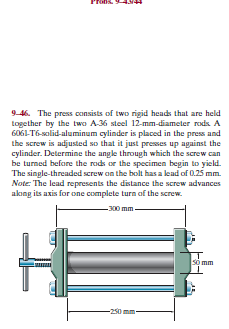

Transcribed Image Text:9-46. The press consists of two rigid heads that are held

together by the two A36 steel 12-mm-diameter rods. A

6061-T6-solid-aluminum cylinder is placed in the press and

the screw is adjusted so that it just presses up against the

cylinder. Determine the angle through which the screw can

be turned before the rods or the specimen begin to yield.

The single-threaded screw on the bolt has a lead of 0.25 mm.

Note: The lead represents the distance the screw advances

akıng its axis for one complete turn of the screw.

-300 mm -

so mm

-250

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 11 images

Knowledge Booster

Similar questions

- The Am1004-T61 magnesium tube is bonded to the A-36 steel rod. A torque of 7.5 kN⋅m is applied to end A. A) Determine the maximum shear stress in magnesium. Express your answer to three significant figures and include the appropriate units. B) Determine the maximum shear stress in steel. Express your answer to three significant figures and include the appropriate units. C) Determine the shear stress on the inside surface of the magnesium tube. Express your answer to three significant figures and include the appropriate units.arrow_forwardThe displayed piece is loaded at 300 N with C in the positive x direction and 200 N in the positive y direction. The diameter of the US bar is 12mm. The part is made of AISI 1040 CD steel. Depending on the error at point A, determine the safety factor by the following methods.(a) maximum shear stress theory.(b) distortion-energy theory.arrow_forwardThe 304-stainless-steel cylinder has an inner diameter of 4 in. and a wall thickness of 0.1 in. If it is subjected to an internal pressure of p = 80 psi, axial load of 500 lb, and a torque of 70 lb · ft, determine if yielding occurs according to the maximum distortion energy theory.arrow_forward

- - once answered correctly will UPVOTE!!arrow_forward8-21. The elastic portion of the stress-strain diagram for an aluminum alloy is shown in the figure. The specimen from which it was obtained has an original diameter of 12.7 mm and a gage length of 50.8 mm. When the applied load on the specimen is 50 kN, the diameter is 12.67494 mm. Determine Poisson's ratio for the material. 8-22. The elastic portion of the stress-strain diagram for an aluminum alloy is shown in the figure. The specimen from which it was obtained has an original diameter of 12.7 mm and a gage length of 50.8 mm. If a load of P = 60 kN is applied to the specimen, determine its new diameter and length. Take v = 0.35. σ (MPa) 490 0.007 Probs. 8-21/22 € (mm/mm)arrow_forwardWhen the two forces are placed on the beam, the diameter of the A-36 steel rod BC decreases from 40 mm to 39.96 mm. (Figure 1) Figure -1 m -1 m P -1 m- B 0.75 m 1 m Part A Determine the magnitude of each force P. Express your answer to three significant figures and include the appropriate units. P = μA Value KN Submit Previous Answers Request Answer Provide Feedback ? X Incorrect; Try Again; 2 attempts remainingarrow_forward

- The rod has a circular cross section. If it is made of an elastic perfectly plastic material, determine the shape factor.arrow_forwardAn axial load is applied to the rectangular cross section bar which is welded at the 57 degree angle shown. If the weld material has a failure normal stress of 160 mPa and a failure shear stress of 90 mPa, determine the required thickness if a factor of safety of 2.3 is required. Also determine the required diameter of the bolts(to the nearest mm) if the plate is face bolted to the supports. The bolt material has a failure shear stress of 175 mPa.arrow_forwardThe acrylic plastic rod is 200 mm long and 15 mm in diameter. If an axial load of 300 N is applied to it, determine the change in its length and the change in its diameter. Ep = 2.70 GPa, np = 0.4.arrow_forward

- The long bolt passes through the 70.4-mm-thick plate. If the force in the bolt shank is 9.5 KN, then the average shear stress (MPa) along the cylindrical area of the plate defined by the section lines a-a is: O a. 0.00 O b. 21.00 O c. 2.39 O d. 4.77 O e. 1.19 18 mm b b 8 mm Time left 0:45:52 a 7 mm YouTube The wood beam has an allowable shear stress of 15 MPa, the maximum shear force V (kN) that can be lind to the cross section is:arrow_forwardDetermine the resulting maximum value of the normal stress. Specify the orientation of the plane on which these maximum values occur. **The answer is tensile stress is 0 ksi at 90 degrees. **The answer is compressive stress is 7 ksi at 0 degrees. Can you explain how that is? This was my thought process: I know that tensile would be zero because the force P is actually going inwards and not outwards. I know that means that there would be a compressive force. I am confused on the angles, how is a tensile force going 90 degress if there technically is no force in the tensile direction. And how is there a compressive force at 90 degrees if there is a stress? thank you!arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY