Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

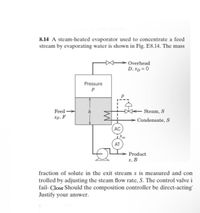

Transcribed Image Text:8.14 A steam-heated evaporator used to concentrate a feed

stream by evaporating water is shown in Fig. E8.14. The mass

Overhead

D, xp = 0

Pressure

Feed

Steam, S

Xp, F

Condensate, S

AC

Xm

AT

Product

x, B

fraction of solute in the exit stream x is measured and con

trolled by adjusting the steam flow rate, S. The control valve i

fail- Close Should the composition controller be direct-acting'

Justify your answer.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- EXPERIMENT: EFFECT OF REGULATING REFLUX RATIO ON TOPPRODUCT COMPOSITION IN DISTILLATION PROCESS OBJECTIVES : i) To perform stage distillation by separating ethanol and water on different tray ii) To study mass fraction for ethanol and water on different tray In summary, the fundamental procedure in distillation was performed clearly. The pure product of ethanol and water were collected on top product valve and bottom product valve respectively. The refractive index for ethanol and water were observed using the refractometer two times to obtain the reading for the first tray and forth tray. QUESTION: PLEASE MAKE AN INTRODUCTION PARAGRAPH BASED ON THIS EXPERIMENT.arrow_forwardWhat is osmosis? What is osmotic pressure? Match the items in the left column to the appropriate blanks in the sentences on the right. higher P=nRT/V solvent II-MRT start solute Psolation Xsolvent Polvent semipermeable stop lower reverse cell Osmosis is defined as the flow of solute concentration to one of pressure is the pressure required to equation from a solution of Reset Help through a solute concentration. membrane. The osmotic the osmotic flow and is given by the followingarrow_forward1. A bioinstrumentation manufacturer mixes four alloy feeds to continuously produce desired alloys to cast scalpels and other surgical equipment. a. Inlet Alloy Feeds 1, 2, 3 and 4 are combined in one mixing unit (see below). The Target Allow I outlet mass flow rate is 1000lbm/hr. F, G, H and K are hypothetical compounds. The weight fractions of components F, G, H and K in the Alloy Feeds and Target Alloy I are given in the table. Calculate the mass flow rates at which the four Alloy Feeds should be supplied to mix to produce the Target Alloy I stream. Alloy Feed 1 Alloy Feed 2- Mixer Alley Feed 3 Target Alloy I Alloy Feed 4 TABLE 3.10 Alloy Feeds and Target Compositions Component weight fractions F. G H K Alloy Feed 1 0.60 0.20 0.20 0 Alloy Feed 2 0.20 0.60 0 0.20 Alloy Feed 3 0.20 0 0.60 0.20 Alloy Feed 4 0 Target Alloy I 0.25 0.20 0.20 0.60 0.25 0.25 0.25 b. For a different application, Alloy Feed 1 and 2 are combined in a mixing tank labeled mixer 1 (see figure). The weight…arrow_forward

- You are working on determining the Oxygen Transfer Rate (OTR) and Oxygen Uptake Rate (OUR) in a bioreactor. You perform two set of experiments in a 3L bioreactor. During the first set of experiments, you fill the bioreactor with water only, you remove all the dissolved oxygen and start sparging it with air at the specified agitation speeds and air flowrate. Which of the following methods could be used to estimate the volumetric oxygen transfer coefficient (kLa)? C*: saturation concentration of dissolved Oxygen CL: concentration of dissolved Oxygen at any given time Question options: kLa is the slope of a ln(C* ) versus time plot kLa is the slope of a CL versus time plot -kLa is the slope of a ln(C* - CL) versus time plot kLa is the slope of a ln(C* - CL) versus time plotarrow_forwardQuestion 1 Make a short report on “History of rocket propulsion”. Question 2 Define the following (with the help of hand sketches) for solid rocket engine: a. Delay time b. Rise time c. Action time d. Burning time e. Progressive burning f. Regressive burning g. Neutral burning Question 3 Draw the different types of grain configurations (by hand) and write their type of burning. Question 4 Make a table of various propellants used in rocket propulsion. This may include propellant name, fuel and/or oxidizer, chemical formula (if available), physical state (solid/liquid) etc. Question 5 Draw the neat sketches (by hand) of solid and liquid rocket systems separately. Label various components of the same. Question 6 Make a short report on vehicles used for space missions recently.arrow_forwardPlease help with homework problem.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The