Advanced Engineering Mathematics

10th Edition

ISBN: 9780470458365

Author: Erwin Kreyszig

Publisher: Wiley, John & Sons, Incorporated

expand_more

expand_more

format_list_bulleted

Question

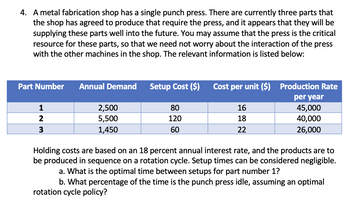

Transcribed Image Text:4. A metal fabrication shop has a single punch press. There are currently three parts that

the shop has agreed to produce that require the press, and it appears that they will be

supplying these parts well into the future. You may assume that the press is the critical

resource for these parts, so that we need not worry about the interaction of the press

with the other machines in the shop. The relevant information is listed below:

Part Number

Annual Demand

Setup Cost ($)

Cost per unit ($) Production Rate

per year

1

2,500

80

16

45,000

2

3

5,500

120

18

40,000

1,450

60

22

26,000

Holding costs are based on an 18 percent annual interest rate, and the products are to

be produced in sequence on a rotation cycle. Setup times can be considered negligible.

a. What is the optimal time between setups for part number 1?

b. What percentage of the time is the punch press idle, assuming an optimal

rotation cycle policy?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 11 images

Knowledge Booster

Similar questions

- Below is a decision table for Gregor's Tennis School. Director Gregor Anderson is considering expanding his school to accommodate the potential increased interest in youth tennis lessons, camps and teams. The decision table below describes his situation. Alternatives Add a new building Extend hours for existing building Do Nothing Answer Decision Table High Demand 25,000 10,000 0 Step 1 of 3: What is the estimated payoff for adding a new building during high demand? State of Nature Moderate Demand 5,000 3,750 0 Low Demand -50,000 -6,000- 0 Keypad Keyboard Shortcuts Tablesarrow_forward5. Next Monday, Concrete Co need to supply concrete to four different building sites. They prefer to use plants 1 and 2 for the production and delivery of the concrete, because they are quite close to the sites, but find it necessary to use plant 3 to satisfy the rest of the demand. The table below shows supply and demand amounts in tonnes, and cost coefficients in $ per tonne. Cij Site 1 70 40 130 75 Plant 1 Plant 2 Plant 3 Demand Site 2 40 50 210 23 Site 3 20 30 80 19 Site 4 50 60 90 25 Supply 80 55 7 Concrete Co wish to minimise their total cost. Treat this as a primal LP problem. (a) Show that Concrete Co have balanced their transportation problem. (b) Use the Least Cost Method to find a basic feasible solution to this primal problem. Verify that you have the correct number of basic variables. [Hint: You should look at 13 first. Then 12 and 21 are both contenders, but it does not matter what order you choose them in.] (c) Use complementary slackness conditions to find a dual…arrow_forwardneed comprehensive and correct answers.This question is about optimization.arrow_forward

- Cox Electric makes electronic components and has estimated the following for a new design of one of its products: Fixed Cost = $3,000 Material cost per unit = $0.15 Labor cost per unit = $0.10 Revenue per unit = $0.65 Production Volume = 12,000 Per-unit material and labor cost together make up the variable cost per unit. Assuming that Cox Electric sells all it produces, build a spreadsheet model that calculates the profit by subtracting the fixed cost and total variable cost from total revenue, and answer the following questions. (a) Construct a one-way data table with production volume as the column input and profit as the output. Breakeven occurs when profit goes from a negative to a positive value; that is, breakeven is when total revenue = total cost, yielding a profit of zero. Vary production volume from 5,000 to 50,000 in increments of 5,000. In which interval of production volume does breakeven occur? to unitsarrow_forwardA company is producing 3 products A ,B and C. BOM of each product is given in the table below. Material Unit Product A Product B Product C Steel Ton 4 Aluminum KG 50 40 60 Wood CFT 10 10 Glass SFT 30 30 Rubber Sealer RFT 100 120 Screws Рack 5 6 4 Nut Bolt Dozen 2 Calculate the material requirements for 6 months production for all the products if monthly demand for A=1000, B=1200 and C=1500 unitsarrow_forwardplease helparrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education

Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY

Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,

Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,

Advanced Engineering Mathematics

Advanced Math

ISBN:9780470458365

Author:Erwin Kreyszig

Publisher:Wiley, John & Sons, Incorporated

Numerical Methods for Engineers

Advanced Math

ISBN:9780073397924

Author:Steven C. Chapra Dr., Raymond P. Canale

Publisher:McGraw-Hill Education

Introductory Mathematics for Engineering Applicat...

Advanced Math

ISBN:9781118141809

Author:Nathan Klingbeil

Publisher:WILEY

Mathematics For Machine Technology

Advanced Math

ISBN:9781337798310

Author:Peterson, John.

Publisher:Cengage Learning,