Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Ch12 #32-Please assist me with answering a, b and c. Please provide step by step instructions as to how you arrive at each answer. Please do not skip steps as the process is important.

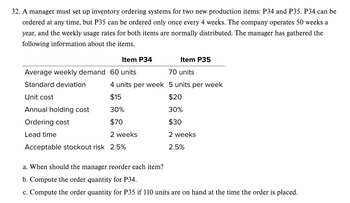

Transcribed Image Text:32. A manager must set up inventory ordering systems for two new production items: P34 and P35. P34 can be

ordered at any time, but P35 can be ordered only once every 4 weeks. The company operates 50 weeks a

year, and the weekly usage rates for both items are normally distributed. The manager has gathered the

following information about the items.

Item P34

Average weekly demand 60 units

Standard deviation

Unit cost

Annual holding cost

Ordering cost

Lead time

70 units

4 units per week 5 units per week

$15

$20

30%

30%

$70

$30

2 weeks

2 weeks

2.5%

Item P35

Acceptable stockout risk 2.5%

a. When should the manager reorder each item?

b. Compute the order quantity for P34.

c. Compute the order quantity for P35 if 110 units are on hand at the time the order is placed.

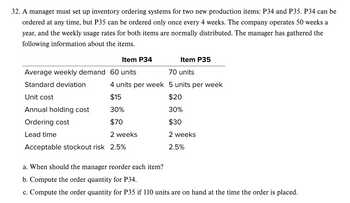

Transcribed Image Text:32. A manager must set up inventory ordering systems for two new production items: P34 and P35. P34 can be

ordered at any time, but P35 can be ordered only once every 4 weeks. The company operates 50 weeks a

year, and the weekly usage rates for both items are normally distributed. The manager has gathered the

following information about the items.

Item P34

Average weekly demand 60 units

Standard deviation

Unit cost

Annual holding cost

Ordering cost

Lead time

70 units

4 units per week 5 units per week

$15

$20

30%

30%

$70

$30

2 weeks

2 weeks

2.5%

Item P35

Acceptable stockout risk 2.5%

a. When should the manager reorder each item?

b. Compute the order quantity for P34.

c. Compute the order quantity for P35 if 110 units are on hand at the time the order is placed.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- Very simple answer needed, no word limitations. Question. You are the marketing executive for a large soft drink company. Your company is in the process of singing a superstar female singer to promote your product. Discuss the reference group related factors that you would have to consider when signing the celebrityarrow_forwardNo chatgpt used i will give 5 upvotes typing please i need both answers a and barrow_forwardSBL Corporation is preparing to expand into B2B e-business. It is least likely to need which of the following database tables as part of its network? Group of answer choices A. Customer B. Employee C. Business D. Orderarrow_forward

- What are the shortcomings of Non-Return-to-Zero (NRZ) encoding? The question at hand is of significant importance, thus prompting the inquiry of how it can be effectively resolved?arrow_forwardbased on the information solved please answer part d) & e)arrow_forwardWhich of the following is FALSE regarding decision making? O a. It is an ongoing process in the organization O b. It is a one-time work in the organization O c. It involves the analysis of possible alternatives O d. It involves collection of informationarrow_forward

- Please do not give solution in image format thanku Evaluate the effectiveness of the strategies employed by ABC Corporation to overcome resistance to change during the transition to the new management information system. How successful were these strategies in fostering employee acceptance and adoption of the new system?arrow_forwardWhich sentence could be included in a response to a complaint in order to reaffirm the customer's value to the company? Your business and patience are greatly appreciated. Thank you for making me aware of the situation. We apologize for any inconvenience. I have met with the employee you mentioned to discuss the issue.arrow_forwardBased on the Service System Design Matrix, a higher degree of customer contact during the service: Group of answer choices A. Causes higher production efficiency. B. Leads to more sales opportunity. C. Generally requires more interpersonal skills. D. Both B and C are correct E. All of the above are correctarrow_forward

- The executive team at DataX Space is working hard to make the organization a safer place for employees to work. All except which of the following actions would help improve safety? Create and implement a policy regarding emergency situations Appoint a coordinator to oversee the development and implementation of the plan Create an advisory committee to oversee safety concerns Appoint a safety specialist to enforce all safety practicesarrow_forwardWhat decision-making format would best be used when giving a straight final warning to an employeearrow_forwardWhich of the following is true of skip questions? Skip questions are not a problem with online surveys since the computer controls the sequence of answering questions. In order to speed through the data collection process, an interviewer may ask the respondent a few skip questions. If a respondent on a survey fails to follow instructions for skip questions, the interviewer may inject a tone of negativity into the interviewing process. If an interviewer (or respondent on a self-administered survey) fails to follow instructions for skip questions, the respondent can skip those questions. If an interviewer (or respondent on a self-administered survey) fails to follow instructions for skip questions, he or she cannot recontact respondents and verify their responsesarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.