Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

Problem statement is asking for volumetric flowrate*

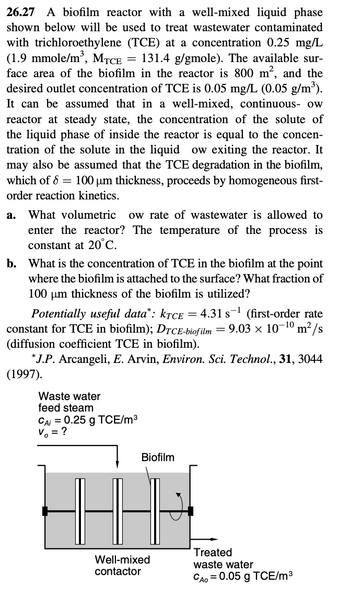

Transcribed Image Text:26.27 A biofilm reactor with a well-mixed liquid phase

shown below will be used to treat wastewater contaminated

with trichloroethylene (TCE) at a concentration 0.25 mg/L

(1.9 mmole/m³, MTCE = 131.4 g/gmole). The available sur-

face area of the biofilm in the reactor is 800 m², and the

desired outlet concentration of TCE is 0.05 mg/L (0.05 g/m³).

It can be assumed that in a well-mixed, continuous- ow

reactor at steady state, the concentration of the solute of

the liquid phase of inside the reactor is equal to the concen-

tration of the solute in the liquid ow exiting the reactor. It

may also be assumed that the TCE degradation in the biofilm,

which of 8 = 100 µm thickness, proceeds by homogeneous first-

order reaction kinetics.

a. What volumetric ow rate of wastewater is allowed to

enter the reactor? The temperature of the process is

constant at 20°C.

b. What is the concentration of TCE in the biofilm at the point

where the biofilm is attached to the surface? What fraction of

100 μm thickness of the biofilm is utilized?

Potentially useful data*: KTCE = 4.31 s ¹ (first-order rate

constant for TCE in biofilm); DTCE-biofilm = 9.03 × 10-¹0 m²/s

(diffusion coefficient TCE in biofilm).

*J.P. Arcangeli, E. Arvin, Environ. Sci. Technol., 31, 3044

(1997).

Waste water

feed steam

CAi = 0.25 g TCE/m³

V = ?

Biofilm

4-8

Well-mixed

contactor

Treated

waste water

CAO = 0.05 g TCE/m³

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- Liquid is flowing through a circular pipe in a laminar phase. Now, the fluid through the pipe is replace with a more viscous fluid and passed through the pipe again with the same velocity. What will be the nature of flow of the fluid? Eddies will star to form B The flow will become turbulent Insufficient data to define The fluid will remain laminar The flow will start to be transitionalarrow_forward1. Water (p= 1000 kg m-³ and μ = 0.0011 kg m-¹ s-1) flows at 5 m s-1 over a 0.3 m long flat plat. Determine if the flow in the boundary layer is laminar over the entire length of the plat or it becomes turbulent at a downstream location. If latter is the case, determine the location of transition from laminar to turbulent. [Ans. BL flow is Laminar & turbulent, x = 0.11 m]arrow_forwardSeveral different classifications of fluid flows were outlined - match each of the class pairs listed. Viscous A. Inviscid Extrernal B. Turbulent Incompressible C. Internal Laminar D. Compressiblearrow_forward

- Q4- Water flows at a velocity of 1 m/s over a plane surface 0.6 m wide and 1 m long. Calculate the total drag force acting on the surface if the transition from streamline to turbulent flow in the boundary layer occurs when the Reynolds group Re, = 105 and Taking == 1 mN s/m² = 10-³ Ns/m².arrow_forward6.2. Air is flowing through a horizontal tube with 1.00-in inside diameter. What is the maximum average velocity at which laminar flow will be of the stable flow pattern? What is the pressure drop per unit length at this velocity?arrow_forwardlarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The