Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

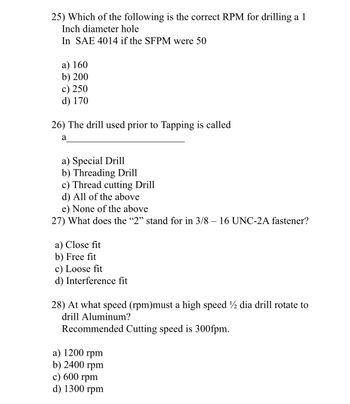

Transcribed Image Text:25) Which of the following is the correct RPM for drilling a 1

Inch diameter hole

In SAE 4014 if the SFPM were 50

a) 160

b) 200

c) 250

d) 170

26) The drill used prior to Tapping is called

a

a) Special Drill

b) Threading Drill

c) Thread cutting Drill

d) All of the above

e) None of the above

27) What does the "2" stand for in 3/8 – 16 UNC-2A fastener?

a) Close fit

b) Free fit

c) Loose fit

d) Interference fit

28) At what speed (rpm)must a high speed ½ dia drill rotate to

drill Aluminum?

Recommended Cutting speed is 300fpm.

a) 1200 rpm

b) 2400 rpm

c) 600 rpm

d) 1300 rpm

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- 42) What are the names given to the three Taps used for Tapping Holes? a) Taper, Plug,Bottoming b) Taper, Fine, Course c) Fine,Course, Bottoming d) Top,Bottoming, Side 43) What does 16 represent for the Notation of 3/8-16UNC- 2A. a) Outside Diameter of a screw b) 16 Threads per Inch c) Fine Thread of the Screw d) Thread Tolerance 44) What does 3/8 represent for the Notation of 3/8-16 UNC- 2A a) Outside diameter of the Screw b) 16 Threads per Inch c) Fine Thread of the screw d) Thread Tolerance 45) Cutting Speed is ? a) The Peripheral distance travelled by The cutter b) The RPM of the Chuck c) The speed of the metal chips being cut d) The Feed Ratearrow_forward3. Soru If the shaft is always smaller than the hole, general fit name is Fill in the blank with correct option. A) Press fit B) Interference fit C) Transition fit D) Clearance fitarrow_forward10-12 Answer it correctly and this is Asap I will rate helpful if fast and perfectarrow_forward

- 17) The Feed Rate on a Conventional lathe is measured in a) Feet per minute b) Inches per Revolution c) Inches per minute d) Inches per tooth 18) From a feed and Speed chart we find that a single point lathe tool is given a cutting speed of 100 FPM and a feed per revolution 0.007.If the diameter of the Workpiece is 1.25 inches What is the correct RPM and Feed rate used on the Lathe? a) 320 RPM and 0.007 IPR b) 100 RPM and 7 IPM c) 3200RPM and 0.007 IPR d) 125 RPM and 0.007 IPR 19) To Fix a small bump left on the Face of a workpiece in a lathe a) Use a file b) Ignore it c) Adjust the tool on centre again 20) The best tool to use to Chamfer a hole is a a) Chamfer file b) Counterbore c) Countersink d) Reamer 01arrow_forward16-18 Answer it correctly and this is Asap I will rate helpful if fast and perfectarrow_forward8-In lathe, the carriage and tail stock are guided on... a) Same guideways. b) Different guideways. c) Any of the above. d) Not guided on guidewaysarrow_forward

- I need it in 15 minutesarrow_forward22-25.arrow_forwardA. MULTIPLE CHOICE : Select the best answer. Write the letter of the correct answer on the blank provided before each number. 1) The process of aligning the work axis along the axis of the lathe spindle is called a) facing b) straight turning c) centering d) drilling 2) The tool that is provided with a scriber and is used for centering a workpiece held in a chuck a) wiggler b) center drill c) dial indicator d) surface gage a chuck is 3) The instrument that is commonly used for accurate centering of a work piece held in a) wiggler b) dial indicator c) Vernier protractor d) surface gage 4) A method of centering a workpiece without any tool or instrument is a) wiggler b) dial indicator c) chalk d) surface gage 5) The approximate center of the work piece can be obtained by using as guide, is the chuck a) jaws b) concentric ring c) slots d) threads 6) A hexagon is assumed to be centered if the scriber point of the surface gage is touching all its a) flats b) corners c) side d) ends 7) If…arrow_forward

- A H7/h6 hole/shaft combination denotes a) running fit c) press fit b) push fit d) locational clearance fitarrow_forward33) What reason would a Tap break during Tapping: a) Moving Tap from 12:00 am to 3:00 then back to 12:00 am b) Moving Tap from 12:00 am to 11:00 c) Using a Taper Tap with Oil d) None of the above 34) Why is the Reaming operation performed? a) To clean a drilled hole for Dowel Pins b) To make a drilled hole larger c) Used instead of a Tap Drill d) Used for making fine Threads 35) The difference between a UNC thread and UNF thread is a) UNC Thread has less threads per Inch b) UNF Thread has less threads per Inch c) UNC has less tensile strength d) UNC has more thread contact 36) The hole to be Tapped must be: a) The same diameter as the desired thread b) A few thousandth larger than the desired thread c) 0.003 to 0.004 smaller than the desired thread d) All of the above e) None of the abovearrow_forwardThe tool life decreases from 0.8 min to 0.2 min due to the increase in cutting speed from 60 m/min to 120 m/min in a turning operation.Compute is the value of the cutting speed at 0.4 min.a-)Determine the spindle speed in rpm.b-)Find the required power for the unit force.c-)The friction between tool and workpiece varies 0.25-0.35 during the process.d-)Calculate the rate of maximum force to minimum force.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY