Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

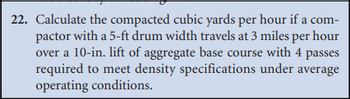

Transcribed Image Text:22. Calculate the compacted cubic yards per hour if a com-

pactor with a 5-ft drum width travels at 3 miles per hour

over a 10-in. lift of aggregate base course with 4 passes

required to meet density specifications under average

operating conditions.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Base course aggregate has a target dry density of 1917 Kg/m3 in place. It will be laid down and compacted in a rectangular street repair area of 600m * 15m * 9.15m. The aggregate in the stockpile contains 3.1% moisture. If the required compaction is 95% of the target, how many tons of aggregate will be needed?arrow_forwardHANDWRITTEN ONLY... needed urgently do it as fast as possible...arrow_forwardHelp, Help new solution pleasearrow_forward

- (c) Asphalt concrete mixture of AC 14 will be used to construct the wearing course layer. The coarse aggregate, fine aggregate and filler are used as materials to produce the asphalt concrete mixture. The aggregate gradation will be blended to fulfill the gradation limit according to JKR standard specification as shown in Table Q1(c)(i). Based on this statement, conclude the result of sieve analysis test of blended aggregate as shown in Table Q1(c)(ii). I Table Q1(c)(i): Gradation specification for AC 14 mixture BS Sieve Size (mm) Percentage passing by weight 28.0 20.0 14.0 10.0 5.0 3.35 1.18 0.425 0.150 0.075 100 90-100 76-86 50-62 40-54 18-34 12-24 6-14 4-8 I Act Go toarrow_forwardAccording to available data shown in Tables 2, calculate the following: a. Compute the desired Gradation (blend ratios of each fraction) using trial and error method. b. Find Total Gsb, Gse „Pba and Pbe according to asphalt Gb 1.015, Gmm-2.658 and Pb=4.5%. Tabłe 2: Aggregate Gradation Analysis Mid Specifications Limits Sieve Blend A Size (in) Gradation Limits 3/4" 100 100 100 100 1/2" 90 100 100 80-100 3/8" 59 100 100 70-90 No.4 16 96 100 50-70 No.8 3.2 82 100 35-50 No.30. 1.1 51 100 18-29 No.50 36 98 13-23 No.100 21 93 8-16 No.200 9.2 82 4-10 2.785 2.687 2.734 Note: Gse 100 x Gsb Gb GsbxGse Pmm Pb Pmm Gse Gmm Pba %3D %3D Ртт Pb Ps Pb Gmm Gb Gse Gb Pba xPs 100 Pbe = Pbarrow_forwardSITUATION 2: The ground floor of a residential house has an area of 200 square meters. The plan specifies 4 inches thick concrete floor on fill using Class C concrete mix. Determine the following: Use AREA METHOD. MIXTURE CLASS SAND GRAVEL Thick 50 kg. Cement Per Bag B 40 kg. Cement Per Bag in ness cm. cu. m. 5.0 450 375 30 350 300 .250 .0250 .050 7.5 .675 .563 45 525 450 375 .0375 .075 10.0 .900 .750 60 .700 600 .500 .0500 .100 12.5 1.125 .938 .75 875 750 .625 .0630 .125 15.0 1.350 1.125 90 1.050 .900 .750 .0750 .150 17.5 1.575 1.313 1.05 1.225 1.050 .875 .0880 .175 20.0 1.800 1.500 1.20 1.400 1.200 1.000. 1000 200 22.5 2.030 1.688 1.35 1.575 1.350 1.125 1125 .225 25.0 2.250 1.875 1.50 1250. 250 1.750 1.500 1.250 27.5 2.475 2.063 1.65 1.925 1.650 1.375 .1380 275 36.0 2.700 2.250 1.80 2.100 1.800 1.500 .1500 300 Quantity of cement in bags (50kg). Your answer Sand in cubic meters Your answer Gravel in cubic meters Your answerarrow_forward

- C. Using the sieve results of a batch of sand and gravel shown in the table below,calculate the fineness modulus for the Sand and Gravel blend if the P sand is 45 % and P Gravel is 55 %. answer the below questions: Amount Amount Sieve No. Retainded (g) Retainded (g) (Sand) (Gravel) 1.5" 22.1 1" 34 0.75" 25.2 161.3 0.5" 52 134 3/8" 109.2 114.4 No. 4 97 19.1 No. 8 46.4 16.1 No. 16 21.2arrow_forwardPlease provide a well detailed solution. Thank youarrow_forwardAfter 2 years of traffic, cores were recovered from the roadway which has severe rutting and bleeding. The bulk specific gravity and the maximum theoretical specific gravity were measured on these cores and are as follows:a. Bulk specific gravity = 2.487b. Maximum theoretical specific gravity = 2.56 1 c. Calculate the air voidsd. If the design air void content was 4%, explain what effect the calculated air voids had on the rutting and bleeding noted.arrow_forward

- The specific gravities and weight proportions for aggregate bitumen are as under for the préparation of Marshall Mix design. The volume and weight of one marshall specimen was found to be 475 cc and 1100 gm. Assuming absorption of bitumen in aggregate is zero. Find V Vp₁ VMA and VFB. Item Weight Specific Gravity Aggregate-1 Aggregate-2 Aggregate-3 Aggregate-4 Bitumen 825 1200 325 150 100 2.63 2.51 2.46 2.43 1.05arrow_forwardUsing the following data for an unreinforced PCC Pavement slab: ▪ Design Strength f`c = 4000 psi ▪ Slab thickness = 12” ▪ Standard deviation of f`c obtained from 20 samples = 200 psi ▪ Ignore any exposure requirement ▪ Use air entrained concrete ▪ Fineness Modulus of Fine Aggregates = 2.60 ▪ Maximum aggregate Size = 2” and nominal maximum aggregate size 1 ½ “ ▪ Bulk oven-dry specific gravity of Coarse Aggregate = 2.60 ▪ Oven-dry rodded density of coarse aggregate = 125 pcf Find the following: a) Required compressive strength b) Water-Cement Ratio c) Coarse aggregate amount (lb/yd3 ) d) If the w/c ratio is 10% reduced, will the quantity of coarse aggregate increase, decrease or remain the same? Explain your answer.arrow_forwardOAt a ready-mix concrete plant 65 tons of cement, 190 tons of fine aggregate, 250 tons of coarse aggregate and 50 tons of water are available before the end of the day. The plant manager knows that the next day (s)he has to deliver a total of 200 m³ of concrete. In the laboratory, the moisture content of sand and gravel was determined as 1.2 % and 0.2%, respectively and the absorption capacities are 0.8 % for both materials. SSD bulk specific gravities are 2.60 and 2.70 for sand and gravel, respectively. Specific gravity of cement is 3.15. Mix design based on field weight of aggregates: Ingredient Weight (kg/m2-concrete) Field Cement 350 Fine aggregate Coarse aggregate 750 950 Water 195 Calculate the maximum volume of concrete that can be produced with the available materials at the field. What should the plant manager do? [18 pts] 7) The grading of three aggregates is given below. MONSTERarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning