Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

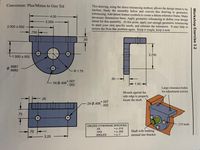

This drawing using the direct tolerancing method, allows the design intent to be unclear. Study the assembly below and convert this drawing to geometric tolerancing. Add datum feature symbols to create a datum reference frame. Make necessary dimensions basic. Apply geometric tolerancing to define your design intent for this assembly. At this point, apply just enough geometric tolderancing to meet your own specific needs, and estimate the tolerances.

Please help!! Also please refer to the attached image.

Transcribed Image Text:Conversion: Plus/Minus to Geo Tol

This drawing, using the direct tolerancing method, allows the design intent to be

unclear. Study the assembly below and convert this drawing to geometric

tolerancing. Add datum feature symbols to create a datum reference frame. Make

necessary dimensions basic. Apply geometric tolerancing to define your design

intent for this assembly. At this point, apply just enough geometric tolerancing

to meet your own specific needs, and estimate the tolerances. It may help to

review the Hole Bar problem again. Keep it simple, keep it neat.

4.00

3.250

2.000 ±.002

.750

.50

2.250

1.000 +.002

.9987

.9982

R 1.75

.50 -

+.007

3XФ.406

1.50 +

-.002

Large clearance holes

for adjustment screws

Mounts against the

side edge to properly

.25

locate the shaft.

+.007

2X Ф 406002

.75

.375 bolts

UNLESS OTHERWISE SPECIFIED:

= ± .010

.XX

.75

.XXX

= ±.005

Shaft with bushing

ANGLES

= ± 1°

pressed into bracket

-3.25

Workshop Exercise 3.2

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Similar questions

- Hello Sir,Good Evening. I have a question in my homework realated geometry tolerance lesson. The following below is my question. Please advice thank you. "What is the difference between position tolerance and orientation tolerance?"arrow_forwardThe entire top surface on the part below must be flat within 0.5 but each 25x25 patch must be flat within 0.1. Apply the necessary geometric controls to achieve this result. Please refer to the attached image.arrow_forwardhow do I dimension the object shown below assume grid spacing is 0.2arrow_forward

- Hello pls sketch left side, front and top viewsarrow_forwardHello Sir.Good Night. I have a question in my homework related geometry tolerance lesson. The following below is my question. Please advice. Thank youarrow_forwardI need a clear answer by hand, not by keyboard and fast answer within 20 minutes. Thank you | dybalaarrow_forward

- Can someone please help me to solve this graphically on CAD as well as analytically. Show all work thank you!arrow_forwardPlease help. I need help with all 4 questions. Apply geometric tolerancing to part according to the instructions below. This exercise will provide you with experience in correctly applying and interpreting geometric tolerancing symbology. If you have trouble applying the symbols, page through this unit looking for similar examples. The Hole Bar in this unit is a good reference. Draw symbols and feature control frames clearly and neatly. 1. Establish all necessary basic dimensions. 2. Position the .250 hole within a diameter of .005 RFS relative to datum features A,B,C. 3. Position the three holes within a diamter of .012 at MMC relative to datum features A,B,C. 4. In the front view, identify the upper right corner as point "Y" and the lower left corner as point "X". Apply a profile tolerance of .020 between points X and Y relative to datum features A,B,C. Please refer to the attached image.arrow_forwardUsing AutoCAD, draw the following image using object snap modes step by steparrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY