Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

thumb_up100%

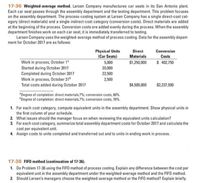

Transcribed Image Text:17-36 Weighted-average method. Larsen Company manufactures car seats in its San Antonio plant.

Each car seat passes through the assembly department and the testing department. This problem focuses

on the assembly department. The process-costing system at Larsen Company has a single direct-cost cat-

egory (direct materials) and a single indirect-cost category (conversion costs). Direct materials are added

at the beginning of the process. Conversion costs are added evenly during the process. When the assembly

department finishes work on each car seat, it is immediately transferred to testing.

Larsen Company uses the weighted-average method of process costing. Data for the assembly depart-

ment for October 2017 are as follows:

Physical Units

(Car Seats)

Direct

Conversion

Materials

$1,250,000

Costs

$ 402,750

Work in process, October 1

Started during October 2017

Completed during October 2017

Work in process, October 31b

Total costs added during October 2017

5,000

20,000

22,500

2,500

$4,500,000

$2,337,500

"Degree of completion: direct materials,?%; conversion costs, 60%.

Degree of completion: direct materials,?%; conversion costs, 70%.

1. For each cost category, compute equivalent units in the assembly department. Show physical units in

the first column of your schedule.

2. What issues should the manager focus on when reviewing the equivalent units calculation?

3. For each cost category, summarize total assembly department costs for October 2017 and calculate the

cost per equivalent unit.

4. Assign costs to units completed and transferred out and to units in ending work in process.

17-38 FIFO method (continuation of 17-36).

1. Do Problem 17-36 using the FIFO method of process costing. Explain any difference between the cost per

equivalent unit in the assembly department under the weighted-average method and the FIFO method.

2. Should Larsen's managers choose the weighted-average method or the FIFO method? Explain briefly.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Some IT Systems indicate where the material should be placed in marked spaces on a table or floors. Subject to empty space, supplying operations are reported to generate more. What are the names of these spaces?arrow_forwardBoth lead time and safety stock are used in practice and can be used simultaneously. Select one: O True O Falsearrow_forwardIs there a hierarchy of importance for non-functional requirements? Explain why.《...》arrow_forward

- As the MTTR drops to zero, what does it signify for availability? Can this be characterized as a realistic situation?arrow_forwardBreak-even volume is the number of unit sales required for total revenue to cover total cost. Select one: O True O Falsearrow_forwardA make-to-order strategy produces products to customer specifications in large volumes. True Falsearrow_forward

- The following table provides a random sample of the unit values and annual demands of eight SKUs. SKU Code Unit Value Demand (units) A104 $0.02 D205 $2.60 X104 $4.80 U404 $2.50 L205 $0.36 S104 $0.84 X205 $4.35 L104 $0.23 4,500 30 25 2,500 1,040 380 70 250 Southern Markets Inc. is considering the use of ABC analysis to focus on the most critical SKUs in its inventory. a. Based on the percentage of dollar usage, which class should L205 belong to? Class b. Based on the percentage of dollar usage, which class should L104 belong to? Classarrow_forwardWhat happens to availability when the MTTR (time between failures) approaches zero? Can we provide an accurate description of this situation?arrow_forwardPlease do not give solution in image format thankuarrow_forward

- Two years ago Top-Slice Company moved from just making golf balls to also producing oversized drivers. Top-Slice makes three different models: the Bomber, the Hook King, and the Sir Slice-A-Lot. As the names suggest, the last two clubs help correct for golfers who either hook or slice the ball when driving. While Top-Slice is pleased with the growing sales for all three models (see the following tables), the numbers present Jacob Lee, the production manager, with a dilemma. Jacob knows that the current manufacturing work cell is capable of producing only 2,700 drivers a month, and total sales seem to be rapidly approaching that number. Jacob’s staff has told him it will take at least three months to plan for and implement an expanded work cell. Develop a forecast for Top-Slice Company. Which forecast model works best? Why? Suppose information is received that makes clear that sales are expected to go down. How would this affect the choice of a forecasting model?arrow_forwardS&OP is typically a(n) ________ firm process. Group of answer choices External Internal None of these answersarrow_forwardThe Northridge Company tends to keep the inventory low. At the same time, it is important to respond to demand quickly, since a customer who wants a product K is very likely to get one from a competitor if Northridge Company doesn’t have one available immediately. Northridge Company’s current policy to produce the product K is to produce 100 per week, which is the average demand. Even this is a problem, as the production manager has pointed out, since the equipment is also used for other products and the lot size of 300 would be much more efficient. He said he is currently set up the production for product K for the next week and states that he has capacity available to produce 300 at a time next week. The following lists the forecasts and actual customer orders for the next 12 weeks. Week 1 2 3 4 5 6 7 8 9 10 11 12 Forecast 90 120 110 80 85 95 100 110 90 90 100 110 Customer Orders 105 97 93 72 98 72 53 21…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.