Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

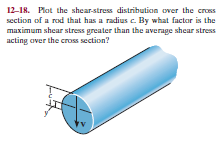

Transcribed Image Text:12-18. Plot the shear-stress distribution over the cross

section of a rod that has a radius c. By what factor is the

maximum shear stress greater than the average shear stress

acting over the cross section?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- The solid steel shaft has a diameter of 35 mm. Determine the absolute maximum shear stress in the shaft.arrow_forwardThe applied shear force is V = 24 kip. 3 in. 1 in. 3 in. 1 in. 1 in. Part A Determine the maximum shear stress in the member. Express your answer to three significant figures and include appropriate units. HẢ ? Value Units Tmax =arrow_forwardDetermine the principal stresses in the cantilevered beam at points A and B.arrow_forward

- 7.2 need help Provide free body diagram thank you.arrow_forwardThe rectangular plate is subjected to the deformation shown by the dashed line. Assume a = 550 mm, Ax = 2.2 mm, and Ay = 1.4 mm. Determine the shear strains Yxy and Yxy at point A. Ay Ay Answers: Vxy= | i Ax Yxy= i eTextbook and Media Save for Later X urad urad Attempts: 0 of 5 used Submit Answerarrow_forwardMechanics of materials IIarrow_forward

- 8-27. The lap joint is connected together using a 30 mm diameter bolt. If the bolt is made from a material having a shear stress-strain diagram that is approximated as shown, determine the permanent shear strain in the shear plane of the bolt when the applied force P- 680 kN is removed. 7 (MPa) 525 350 (rad) 0.005 0.05arrow_forwardThe d = 17-mm-diameter solid rod passes through a D = 22-mm-diameter hole in the support plate. When a load P is applied to the rod, the rod head rests on the support plate. The support plate has a thickness of b = 10 mm. The rod head has a diameter of a = 34 mm, and the head has a thickness of t = 8 mm. The shear stress in the rod head cannot exceed 145 MPa, the punching shear stress in the support plate cannot exceed 100 MPa, and the bearing stress between the rod head and the support plate cannot exceed 145 MPa. Determine the maximum value of Pmax that can be supported by the structure.arrow_forwardThe beam has a square cross section and is made of wood having an allowable shear stress of Tallow= 1.4 ksi. If it is subjected to a shear of V= 1.5 kip, determine the smallest dimension a of its sides. Sketch the shear stress distribution acting across the beam's cross section. Hint: Construct the stress distribution in 2D similar to in-class examples, rather than isometrically similar to the textbook examples for clarity. V = 1.5 kiparrow_forward

- Determine the normal strains at the point associated with the x and y axes. Determine the shear strain at the point associated with the x and y axes. Determine the normal stresses at the point associated with the x and y axes. Determine the shear stress at the point. Determine the normal stress that acts along an axis rotated at θ= 45° counterclockwise from the positive x-axis.arrow_forwardThe long bolt passes through the 70.4-mm-thick plate. If the force in the bolt shank is 9.5 KN, then the average shear stress (MPa) along the cylindrical area of the plate defined by the section lines a-a is: O a. 0.00 O b. 21.00 O c. 2.39 O d. 4.77 O e. 1.19 18 mm b b 8 mm Time left 0:45:52 a 7 mm YouTube The wood beam has an allowable shear stress of 15 MPa, the maximum shear force V (kN) that can be lind to the cross section is:arrow_forwardA lever is attached to a shaft with a square shear key as shown. If the force applied to the lever is P = 395 N, determine the shear force applied to the shear key. 42 mm. ↓ Shear key O 10.90 KN O 18.31 KN O 9.70 KN O 14.25 KN O 13.17 kN 700 mm C Shear key detailarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY