Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

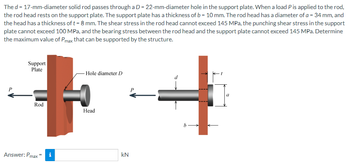

The d = 17-mm-diameter solid rod passes through a D = 22-mm-diameter hole in the support plate. When a load P is applied to the rod, the rod head rests on the support plate. The support plate has a thickness of b = 10 mm. The rod head has a diameter of a = 34 mm, and the head has a thickness of t = 8 mm. The shear stress in the rod head cannot exceed 145 MPa, the punching shear stress in the support plate cannot exceed 100 MPa, and the bearing stress between the rod head and the support plate cannot exceed 145 MPa. Determine the maximum value of Pmax that can be supported by the structure.

Transcribed Image Text:The d = 17-mm-diameter solid rod passes through a D = 22-mm-diameter hole in the support plate. When a load P is applied to the rod,

the rod head rests on the support plate. The support plate has a thickness of b = 10 mm. The rod head has a diameter of a = 34 mm, and

the head has a thickness of t = 8 mm. The shear stress in the rod head cannot exceed 145 MPa, the punching shear stress in the support

plate cannot exceed 100 MPa, and the bearing stress between the rod head and the support plate cannot exceed 145 MPa. Determine

the maximum value of Pmax that can be supported by the structure.

Support

Plate

Hole diameter D

a

Rod

b.

Answer: Pmax= i

-0

Head

KN

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The d = 14-mm-diameter solid rod passes through a D = 19-mm-diameter hole in the support plate. When a load Pis applied to the rod, the rod head rests on the support plate. The support plate has a thickness of b = 11 mm. The rod head has a diameter of a = 28 mm, and the head has a thickness of t = 8 mm. The shear stress in the rod head cannot exceed 130 MPa, the punching shear stress in the support plate cannot exceed 95 MPa, and the bearing stress between the rod head and the support plate cannot exceed 125 MPa. Determine the maximum value of Pmax that can be supported by the structure. Support Plate - Hole diameter D Rod Нead b -arrow_forwardThe bell-crank mechanism is in equilibrium for an applied load of F₁ = 18 kN applied at A. Assume a = 270mm, b = 150mm, c = 70mm, and 0= 50°. Pin B is in a double-shear connection and has a diameter of 33 mm. The bell crank has a thickness of 39 mm. Determine (a) the shear stress in pin B. (b) the bearing stress in the bell crank at B. Support bracket F₁ Answers: Ob Tpin B = Bell crank Bu CI B MPa MPa F₂arrow_forwardThe assembly is used to support a distributed loading of w = 6.6 kN/m. The solid steel rod BC has a diameter of 13 mm and the steel pins at A, B and C have a diameter of 10 mm. The yield stress of the steel in tension is 250 MPa and in shear is 125 MPa. C 1.2 m 0.9 m 0.3 m Determine the factor of safety for the pin at B with respect to yielding? Input your answer to two decimal places.arrow_forward

- A suspension system of a mountain bike is held by a pin at point C and supported by a shock absorber BD. If the bike is designed to withstand a load P = 1500N with safety factor F₁ = 2, ultimate shear stress t = 150 MPa and ultimate tensile stress Ou = 360 Mpa, determine pin B and pin C diameters.arrow_forwardThe five-bolt connection must support an applied load of P = 1800 lb. If the average shear stress in the bolts must be limited to 47 ksi, determine the minimum bolt diameter that may be used for this connection.arrow_forwardThe bell-crank mechanism is in equilibrium for an applied load of F1 = 11 kN applied at A. Assume a = 250mm, b = 100mm, c = 90mm, and θ = 40°. Pin B is in a double-shear connection and has a diameter of 29 mm. The bell crank has a thickness of 31 mm. Determine the shear stress in pin B. Express your answer in MPa rounded to the nearest hundredths.arrow_forward

- The 10-mm-diameter steel bolt in (Figure 1) is surrounded by a bronze sleeve . The outer diameter of this sleeve is 20 mm, and its inner diameter is 10 mm. Est = 200 GPa, Epr 100 GPa. Part A If the bolt is subjected to a compressive force of P = 15.7 kN, determine the average normal stress in the steel. Express your answer to three significant figures and include appropriate units. Ost = Value MPа Submit Request Answer Part B If the bolt is subjected to a compressive force of P = 15.7 kN, determine the average normal stress in the bronze. Express your answer to three significant figures and include appropriate units. Figure HA P Obr = Value MPа Submit Request Answer 10 mm Provide Feedback 20 mm Parrow_forwardPlease help me answer this asap thank youarrow_forwardThree metal rods are firmly attached to the walls and the middle rigid plate. Rod AB is made from stainless steel and rods CD and EF are made from 2014-T6 aluminum. If a balanced load is applied to the rigid plate, determine what the stresses are in the rods. Follow the sign convention that tensile stress is positive and compressive stress is negative. The parameter values are listed in the table above the figure. A parameter value units 470 mm 400 mm 40 mm 30 mm 30 KN cc 080 BY NO SA 2021 Cathy Zupke L₁ L2 d₁ d₂ P 4₁ B C E The stress in AB σAB= The stress in CD and EF: OCD = EF= d₂ L₂ MPa D F MPaarrow_forward

- An axial force of 52 kN is applied to the assembly shown by means of rigid end plates. 5 mm 5 mm 20 mm 20 mm 5 mm 5 mm Steel core E = 200 GPa Brass shell E = 105 GPa 250 mm Determine the normal stress in the brass shell. The normal stress in the brass shell is MPа.arrow_forwardThe bar has a cross-sectional areao of 490(10-6)m2. It is subjected to triangular axial distributed loading along its length which is 0 at x= 0 and 9 kN/m at x= 1.5 , and to two concetrated loads Determine the average normal stress in the bar as a function of x for 0 <_x < 0.6marrow_forwardA compound shaft consists of an aluminum tube (1) securely jointed to a steel tube (2). Both aluminum and steel tubes have an outside diameter of D= 48 mm and a wall thickness of t= 3 mm. The shaft is secured by a fixed support at one end and is subjected to a torque of T= 115 N.m at the other end. Determine the maximum stress in the shaft.[L1 = 200 mm, L2 = 350 mm, D = 48 mm , t = 3 mm, G = 75 GPa]arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY