Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

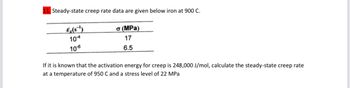

Transcribed Image Text:11. Steady-state creep rate data are given below iron at 900 C.

Es(s)

104

10-6

o (MPa)

17

6.5

If it is known that the activation energy for creep is 248,000 J/mol, calculate the steady-state creep rate

at a temperature of 950 C and a stress level of 22 MPa

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The flow stress of a coarse-grained dilute copper alloy increased from 2 to 55 MPa when the dislocation density was increased from a low value of 10 cm via cold working to a modest value of 100 cm2. Calculate the flow stress for this alloy when heavy cold working introduces a dislocation density of 10¹2 cm². An equation similar to the Hall-Petch equation has been proposed for dislocations, and is: Tflow To ka Paisl where Tflow is the flow stress (i.e., the force per unit area necessary to get plastic deformation), pdisi is the dislocation density (the dislocation line length per unit volume), and To and ka are constants for a given material. The easiest way to solve this problem is to put values into this equation twice, subtract one expression from the other, and solve for ka. Then enter your value of ka into either original equation to determine To. Keep track of units, and then solve the problem stated above.arrow_forwardSintered silicon nitride parts are expected to experience tensile stresses 50% of the ultimate tensile strength of the material. What will be the maximum allowable size of internal flaws for these parts not to fail in service? Given the following properties of the material: Specific surface energy: 0.3 J/m2 its Youngs Modulus: 304 GPa Ultimate tensile Strength: 570 MPa Select one: a. 1.43 µm b. 0.71 µm c. 15 µm d. 85 µm e. 9.5 µmarrow_forwardEstimate the theoretical fracture strength of a brittle material if it is known that fracture occurs by the propagation of an elliptically shaped surface cra of length 0.5 mm and having a tip radius of curvature of 0.005 mm, when a stress of 1040MPa is applied. Your answer must be in GPa. Write your answer to 1 decimal place. Answer: V 30 (0) 00 a W 4340 steel alloy. Determine the ductile to brittle transitionarrow_forward

- q11arrow_forwardRank the ceramic materials in the table according to their thermal shock resistance. Which material from the table do you choose for thermal cycling application in 200 - 900°C temperature range? Show your work.arrow_forwardIn designing a ceramic part for a jet engine, to ensure that the part does not fail, we plan to ensure that the maximum applied stress is only one-third of the yield strength. The yield strength of this CMC part for a jet engine is 520 MPa, and its plane strain fracture toughness is 5.5 MPa√?. We utilize a nondestructive test to find any internal faults that are longer than 1.27 mm. Does our non-destructive test have the requisite sensitivity if Y = 1.4? Explain.arrow_forward

- Ductility (%EL) 70 60 50 40 30 20 10 Brass 1040 Steel 10 Copper 20 30 40 50 Percent cold work 60 70 Percent cold work = 0 Ductility = 0arrow_forwardHelp me pleasearrow_forward1. For the stress-strain curve shown below, please estimate the properties indicated. (a) Fracture Strain Please do your work on a separate sheet of paper, and put your answers in the boxes on the right. Be sure to include the proper symbol and units. Stress Strain 70 60 50 Stress (ksi) 240 30 20 10 70 0 0.000 60 50 Stress (ksi) 40 20 10 KULL 0 0.000 0.010 0.050 0.100 Strain (in/in) Stress Strain 0.020 0.030 Strain (in/in) 0.040 0.150 0.050 (b) Ultimate Tensile Stress (c) Fracture Stress (d) Proportional Limit (e) Elastic Modulus (1) Yield Stress (g) Tensile Toughness (Modulus of Toughness) (h) Modulus of Resiliencearrow_forward

- The properties of a titanium allow used in commercial airplanes are shown in the table: Strength (MPa) Grain Size (mm) 0.020 162 0.055 148 Determine a) the constants of the Hall-Petch equation and b) the grain size required to obtain a strength of 192 MPaarrow_forwardi need the answer quicklyarrow_forwardIn the Table below Data for Mar M 247-a Nickel base superalloy is shown. (1) Plot the steady state strain rate and time to rupture to predict a relationship between the two variables. Provide an equation for the relationship that you see. (2) Give an explanation as to why the fracture elongation is going up with stress.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY