Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:Industry Print Exercise 23-2

Refer to print PR 23-2. The sequence of operations for this print is given below. Answer the questions

following the sequence of operations.

Sequence of Operations

descends at a controlled rate, slowly compacting the explosive charge to avoid detonation due to a sudden

Description: This is a system to control a 90-ton hydraulic, explosive-compaction press. The press ram

shock.

1. The cycle is started by energizing solenoid A, which shifts control valve 3 and supplies pressure to the

head end of the hydraulic cylinder (7). This operates the ram.

2. The cylinder (7) extends at a slow rate controlled by the fluid in the rod end of the cylinder, which is

vented through the flow control valve (5).

the

1. When

de-energizes solenoid A and energizes solenoid B. This shifts control valve 3 to retract the cylinder (7).

de rol valve 5 has an integral check valve that permits the free flow of fluid in the opposite direction,

causing the cylinder (7) to rapidly retra

retract.

4. The retraction of the cylinder (7) actuates the limit switch (8), which de-energizes solenoid B. Control

valve 3 returns to the neutral position. This completes the cycle. This circuit has safety features.

On electrical power outage, both solenoid A and solenoid B are de-energized. This allows valve 3 to

return to the center position, thus stopping ram travel. Also, valve 4 provides low-pressure relief on the

ram upstroke, and valve 2 provides high-pressure relief on the ram downstroke.

Questions

1. What is the name of the circuit?

2. How many reservoir symbols are shown, and how many reservoirs are there?

3. What starts the sequence of operations?

4. When valve 3 shifts on due to the energizing of solenoid A, to which end of the cylinder (7) is pressure

supplied?

5. What causes the ram to extend at a slow, controlled rate?

6. What causes the ram to retract?

7. Why does the cylinder (7) retract rapidly?

514

Section 5 Specialized Parts and Prints

8. What completes the cycle?

9. What happens in the event of electrical power outage?

10. Give the function of valves 2 and 4.

513

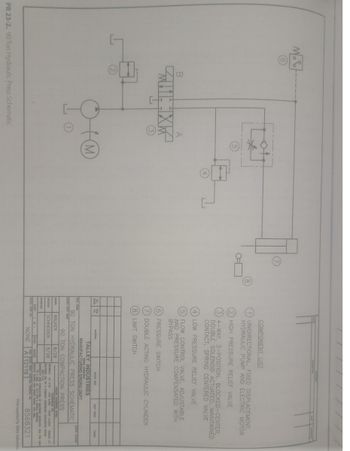

Transcribed Image Text:B

XK

PR 23-2. 90 Ton Hydraulic Press Schematic

5

(M)

(2) HIGH PRESSURE RELIEF VALVE

(3) 4-WAY, 3-POSITION, BLOCKED-CENTER,

DOUBLE SOLENOID ACTUATED, MAINTAINED

CONTACT, SPRING CENTERED VALVE

(4) LOW PRESSURE RELIEF VALVE

FLOW CONTROL VALVE, ADJUSTABLE

AND PRESSURE COMPENSATED WITH

BYPASS

6) PRESSURE SWITCH

(7) DOUBLE ACTING HYDRAULIC CYLINDER

(8) LIMIT SWITCH

REDD NEM

CHECKED

TOOL NAME

COMPONENT LIST

UNIDIRECTIONAL, FIXED DISPLACEMENT,

HYDRAULIC PUMP AND ELECTRIC MOTOR

APPROVED

SHEET

MATERIAL

STOCK SIZE

TALLEY INDUSTRIES

MESA, ARIZONA

MANUFACTURING ENGRG DEPT

90 TON HYDRAULIC PRESS SCHEMATIC

90 TON COMPACTION PRESS

8/28

8/28

WALKER

SCHNEIDER

SCALE NONE

NONE A 12116

200 300 002 000 0002 ANGLES at

COMMON CONTORNE CONCENTRIC whos

REMOVE BURS NO SAP EDES 230 MAK

8568321

Print supplied by Talley Industries

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A domestic refrigerator is placed in an insulated closed room. If the unit operates with the door open which of the following statements are true for the case. There may be greater then one correct answer. Select one or more: O a. The temperature of the room will rise. O b. None of the statements are true for such a case. O c. The temperature of the room will fall. O d. The internal energy of the room will increase.arrow_forwardQuestion 7 What is vacuum pressure? "It is the pressure above the atmospheric pressure, measured using a gauge." "It is the pressure below the atmospheric pressure, measured using a gauge." It is the sum of the atmospheric and gauge pressures. It is the pressure of the atmosphere.arrow_forwardQuestion Two: The crank shaft of an engine runs at 2400 rpm. If it takes 0.002 second after ignition for the charge to gain maximum pressure, what should the crank angle be when spark occurs. If the inlet valve opens 12° before T.D.C. and closes 43° after B.D.C. for how long is it open during one cycle?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY