Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

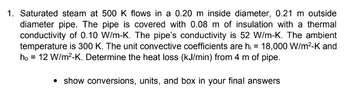

Transcribed Image Text:1. Saturated steam at 500 K flows in a 0.20 m inside diameter, 0.21 m outside

diameter pipe. The pipe is covered with 0.08 m of insulation with a thermal

conductivity of 0.10 W/m-K. The pipe's conductivity is 52 W/m-K. The ambient

temperature is 300 K. The unit convective coefficients are h; = 18,000 W/m²-K and

ho = 12 W/m²-K. Determine the heat loss (kJ/min) from 4 m of pipe.

• show conversions, units, and box in your final answers

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A chip that is of length L = 5.5 mm on a side and thickness t = 2.0 mm is encased in a ceramic substrate, and its exposed surface is convectively cooled by a dielectric liquid for which h = 150 W/m² K and To = 20°C. . Th Chip, q, T₁, P, Cp The time is Substrate In the off-mode the chip is in thermal equilibrium with the coolant (T; = T). When the chip is energized, however, its temperature increases until a new steady state is established. For purposes of analysis, the energized chip is characterized by uniform volumetric heating with a = 9 x 106 W/m³. Assuming an infinite contact resistance between the chip and substrate and negligible conduction resistance within the chip, determine the steady-state chip temperature Tƒ. Following activation of the chip, how long does it take to come within 1°C of this temperature? The chip density and specific heat are p = 2000 kg/m³ and c = 700 J/kg-K, respectively. The steady-state chip temperature Tf is i S. °C.arrow_forwardTo maximize production and minimize pumping costs, crude oil is heated to reduce its viscosity during transportation from a production field. (1) Consider a pipe-in-pipe configuration consisting of concentric steel tubes with an intervening insulating material. The inner tube is used to transport warm crude oil through cold ocean water. The inner steel pipe (k, = 45 W/m-K) has an inside diameter of D;, 1 = 150 mm and wall thickness t; = 20 mm while the outer steel pipe has an inside diameter of D;, 2 = 250 mm and wall thickness t, = t;. Determine the maximum allowable crude oil temperature to ensure the polyurethane foam insulation (kp = 0.03 W/m-K) between the two pipes does not exceed its maximum service temperature of T, max = 70°C. The ocean water is at T,o = -5°C and provides an external convection heat transfer coefficient of h, = 500 W/m²-K. The convection coefficient associated with the flowing crude oil is hị = 450 W/m²-K. (2) It is proposed to enhance the performance of the…arrow_forward16-26 In a certain experiment, cylindrical samples of diameter 4 cm and length 7 cm are used (see Fig. 16–9). The two thermocouples in each sample are placed 3 cm apart. After initial transients, the electric heater is observed to draw 0.6 A at 110 V, and both differential thermometers read a temperature difference of 8°C. Determine the thermal con- ductivity of the sample. Answer: 98.5 W/m.Karrow_forward

- Hot fluid "C= 2562 J/kg.k, Pr=51.3, µ = 5.22E-3 Pa.s,k= 0.260 W/m.K" flows at 1.3 kg/min inside a 3-mm diameter, thin- %3| walled tube. The tube is coiled and submerged in a water bath maintained at 23°C. The fluid experiences a temperature drop of 60°C and leaves the tube at 35°C. What is the heat transfer rate "Watts"? Neglect heat transfer enhancement associated with the coiling. Assume fully developed flow, if turbulent flow use Dittus Boelter equation: Nu = 0.023 Re 0.8 Pr. Select one: А. 3630.4 B. 4196.6 C. 2964.2 D. 3930.1 Е. 3330.6arrow_forwardNeed help I'm not sure where I went wrong on thisarrow_forwardThe interior of a refrigerator whose dimensions are 0.05 x 0.05 dam base area and 1.25 m high, must be kept at 4 °C. The refrigerator walls are constructed of two steel sheets (k= 35 kcal/h.m.°C) 3 mm thick, with 65 mm of material insulation (k=0.213 kcal/h.m.°C) between them. The film coefficient of the inner surface is 10 kcal/h.m².°C, while on the external surface it varies from 8 to 12.5 kcal/h.m².°C. Calculate: a) The power (in HP) of the refrigerator motor so that the heat flux removed from the inside the refrigerator maintain the specified temperature, in a kitchen whose temperature can vary from 21 to 36 °C; b) The temperatures of the inner and outer surfaces of the wall. Given 1 HP = 641.2 Kcal/harrow_forward

- can you please please work it all outarrow_forwardDefine: a. Convection heat transfer coefficient b. Loss of pressure across the tube arrangement *)Based on image below:arrow_forwardBased on the picture above, make a schematic and determine the average temperature difference over the entire length of the tube (ATLM). (value 25)arrow_forward

- 4. For a thermally fully developed flow in a pipe for a fluid with constant properties, the local convection coefficient (a) Decreases as x-1/2 (b) Decreases as x-1/5 (c) Increase as x1/2 (d) Increases as x4/5 (e) Remains constantarrow_forwardA thick-walled cylindrical tubing of hard rubber (k=0.151 W/m*K) having an inside radius of 5 mm and an outside radius of 20 mm is being used as a temporary cooling coil in a bath. Ice water is flowing rapidly inside, and the inside wall temperature is 275 K. The outside surface temperature is 300 K. A total of 20 W must be removed from the bath by the cooling coil. How many meter of tubing are needed?arrow_forwardA type 316 stainless steel pipe has a 6 cm inside diameter and an 8 cm outside diameter with a 2 mm layer of 85% magnesia insula- tion around it. Liquid at 112°C flows inside with h = 346 W/m²K. The air around the pipe is at 20°C, and h, = 6 W/m²K. Calculate U based on the inside area. Sketch the equivalent electrical circuit, showing all known temperatures. Discuss the results and suggest an improved design. [To = 96.36°C] %3Darrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY