Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

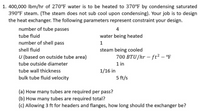

Transcribed Image Text:1. 400,000 Ibm/hr of 270°F water is to be heated to 370°F by condensing saturated

390°F steam. (The steam does not sub cool upon condensing). Your job is to design

the heat exchanger. The following parameters represent constraint your design.

number of tube passes

4

tube fluid

water being heated

number of shell pass

shell fluid

steam being cooled

U (based on outside tube area)

700 BTU/hr – ft² – °F

1 in

tube outside diameter

tube wall thickness

1/16 in

bulk tube fluid velocity

5 ft/s

(a) How many tubes are required per pass?

(b) How many tubes are required total?

(c) Allowing 3 ft for headers and flanges, how long should the exchanger be?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- An electric hot water heater consumes 3.1 kilowatts of electricity and converts it to heat. How long will it take the water heater to heat a 67 gallon tank of water from 10 degrees Celsius to 50 degrees Celsius? (1 kilogram of water is 0.37 gallons, 1 Calorie = 4200 J). It may be helpful to refer back to the weekly handout for guidance on this problem. Your final answer should be in minutes (rounded to the nearest 10 minutes).arrow_forwardProblem 5. A 1000 cubic foot room is initially at standard temperature and pressure. A resistance heater in the room is consuming 1500W of electricity. What is the air temperature of the room after 3 hours? Assume the room acts as an isolated system. Hint: The specific heat of a substance is the amount of heat it takes to warm one unit mass of material by one degree. The specific heat of air (assuming constant volume) can be taken as C₂ = 700J/kg°C. This relates the total heat added to the system to its temperature rise.arrow_forwardA hot water leak in one of the faucets of your apartment can be very wasteful. A continuous leak of one quart per hour (a "slow" leak) at 155 degrees°F causes a loss of 1.81 million Btu per year. Suppose your water is heated with electricity. a. How many pounds of coal delivered to your electric utility does this leak equate to if one pound of coal contains 12,000 Btu and the boiler combustion process and water distribution system have an overall efficiency of 28%? b. If a pound of coal produces 1.81 pounds of CO2 during the combustion process, how much extra carbon dioxide does the leaky faucet produce in a yeararrow_forward

- A conditioned space has a calculated heat loss at the design maximum heating day of 10,000 BTUs / Hr to maintain an interior temperature of 70 F. We will use a hydronic baseboard style convector to heat the space. The style we have chosen comes in standard lengths. At rated temperature and flow of hydronic heating fluid for each 1 foot of length the heater will add 750 BTUs /Hr to the room. What length of heater can just maintain the temperature on the worst day? For this example we are ignoring other sources of heat loss such as ventilation or drafts.arrow_forwarda. An air stream passing through a 2-inch (1/6 ft) diameter, thin-walled tube is to be heated by high- pressure steam condensing on the outer surface of the tube at 320 °F. The overall heat transfer coefficient, h between steam and air can be assumed to be 25 Btu/(ft2.hr °F) with the air entering at 100 ft/sec, 10 psia, 40 °F. The air is to be heated to 150 °F. Determine the tube length required. Assuming Rayleigh Line flow, calculate the static pressure change due to heat addition. Also, for the same inlet conditions, calculate the pressure drop due to friction, assuming Fanno flow in the duct with f = 0.018. b. c. d. To obtain an approximation to the overall pressure drop in this heat exchanger, add the two results. Discuss the accuracy of this calculation.arrow_forwardPls. Answer thank you! An auditorium is designed to seat 4500 people. The ventilation rate is 1.62×107 ft³/hr of outside air. The outside temperature is 0°F dry bulb, and outside pressure is 14.6 psia. Air leaves the auditotium at 70°F dry bulb. There is no recirculation. The furnace has a capacity of 1,250,000 Btu/hr. The temperature at which the air should enter the auditorium is most nearly?arrow_forward

- Q.2 The following data relates to the office air conditioning plant having maximum seating capacity of 25 occupants : Recirculated air Room Outside air 4) to = 34°C tm = 28°C ta2 = 24°C $2 = 50% Mixing Coil Outside design conditions: 34°C DBT, 28°C WBT Inside design conditions: 24°C DBT, 50% RH Solar heat gain= 9120 W Latent heat gain per occupant= 105w Sensible heat gain per occupant=90w Lightening load= 2300 W Sensible heat load from other sources= 11630 W Infiltration load= 14 m³/min Assuming 40% fresh air and 60% of recirculated air passing through the evaporator coil and the by-pass factor of 0.15. Draw the process on psychrometric chart and find the dew point temperature of the coil and capacity of the plant.arrow_forwardNOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. A steam power plant receives heat from a furnace at a rate of 280 GJ/h. Heat losses to the surrounding air from the steam as it passes through the pipes and other components are estimated to be about 8 GJ/h. The waste heat is transferred to the cooling water at a rate of 170 GJ/h. Problem 06.017.a - Net power output of steam power plant Determine the net power output. (You must provide an answer before moving to the next part.) The net power output is MW.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY