Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

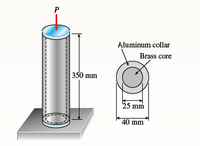

A cylindrical assembly consisting of a brass

core and an aluminum collar is compressed by a load

P (see figure). The length of the aluminum collar

and brass core is 350 mm, the diameter of the core

is 25 mm, and the outside diameter of the collar is

40 mm. Also, the moduli of elasticity of the aluminum

and brass are 72 GPa and 100 GPa, respectively.

(a) If the length of the assembly decreases by 0.1%

when the load P is applied, what is the magnitude

of the load?

(b) What is the maximum permissible load Pmax if

the allowable stresses in the aluminum and brass

are 80 MPa and 120 MPa, respectively?

Transcribed Image Text:Aluminum collar

Brass core

350 mm

25 mm

40 mm

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 2-A wheel of diameter d and width w carrying a load F rolls on a flat rail. Estimate the maximum contact pressure for these materials. Por vedit -3D d 5 in 150 mm 3 in W 2 in 40 mm 1.25 in F 600 lbf 2 kN 250 lbf Wheel Material Steel Steel Cast iron Rail Material Steel Cast iron Cast iron.arrow_forwardExample:- A three 1in *3in wood board is connected together by bolt (d=0.5in) as shown in the figure. The washer dimensions are (Do-2in, Di-0.5in). The nut is a 0.5in (Zinc Finish, grade A Finished Hex. Nut). Analyze the stress developed in the wood and the bolt in the following two cases :- Case I:-An External force of (P=1400lb) that is applied on the wood board on the right is transmitted through the bolt to left wood board. - Case II: There is no external force but the nut is tightened so that internal stress of o=2700psi is developed in the bolt. 돌 - P/2 -F P/2 NT NTarrow_forward3. The bar shown below is composed of two pieces, AC and CD. The bar is attached to the wall at point A. The length L = 10 in. The cross sectional areas are: AAC = 4 in? and AcD = 2 in?. The Young's Moduli are: EAC =20 Msi and Ecd= 15 Msi Two forces are applied at points B and D: PB = 50 kips and PD = 20 kips. Determine: (a) the reaction force at A (specify –→ or +) and (b) the deflection of point D (specify → or +). (Hint for (b): Think about how many pieces you must subdivide the rod into.) Ans: RA = 30 kips (+), dp = 7.9167×10-3 in (E) A В C D Pp L 2L Larrow_forward

- 5. (a) (b) (c) Koo D d An Aluminium alloy (6061-T6) circular tube (Fig.Q5) used for vehicle fittings is under axial compression. The tube has a length L = 5m, outer diameter D = 65mm and inner diameter d = 55mm. The Young's modulus of Aluminium alloy 6061-T6 is E= 68.9 GPa and yield strength ay = 276 MPa. Determine the buckling load with the Euler formula, assuming the tube to be pin-jointed at the two ends Determine the buckling load with the Euler formula, assuming the tube to be fixed at the two ends Assuming the tube to be pin-jointed at both ends, determine the length of the tube, below which the Euler formula is no longer valid Fig.Q5 L-arrow_forwardProblem 15 The compound bar shown below is made of a light, strong material with E= 70,000 N/mm². Two forces are applied to the rigid plates connecting the bars. The yield strength is o, = 200 N/mm². The bar has a rectangular cross section with height H = 12.5 mm and thickness t = 1.0 mm. You may neglect the weight of the bars. (a) Calculate the x-direction internal force in segments AB and BC of the compound bar. Show all work. (b) Calculate the total length change of the compound bar. (c) The plane 1-2 represents a lap joint. Calculate the normal stress on the lap joint. L₂= 625 mm A L₁ = 775 mm H = 12.5 mm X 1800 N B 1 H = 12.5 mm =35° 2 F₂ = 1000 N Cross section H-12 H = 12.5 mm t = 1.0 mmarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY