Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

Help with this

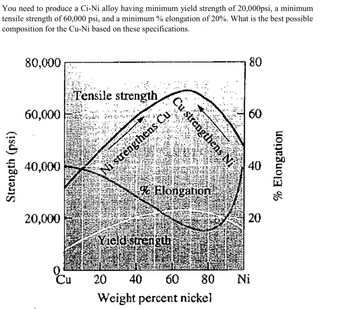

Transcribed Image Text:**Objective:**

To produce a Cu-Ni alloy with:

- Minimum yield strength of 20,000 psi

- Minimum tensile strength of 60,000 psi

- Minimum elongation of 20%

**Graph Explanation:**

The graph plots the mechanical properties of Cu-Ni alloys against the weight percent of nickel (Ni) ranging from 0% (pure copper) to 100% (pure nickel). The x-axis represents the weight percent of nickel, while the y-axis has two separate scales: strength (psi) on the left and percent elongation on the right.

**Curves:**

1. **Yield Strength Curve:**

- Starts at around 10,000 psi for 0% Ni and increases gradually with more nickel content.

2. **Tensile Strength Curve:**

- Begins at approximately 40,000 psi for 0% Ni, rises steeply, peaking around 70,000 psi near 50% Ni, then declines slightly with more nickel.

3. **% Elongation Curve:**

- Starts high at about 60% elongation for 0% Ni, decreases sharply, reaches a minimum near 40% Ni, and then increases again.

**Optimal Composition:**

To achieve the specified requirements for yield strength, tensile strength, and % elongation, the optimal composition is around 30-40% Ni. This range balances the higher tensile strength and acceptable yield strength while maintaining a good percentage of elongation.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- (The objective paragraph should extend and mention the specific point to reach the goal) the report talking about system ventilation.. i need a paragraph about this about 4 lines Bireflyarrow_forwardProblem- Cargo ships can cause a lot of air pollution.Solution- to use nuclear powered ships since they hold a lot of energy and can travel for long distances. How it will work is that it will need a nuclear reactor at the bottom of the boat to heat up the water and then turn it to electricity to power the boat. The boat will be made out of graphene which is a tough material to avoid any leaks in the boat. It will also contain many control rods because nuclear power is so powerful that it can create to much energy to handle. With control rods, you can slow down this process and keep it in a controlled manner. Since cargo ships are already is the ocean, there will be no need for any extra materials to make it work. -Do you think this will work? Why/Why not? -What do you think is wrong with it/ How can this be improved? Please send this to someone else I need to record 50 responses for a science project. Thank you!arrow_forwardwhy is the actual weight is lower than the theoretical weightarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY