Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:Select one:

О а. 75 МPа, 3x105 Суcles

О Б. 75 МРа, 9х105 Суcles

75 MPа, 4x10° Сycles

С.

O d. 400 MPa, 5x10° Суcles

O e.

200 MPа, 3x105 Сycles

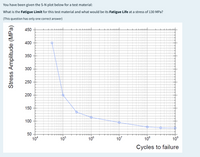

Transcribed Image Text:You have been given the S-N plot below for a test material:

What is the Fatigue Limit for this test material and what would be its Fatigue Life at a stress of 130 MPa?

(This question has only one correct answer)

450

400

350

300

250

200

150

100

50

104

105

106

10

108

10°

Cycles to failure

Stress Amplitude (MPa)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- You have been given the following test sample data following mechanical testing of 15 test pieces of a modified Alumina. What is the Weibull modulus of this material? Would you advise the use of this material over one with a Weibull Modulus of 19.6 and a mean failure stress of 270 MPa, if you anticipate that the peak stress on the material could be 255 MPa? Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Select one or more: a. 185 b. No Yes □d. 49 □e. 28.6 3.7 Failure Stress (MPa) 297 293 270 300 g. 22.8 260 296 265 295 280 288 263 290 298 275arrow_forward1- what materials are included here (z parameter), type of materials considered, property or properties plotted, domain of c, parameter identified 2- what are the vertical and horizontal trends presented 3-what is the take away story from this plot please answer i will upvotearrow_forwardA structural component in the form of a wide plate is to be fabricated from a steel alloy that has a plane strain fracture toughness of 88 MPam (ksi √/in.)) and a yield strength of 880 MPa (63820 psi). The flaw size resolution limit of the flaw detection apparatus is 3 mm (0.1181 in.). (a) If the design stress is one-half of the yield strength and the value of Y is 1.11, what is the critical flaw length? i mm (b) On the basis of this value, is a critical flaw subject to detection?arrow_forward

- 1. For the stress-strain curve shown below, please estimate the properties indicated. (a) Fracture Strain Please do your work on a separate sheet of paper, and put your answers in the boxes on the right. Be sure to include the proper symbol and units. Stress Strain 70 60 50 Stress (ksi) 240 30 20 10 70 0 0.000 60 50 Stress (ksi) 40 20 10 KULL 0 0.000 0.010 0.050 0.100 Strain (in/in) Stress Strain 0.020 0.030 Strain (in/in) 0.040 0.150 0.050 (b) Ultimate Tensile Stress (c) Fracture Stress (d) Proportional Limit (e) Elastic Modulus (1) Yield Stress (g) Tensile Toughness (Modulus of Toughness) (h) Modulus of Resiliencearrow_forwardYou have been given the following test sample data following mechanical testing of 15 test pieces of Silicon Nitride. What is the Weibull modulus of this material? Would you advise the use of a similar material with a Weibull Modulus of 16.3 and a mean failure stress of 485 MPa, if you anticipate that the peak stress on the material could be 430 MPa? Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Select one or more: O a. No O b. 18.6 O C. 13.4 O d. Yes O e. 15.7 f. 17.1 Failure Stress (MPa) 423 459 496 432 447 467 473 499 485 479 505 530 526 490 510 <arrow_forwardThe creep data have been taken on an ahuminum alloy at 400°C and constant stress of 25MPA are shown in below Table, Find the steady state or minimum creep rate. Time (min) strain Time (min) 16 strain 0.135 0.0 0.0 2 0.025 18 0.153 4 0.043 0.065 20 0.172 0.193 0.218 22 0.078 24 10 0.092 26 0.255 12 0.109 28 0.307 14 0.120 30 0.368arrow_forward

- Question 2 Figure 2 shows the dependence of fatigue strength on testing cycles (S-N curve) of an acetal polymer. 60 50 40 30 20 10 104 105 106 107 108 Number of cycles to failure Figure 2 The S-N fatigue curve for an acetal polymer a. What is the fatigue strength, or maximum stress amplitude, at one million cycles of loading? b. An acetal polymer 30-cm-long bar with a diameter of 20 mm is designed to survive one million cycles of loading, what is the maximum allowable axial load that can be applied on one end of the bar? Magnitude of stress Reversal, MPaarrow_forwardplease helparrow_forwardA cylindrical steel bar 8 mm in diameter is loaded 1000 cycles per day with a load of 15560 N. How long until fatigue failure takes place? Note: stress = force/area Group of answer choices The bar should not fatigue. The bar will fail in one cycle. 100 days 1000 daysarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY