Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

I need help answering this

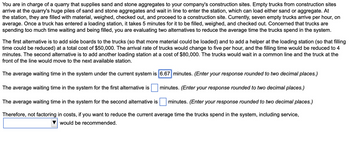

Transcribed Image Text:You are in charge of a quarry that supplies sand and stone aggregates to your company's construction sites. Empty trucks from construction sites

arrive at the quarry's huge piles of sand and stone aggregates and wait in line to enter the station, which can load either sand or aggregate. At

the station, they are filled with material, weighed, checked out, and proceed to a construction site. Currently, seven empty trucks arrive per hour, on

average. Once a truck has entered a loading station, it takes 5 minutes for it to be filled, weighed, and checked out. Concerned that trucks are

spending too much time waiting and being filled, you are evaluating two alternatives to reduce the average time the trucks spend in the system.

The first alternative is to add side boards to the trucks (so that more material could be loaded) and to add a helper at the loading station (so that filling

time could be reduced) at a total cost of $50,000. The arrival rate of trucks would change to five per hour, and the filling time would be reduced to 4

minutes. The second alternative is to add another loading station at a cost of $80,000. The trucks would wait in a common line and the truck at the

front of the line would move to the next available station.

The average waiting time in the system under the current system is 6.67 minutes. (Enter your response rounded to two decimal places.)

minutes. (Enter your response rounded to two decimal places.)

minutes. (Enter your response rounded to two decimal places.)

The average waiting time in the system for the first alternative is

The average waiting time in the system for the second alternative is

Therefore, not factoring in costs, if you want to reduce the current average time the trucks spend in the system, including service,

would be recommended.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps with 6 images

Knowledge Booster

Similar questions

- How can a payroll provider be reliable by providing a service as promised?arrow_forwardCoordination is a fundamental aspect of teamwork and organizational efficiency. It involves the integration of efforts, resources, and activities to achieve common goals. Effective coordination ensures that different parts of an organization or team work together harmoniously, minimizing duplication of effort and maximizing synergy. It involves communication, collaboration, and alignment of objectives across various departments, teams, or individuals. By fostering coherence and unity of purpose, coordination enhances productivity, facilitates problem-solving, and promotes innovation within an organization Question: How can organizations improve coordination among diverse teams working on different projects simultaneously?arrow_forwardcompare redundancy with retirementarrow_forward

- Can information systems aid an organization's objectives?arrow_forwardStaffing is a critical component of organizational success, encompassing the processes of recruitment, selection, training, and retention of personnel. The effectiveness of staffing directly impacts a company's ability to achieve its goals and objectives. A well-designed staffing strategy involves identifying the right talent, placing them in suitable roles, and ensuring ongoing development to enhance their skills and productivity. It is not only about filling positions but also about creating a workforce that aligns with the organization's culture and values. Effective staffing contributes to employee satisfaction, which in turn leads to higher retention rates and a positive organizational climate. In today's dynamic business environment, the role of staffing has become even more crucial as organizations strive to adapt to changes and stay competitive. In light of this, how can organizations strike a balance between attracting new talent and nurturing the growth of existing employees…arrow_forwardCoordination in management is the harmonization of activities and efforts within an organization to ensure that all parts work together efficiently towards the achievement of common goals. It involves synchronizing tasks, resources, and processes across different departments or individuals to maintain coherence and avoid conflicts. Effective coordination facilitates smooth workflow, enhances productivity, and fosters collaboration among team members. It requires clear communication channels, mutual understanding of objectives, and continuous monitoring and adjustment of activities to adapt to changing circumstances. By promoting synergy and alignment, coordination enables organizations to optimize their performance and achieve sustainable success. Question: How can clear communication contribute to effective coordination in management?arrow_forward

- Why can having a wide variety of information systems cause issues at work? Is there a solution to these problems?arrow_forwardCurrent Affairs. What is going on in the industry? Research a topic of interest to you that is currently making headlines and discuss how this topic relates to Management Information Systems.arrow_forwardYou'll need to recruit professionals like graphic designers and media producers if you want to start a media firm. Put together a list of the equipment that will be given to the workers in each department, and provide an explanation of why it's needed. When it comes to data, how can they guarantee its security?arrow_forward

- To obtain the most value out of their investments in information technology, businesses should carefully weigh the benefits and drawbacks of implementing solutions that are specifically designed for their sector.arrow_forwardWrite memo You are the manager of WhiteOut, a store that sells snowboarding equipment and clothing. You have seven employees. Since you believed that today would be a light day for sales, you asked only one employee to work. However, suddenly, more customers than you had expected showed up, and you and your employee are overwhelmed. You need help—fast. E‐mailing your other employees might not work, since they aren’t necessarily near a computer. In contrast, you know they all have smartphones. The fastest and most trustworthy way to communicate with them is through instant messaging or text messaging.arrow_forwardHow much is Telecommunications support technicians salary?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.