Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

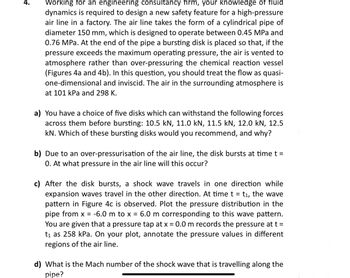

Transcribed Image Text:Working for an engineering consultancy firm, your knowledge of fluid

dynamics is required to design a new safety feature for a high-pressure

air line in a factory. The air line takes the form of a cylindrical pipe of

diameter 150 mm, which is designed to operate between 0.45 MPa and

0.76 MPa. At the end of the pipe a bursting disk is placed so that, if the

pressure exceeds the maximum operating pressure, the air is vented to

atmosphere rather than over-pressuring the chemical reaction vessel

(Figures 4a and 4b). In this question, you should treat the flow as quasi-

one-dimensional and inviscid. The air in the surrounding atmosphere is

at 101 kPa and 298 K.

a) You have a choice of five disks which can withstand the following forces

across them before bursting: 10.5 kN, 11.0 kN, 11.5 kN, 12.0 kN, 12.5

kN. Which of these bursting disks would you recommend, and why?

b) Due to an over-pressurisation of the air line, the disk bursts at time t =

0. At what pressure in the air line will this occur?

c) After the disk bursts, a shock wave travels in one direction while

expansion waves travel in the other direction. At time t = t₁, the wave

pattern in Figure 4c is observed. Plot the pressure distribution in the

pipe from x = -6.0 m to x = 6.0 m corresponding to this wave pattern.

You are given that a pressure tap at x = 0.0 m records the pressure at t =

t₁ as 258 kPa. On your plot, annotate the pressure values in different

regions of the air line.

d) What is the Mach number of the shock wave that is travelling along the

pipe?

Transcribed Image Text:aj

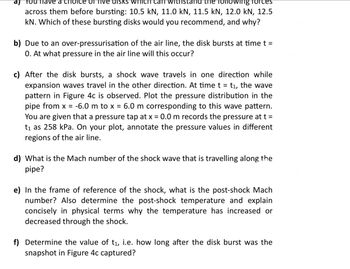

You have a cridice of five disks which can withstand the following forces

across them before bursting: 10.5 kN, 11.0 kN, 11.5 kN, 12.0 kN, 12.5

kN. Which of these bursting disks would you recommend, and why?

b) Due to an over-pressurisation of the air line, the disk bursts at time t =

0. At what pressure in the air line will this occur?

c) After the disk bursts, a shock wave travels in one direction while

expansion waves travel in the other direction. At time t = t₁, the wave

pattern in Figure 4c is observed. Plot the pressure distribution in the

pipe from x = -6.0 m to x = 6.0 m corresponding to this wave pattern.

You are given that a pressure tap at x = 0.0 m records the pressure at t =

t₁ as 258 kPa. On your plot, annotate the pressure values in different

regions of the air line.

d) What is the Mach number of the shock wave that is travelling along the

pipe?

e) In the frame of reference of the shock, what is the post-shock Mach

number? Also determine the post-shock temperature and explain

concisely in physical terms why the temperature has increased or

decreased through the shock.

f) Determine the value of t₁, i.e. how long after the disk burst was the

snapshot in Figure 4c captured?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Read the question carefully and give me right solution according to the question. Note: carefully answer with part Barrow_forwardThe working fluid of the pressure gauge in Fig. 157 is mercury. Estimate the volumetric flow rate in the tube if the fluid flowing through it is (a) gasoline and (b) nitrogen, at 20 ° C and 1 atmarrow_forwardYour team is designing a chemical processing plant. You are the liquid handling and transportation specialist, and you need to transport a solvent (μ = 3.1 cP, ρ = 122k kg/m3) from a storage tank to a reaction vessel. Due to other equipment constraints, the fluid velocity must be 0.8 m/sec, and you must use stainless steel piping (ε = 0.00015 mm) with a total length (L) of 12 m. Determine the pipe inner diameter (ID) you will need to achieve a pressure drop of 0.3 kPa. Use the Moody chart.arrow_forward

- (cc) BY-NO-SA Niel Crews, 2013 An insulated, rigid vessel is initially empty (evacuated). However, it is connected to a steam line that is maintained at 200 psia and 500 °F. The valve is opened until the flow into the tank slows and stops (which occurs when the pressure in the tank is equal to the pressure in the steam line), at which point the valve is closed. What is the temperature within the vessel? °Farrow_forwardsolve it fastarrow_forwardEngine oil (n = 0.20 Pa·s) passes through a fine 2.00-mm-diameter tube that is 10.2 cm long. ▼ Part A What pressure difference is needed to maintain a flow rate of 4.4 mL/min ? Express your answer to two significant figures and include the appropriate units. ΔΡ = 4.76 Submit μA Provide Feedback Pa Previous Answers Request Answer ? X Incorrect; Try Again; 27 attempts remaining Next >arrow_forward

- Don't provide the wrong solution, Humble request.arrow_forwardAs shown in Fig. 4.33, the pipe diameter is d = 25 mm. l1 = 8 m; l2 = 1 m;H = 5 m. The nozzle diameter is d0 = 10 mm, and the minor loss coefficientsof inlet and elbow are f1 = 0.5 and f2 = 0.1 respectively. For nozzle, f3 =0.1 (relative to the outflow velocity of nozzle). The friction factor is k = 0:03.Try to determine jet height h.arrow_forward3. A pump steadily circulates oil used for lubricating heavy machine tools. The volume flow rate and temperature of the oil are 300 gal/min and 104°F, respectively. At 104°F, the kinematic viscosity and the specific gravity of the oil are 2.15 x 10-3 ft² /s and 0.89, respectively. The pipe lengths are 25 ft for the 4-in diameter pipe and 75 ft for the 3-in diameter one. The Schedule-40 steel pipe has an average roughness element size of 0.0018 in. If all minor losses can be ignored, evaluate how much power (in a unit of horsepower) the pump delivers to the oil. 6 ft 22 ft Flow 15 ft Discharge line 3-in Schedule 40 Suction line 4-in Schedule 40 steel pipe steel pipe Pumparrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY