Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

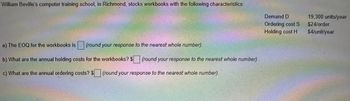

Transcribed Image Text:William Beville's computer training school, in Richmond, stocks workbooks with the following characteristics:

a) The EOQ for the workbooks is (round your response to the nearest whole number).

b) What are the annual holding costs for the workbooks? $ (round your response to the nearest whole number).

c) What are the annual ordering costs? $ (round your response to the nearest whole number).

Demand D

Ordering cost S

Holding cost H

19,300 units/year

$24/order

$4/unit/year

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 4 images

Knowledge Booster

Similar questions

- Ottis, Inc., uses 640,000 plastic housing units each year in its production of paper shredders. The cost of placing an order is $30. The cost of holding one unit of inventory for one year is $15.00. Currently, Ottis places 160 orders of 4,000 plastic housing units per year. Compute the economic order quantity. Economic order quantity = 1600 Compute the ordering, carrying, and total costs for the EOQ. How much money does using the EOQ policy save the company over the policy of purchasing 4,000 plastic housing units per order?arrow_forwardA company has a chance to reduce their inventory ordering costs by placing larger quantity orders using the discount schedule below. What should their optimal order quantity be if this company purchases this single inventory item with an e-mail ordering cost of $4, an annual holding cost rate (per unit) of 2% of the price/unit, and an annual demand of 10,000 units? Order quantity (units) Price/unit ($) 0 to 2,499 1.20 2,500 to 3,999 1.00 4,000 or more 0.98arrow_forwardWhen an firm put aside some extra inventory that serves as an insurance against flucation in demand is called Wastage Inventory O Minimum Level Safety Stock EOQarrow_forward

- In the basic EOQ model, if annual demand doubles, the EOQ will O a. increase by about 41.42 percent O b. decrease by 48.42% O c. double O d. None of these O e. be about 70.7 percent of its previous amountarrow_forwardK William Beville's computer training school, in Richmond, stocks workbooks with the following characteristics: Demand D 19,400 units/year Ordering cost S $27/order Holding cost H $5/unit/year a) The EOQ for the workbooks is 458 (round your response to the nearest whole number) b) What are the annual holding costs for the workbooks? $ (round your response to the nearest whole number).arrow_forwardAbey Kuruvilla, of Parkside Plumbing, uses 1,230 of a certain spare part that costs $24 for each order, with an annual holding cost of $25. Part 2 a) Calculate the total cost for order sizes of 25, 40, 50, 60, and 100 (round your responses to two decimal places). Order Size Total Cost ($) 25 enter your response here 40 enter your response here 50 enter your response here 60 enter your response here 100 enter your response here b) What is the economic order quantity? units (round your response to two decimal places).arrow_forward

- ← William Beville's computer training school, in Richmond, stocks workbooks with the following characteristics: Demand D 19,400 units/year Ordering cost S $27/order Holding cost H $5/unit/year a) The EOQ for the workbooks is 458 (round your response to the nearest whole number). b) What are the annual holding costs for the workbooks? $ 1145 (round your response to the nearest whole number). c) What are the annual ordering costs? $ (round your response to the nearest whole number).arrow_forwardSunrise Garden Center buys 425 bags of fertilizer per month for feeding and weeding lawns. The ordering cost is $15.00. Holding cost is $0.10 per bag per year. a. How many bags should Sunrise order at a time? Sunrise should order bags at a time. (Enter your response rounded to the nearest whole number.) b. What is the time between orders? The time between orders is months. (Enter your response rounded to one decimal place.)arrow_forwardThomas Kratzer is the purchasing manager for the headquarters of a large insurance company chain with a central inventory operation. Thomas’s fastest-moving inventory item has a demand of 6,000 units a year. The purchasing cost of each unit is $16 (additional 5% discount applies if at lease 150 units ordered a time), and the inventory carrying cost is $3 per unit per year. The average ordering cost is $10 per order. It takes about 3 working days for an order to arrive. (This is a corporate operation, and there are 300 working days per year.) Answer the following questions, Q1~Q5. Note that you must include Excel formulas/calculations showing how you arrive at the answer. Q1: Assume that the demand is consistent throughout the year. What is the ROP? Note that stockouts and unnecessary inventory holding should be avoided at any times. Q2: Assume that the demand is consistent throughout the year. Based on the EOQ model, to minimize the costs of purchasing, ordering and inventory holding…arrow_forward

- If annual sales in are 65,000 units, price per unit is $25, carrying costs are 30%, and fixed costs per order is $100, then EOQ is 1,316.56. True or False?arrow_forward3 Which of the following inventory models considers backorder costs? O a. Economic Order Quantity with Quantity Discounts O b. Basic Economic Order Quantity C. Economic Order Quantity with Planned Shortages Od. Economic Production Quantityarrow_forward44 Which of these statements about the production order quantity model is FALSE? Select one: a. The production order quantity model is appropriate when the assumptions of the basic EOQ model are met, except that receipt is noninstantaneous. b. Because receipt is noninstantaneous, some units are used immediately and not stored in inventory. c. All else equal, the smaller the ratio of demand rate to production rate, the larger is the production order quantity. d. Average inventory is less than one-half of the production order quantity. e. None of the above is false.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.