Concept explainers

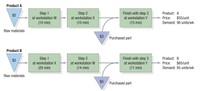

EU Company manufactures two different types of life vests (A and B) that are manufactured and assembled on three different workstations (W, X, and Y) using a small-batch process (see Figure 1). Batch setup times are negligible. The flowchart denotes the path each product follows through the manufacturing process, and each product’s price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. EU can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $6 per hour for an entire week, regardless of how much the worker is used. Total labor costs per week are fixed. Variable overhead costs are $1,500/week. The plant operates one 8-hour shift per day, or 40 hours/week.

- Which of the three workstations, W, X, or Y, has the highest aggregate workload, and thus serves as the bottleneck for EU Company?

- Determine the profit by the bottleneck method advocated by supervisor is used to select the product mix?

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

What TOC method could be used to relieve or improve workflow

What TOC method could be used to relieve or improve workflow

- Consider the bill of materials (BOM) shown to the right. What is the lead time (in weeks) to respond to a customer order for product A, assuming no existing inventories or scheduled receipts? The lead time to respond to a customer order for product A is response as an integer.) weeks. (Enter your C (1) LT=3 B (1) LT=1 D (1) LT=6 A LT=5 E (1) ON LT=5 F (1) LT=3arrow_forwardA linear programming computer package is needed. The Westchester Chamber of Commerce periodically sponsors public service seminars and programs. Currently, promotional plans are under way for this year's program. Advertising alternatives include television, radio, and online. Audience estimates, costs, and maximum media usage limitations are as shown. Constraint Television Radio Online Audience per advertisement 300,000 54,000 120,000 Cost per advertisement $2,000 $300 $600 Maximum media usage 10 20 10 To ensure a balanced use of advertising media, radio advertisements must not exceed 50% of the total number of advertisements authorized. In addition, television should account for at least 10% of the total number of advertisements authorized. (a) If the promotional budget is limited to $20,500, how many commercial messages should be run on each medium to maximize total audience contact? Television Radio Online What is the allocation of the budget among the three media, and what is the…arrow_forwardplease check the answered and please provide me the right answers for each field. thank youarrow_forward

- You work for the Brad's Nailer Company which manufactures two types of nailers: a pneumatic model and a cordless model. You have contracted to supply a national retail chain with both pneumatic nailers and cordless nailers. However, Brad's nailer production capability is limited in three departments: production, testing, and packaging. Your answer will be the production hours needed to execute a production plan that minimizes costs - rounded to the nearest whole hour. (The number of nailers may not be a whole number, which is acceptable in this chapter.) Use Scenario 2 Pneum. Cost Pneum. Prod Hrs Pneum. Test Hrs Pneum. Pkg Hrs Pneum. Sales Cordless Cost Cordless Prod Hrs Cordless Test Hrs Cordless Pkg Hrs Cordless Sales Prod Hrs max Testing Hrs max Pkg Hrs max Scenario 1 Scenario 2 Scenario 3 52 0.2 0.3 0.1 22,000 67 0.3 0.4 0.1 15,500 10,000 15,000 4,800 55.50 0.4 0.3 0.1 24,500 69.75 0.3 0.5 0.1 15,500 20,000 18,000 4,200 38.50 0.25 0.4 0.1 18,000 44 0.4 0.4 0.2 14,000 20,000 18,000…arrow_forwardDana’s Ribbon World makes award rosettes. Following is information about the company: Variable cost per rosette $ 2.00 Sales price per rosette $ 6.00 Total fixed costs per month $ 6000.00 Required: 1. Suppose Dana’s would like to generate a profit of $1,120. Determine how many rosettes it must sell to achieve this target profit. 2. If Dana’s sells 2,140 rosettes, compute its margin of safety in units, in sales dollars, and as a percentage of sales. 3. Calculate Dana’s degree of operating leverage if it sells 2,140 rosettes. 4a. Using the degree of operating leverage, calculate the change in Dana’s profit if unit sales drop to 1,819 units. 4b. Prepare a new contribution margin income statement to verify change in dana's profit.arrow_forwardFitness Express sells three different types of elliptical machines. They have manufactured 50 of each machine for a special sale. The store already ha orders for 46 of machine A and 16 of machine B. Use the following information to determine how many of machine C the store needs to sell to break even? Show your work on a separate sheet of paper. Manufacturing Cost $105.00 $140.00 $175.00 Elliptical Machine Machine A Machine B Machine C Total costs of all machines: $ Total revenue: $ Number of machine Cs to sell to break even: Retail Cost $250.00 $305.00 $420.00arrow_forward

- Kala is one of the top manufacturer of ukuleles. The manufacturer produces three different types of ukuleles. Its Concert produce $6 in profit per unit; its Soprano produce $4 in profit per unit; and its Tenor produce $8 in profit per unit. Each type of ukulele passes through three manufacturing stages as a part of the entire production process. The three process centers of modelling, curing and assembly has an available production time per day of 12 hours, 14 hours and 16 hours, respectively. To produce one hundred units of Concert, the time required for the process of modelling, curing and assembly is 2 hours, 3 hours and 2 hours, respectively. To produce one hundred units of Soprano, 2 hours of modelling, 2 hours of curing and 1 hour of assembly is required. Whereas 4 hours of modelling, 2 hours of curing and 2 hours of assembly is required to produce one hundred units of Tenor. Sensitivity report of the problem is given as below where C = unit of Concert to be produced each day, S…arrow_forwardWhich one of the following is a variable to be considered when calculatingproduction lot size? a forecasted demandb customer orderc the lower of customer orders and forecasted demandd the higher of customer orders and forecasted demandarrow_forwardA linear programming computer package is needed. The Westchester Chamber of Commerce periodically sponsors public service seminars and programs. Currently, promotional plans are under way for this year's program. Advertising alternatives include television, radio, and online. Audience estimates, costs, and maximum media usage limitations are as shown. Constraint Television Radio Online Audience per advertisement 400,000 72,000 160,000 Cost per advertisement $2,000 $300 $600 Maximum media usage 10 20 10 To ensure a balanced use of advertising media, radio advertisements must not exceed 50% of the total number of advertisements authorized. In addition, television should account for at least 10% of the total number of advertisements authorized. If the promotional budget is limited to $20,500, By how much would audience contact increase if an extra $100 were allocated to the promotional budget? (Round your answer to the nearest whole number.)arrow_forward

- Pol Industries uses a job order cost system and applies manufacturing overhead costs to jobs using a predetermined overhead rate based on direct labour-hours. The following data were extracted from the company's accounting records for Year 6 Estimated Actual Manufacturing overhead costs 50,000 54,000 direct labour-hours 20,000 hours 24,000 hoursJob #461 was completed during the year and the following costs had been incurred on that job:direct materials 4000 direct labour 1500(at $5.00 per direct labour hour) Suppose Job #461 contained 100 units. What unit cost would appear on the job cost sheet for job #461? Show ALL calculations.arrow_forward) The following data have been prepared for master production scheduling purposes in IKEA Australia: End product A: Beginning inventory of 60, Period forecast of 10, Lot size of 30, and 30 hours in lot size. End product B: Beginning inventory of 20, Period forecast of 5, Lot size of 20, and 20 hours in lot size. End product C: Beginning inventory of 30, Period forecast of 15, Lot size of 50, and 50 hours in lot size. Capacity: 38 hours/ week (i) Prepare the master production schedule for these items during the next four periods using the Ethan Allen master production scheduling method. (ii) Suppose that the master production schedule is frozen for the next three periods. What specific impact would the policy have on the IKEA's performance?arrow_forwardSturgill Manufacturing Inc. needs to predict the numbers of machines and employees required to produce its planned production for the coming year. The plant runs three shifts continuously during the workweek, for a total of 120 hours of capacity per week. The shop efficiency (the percent of total time available for production), which accounts for setups, changeovers, and maintenance, averages 70% with a standard deviation of 5%, which reduces the weekly capacity. Six key parts are produced, and the plant has three different types of machines to produce each part. The machines are not interchangeable as they each have a specific function. The time to produce each part on each machine varies. The mean time and standard deviation (in hours) to produce each part on each machine are shown below: Mean Time Part Type Machine A Machine B Machine C 1 3.5 2.6 8.9 2 3.4 2.5 8 3 1.8 3.5 12.6 4 2.4 5.8 12.5 5 4.2 4.3 28 6…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.