Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

thumb_up100%

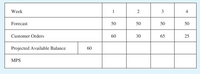

Given the following data, calculate the projected available balance and the planned

MPS receipts. The lot size is 100. The demand time fence is 2 weeks.

Transcribed Image Text:Week

1

2

3

4

Forecast

50

50

50

50

Customer Orders

60

30

65

25

Projected Available Balance

60

MPS

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Suppose we are formulating a Master Production Schedule (MPS) for an item. Week O projected on- hand is 83 units. The lot-size policy for this item calls for L4L ordering. Lead time for this item is one week. There are no safety stock requirements. Here are the demand forecast and the booked orders for this item . Week 2 3 4 5 6 Forecast 60 45 45 45 45 60 Booked 59 48 30 10 What will be the order size of the first MPS Start Quantity that is needed?arrow_forwardAssume you are the manager of a shop that assembles power tools. You have just received an order for 55 chain saws, which are to be shipped at the start of week 8. Pertinent information on the saws follows: Item Lead Time (weeks) On Hand Saw A B C D E F 2 1 2 2 1 1 2 Gross requirements Scheduled receipts Projected on hand Net requirements Planned order receipt Planned order release Ĉ E(3) & E(2) LT = 1 week Lot size: Lot-for-Lot 15 10 5 65 20 10 30 Skip Extension Tip: Double click to open in new tab Show Transcribed Text Develop the material requirements plan for component E using lot-for-lot ordering for all items. (Leave no cells blank - be certain to enter "0" wherever required.) Components A(2), B(1), C(4) E(3), D(1) D (2), F(3) E(2), D (2) Beg. Inv. 1 2 3 190 5 210 6arrow_forwardh ow is master production schedule created and how it is used ?arrow_forward

- Complete the MPS record below for a single item. (Enter your responses as integers. A response of "0" is equivalent to being not applicable.) Item: A Quantity on Hand: 80 Forecast Customer orders (booked) Projected on-hand inventory MPS quantity 1 70 40 ☐☐ January 2 70 65 80 Order Policy: 100 units Lead Time: 1 week February Week 4 40 0 5 45 35 50 70 45 0 8 50 0arrow_forwardA part is produced in lots of 1,000 units. It is assembled from2 components worth $50 total. The value added in produc-tion (for labor and variable overhead) is $60 per unit, bring-ing total costs per completed unit to $110. The average leadtime for the part is 6 weeks and annual demand is 3,800 units,based on 50 business weeks per year.a. How many units of the part are held, on average, in cycleinventory? What is the dollar value of this inventory?b. How many units of the part are held, on average, in pipe-line inventory? What is the dollar value of this inventory?(Hint: Assume that the typical part in pipeline inventoryis 50 percent completed. Thus, half the labor and variableoverhead cost has been added, bringing the unit cost to$80, or $50 + $60>2).arrow_forwardsniparrow_forward

- The Bawl Corporation supplies alloy ball bearings to automanufacturers in Detroit. Because of its specialized manu-facturing process, considerable work-in-process and rawmaterials are needed. The current inventory levels are$2,470,000 and $1,566,000, respectively. In addition, fin-ished goods inventory is $1,200,000 and sales (at cost) forthe current year are expected to be about $48 million. Ex-press total inventory asa. Weeks of supplyb. Inventory turnsarrow_forwardAssume material A calls out material B (qty per = 1). Material A has a stock quantity of 10. Material A has a demand for 100 due on 7/1 and there is an order for 90 with a due date of 7/1 and start date of 6/15. What is the requirement QUANTITY that will be generated for product B?arrow_forwardThe partially completed inventory record for the rotor subassembly in the table below shows gross requirements, scheduled receipts, lead time, and current on-hand inventory. a. Complete the last three rows of the record for an FOQ of 160 units. (Enter your responses as integers. A response of "0" is equivalent to being not applicable) Item: Rotor subassembly Gross requirements Scheduled receipts Projected on-hand inventory Planned receipts 15 1 65 160 H 2 10 3 50 4 35 Lot Size: FOQ-160 units Lead Time: 2 weeks Week 5 80 6 80 7 80 8 80 000 0000 0000arrow_forward

- You have developed the following simple product structure of items needed for your gift bag for a rush party for prospective pledges in your organization. You forecast 200 attendees. Assume that there is no inventory on ha nd of any of the items. Explode the bill of material. (Subscripts indicate the number of units required.)arrow_forwardI understand that as per the calculations, the gross requirement for week 3 is 50 (25*2) (Item A's order releases), week 5 is 190 (20*2) + (150*1) (Item A's order releases + Item B's order releases), and week 6 is 300 (150*2) (Item A's order releases). But I want to know why do we do it that way because If I have a similar question do I always multiply item A's order release for week 3 by 2, week 5 (Item A's order releases x 2 + Item B's order releases x 1), and and week 6 (Item A's order releases x 2 ) I want to understand why we do that so I can anwser a similar question I don't understand why we do that have way just that you did it that wayarrow_forwardConsider the bill of material for product P and the data given in the following table. The master schedule requirements for P are 60 units in week 6. Items Q and Rare manufactured internally by the firm and use the lot-for-lot lot-sizing rule. Item is purchased from a local distributor, and has a Fixed Order Quantity of 50 pieces per order. Use a blank matrix to solve for the MRP requirements. Q(2) S(3) R(3) Quantity on Hand 5. Scheduled reccipts Item Lead Time 15 20 in week 2 R. S. 25 15 in week 1 Given the following information, how many R's should be ordered? O 180 O 330 O 360 O 165 O 225 -/2/2arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.