Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

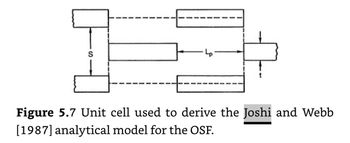

Transcribed Image Text:### Figure 5.7: Unit Cell for Derived Analytical Model

The figure illustrates a unit cell that is utilized in deriving the analytical model by Joshi and Webb (1987) for the OSF (Orthogonally Stiffened Frame).

#### Explanation:

- **Unit Cell Structure:** The diagram shows a simplified representation of a unit cell.

- **Arrows and Lines:**

- Several arrows indicate forces or directions of stress/strain within the structure.

- "S" denotes a specific parameter associated with the unit cell's structure.

- "Lp" represents another parameter, possibly related to the length or another geometric aspect of the unit cell.

### Detailed Description:

- The unit cell consists of rectangular blocks with arrows suggesting the directions of forces or connections within the framework.

- The outer rectangles are connected with dashed lines, likely indicating the boundary or the limits of the unit cell.

- The parameter "S" and "Lp" are key variables in the model being derived.

**Purpose:** This visual representation helps in understanding how the analytical model quantifies the behavior of the OSF by breaking it down into manageable units.

**Reference:** Derived from the work of Joshi and Webb from their 1987 analytical model, the unit cell serves as a foundational element for studying and modeling structural behaviors in orthogonally stiffened frames.

For more in-depth learning, refer to Joshi and Webb's original studies and subsequent elaborative content on analytical models for architectural and engineering frameworks.

Transcribed Image Text:### Application of Analytical Model for Heat Transfer and Friction Characteristics in OSF Arrays

#### Overview

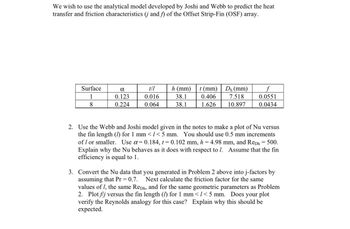

We aim to implement the analytical model developed by Joshi and Webb to predict the heat transfer and friction characteristics (denoted as **j** and **f**, respectively) of the Offset Strip-Fin (OSF) array.

#### Table 1: Surface Characteristics Data

The following table provides key parameters for two specific surface types used in the study.

| **Surface** | **α** | **t/l** | **h (mm)** | **t (mm)** | **D_h (mm)** | **f** |

|-------------|----------|---------|------------|------------|--------------|-----------|

| 1 | 0.123 | 0.016 | 38.1 | 0.406 | 7.518 | 0.0551 |

| 8 | 0.224 | 0.064 | 38.1 | 1.626 | 10.897 | 0.0434 |

#### Instructions

1. **Plotting Nu vs fin length (l):**

Use the Webb and Joshi model as specified in the course notes to create a plot of Nusselt number (Nu) versus the fin length (l) in the range of 1 mm to 5 mm, in 0.5 mm increments or smaller. For these calculations, utilize the following parameters:

- α = 0.184

- t = 0.102 mm

- h = 4.98 mm

- \(Re_{D_h}\) = 500

While plotting, explain the behavior of the Nusselt number (Nu) in relation to different lengths (l). Assume the fin efficiency to be 1.

2. **Conversion to j-factors:**

Convert the Nusselt number data from Problem 2 into j-factors, assuming \(Pr = 0.7\). Next, calculate the friction factor for the same values of fin length (l), \(Re_{D_h}\), and the geometric parameters. Plot the ratio \(f/j\) versus the fin length (l) for the range 1 mm < l < 5 mm. Evaluate the plot to verify the Reynolds analogy and discuss why the observed trends should be expected.

### Detailed Graphs and

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 6 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY