Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Please correct the answers for the attached part with step-by-step calculations:

Given information below:

Water flows at a rate of 2.4f * t ^ 3 / s in an old, rusty 7.8-in.-diameter pipe that has a relative roughness of 0.010. It is proposed that by inserting a smooth plastic liner with an inside diameter of 7.0 in. into the old pipe as shown in the Figure the pressure drop per mile can be reduced. Is it true that the lined pipe can carry the required 2.4f * t ^ 3 / s at a lower pressure drop than in the old pipe? Support your answer with appropriate calculations.

Attached Part that needs correcting.

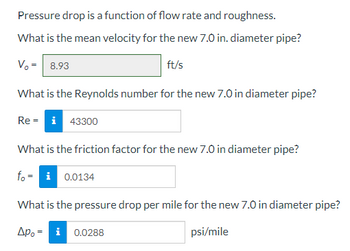

Transcribed Image Text:Pressure drop is a function of flow rate and roughness.

**What is the mean velocity for the new 7.0 in. diameter pipe?**

- \( V_0 = 8.93 \, \text{ft/s} \)

**What is the Reynolds number for the new 7.0 in diameter pipe?**

- \( \text{Re} = 43300 \)

**What is the friction factor for the new 7.0 in diameter pipe?**

- \( f_0 = 0.0134 \)

**What is the pressure drop per mile for the new 7.0 in diameter pipe?**

- \( \Delta p_0 = 0.0288 \, \text{psi/mile} \)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 8 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Please help to solve attached picture.arrow_forwardhi, please help me with all parts of this question :) thank you!arrow_forwardliquid (density 800kg/m3, viscosity 10−3 kg/ms) has to be supplied at a mean speed of 2m/s through a pipe of diameter 12.5mm with a surface roughness equivalent to that for structural steel. What is the magnitude of the pressure gradient necessary to achieve this flow? Your answer should have a positive sign and be to the nearest 10 Pa/m. You may wish to use the Moody diagram.arrow_forward

- I have attached the given moody diagram in this question, how do I complete this question accuractely?arrow_forward(2) It is desired to deliver 60 m'/hr of water at 20°C through horizontal asphalted cast iron pipe. Estimate the pipe diameter d that will cause the pressure drop to be exactly 40 kPa per 100 m of pipe length. Take water density p Solve this problem iteratively using either Moody chart or the Colebrook equation. 998 kg/m and dynamic viscosity µ = 0.001 kg/(m.s).arrow_forwardI want step by step solution.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY