Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

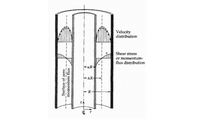

Consider the following system where the fluid is moving upward in an annulus of height L using cylindrical coordinates

Transcribed Image Text:Velocity

distribution

Shear stress

or momentum-

flux distribution

AR

Surface of zero

momentum flux

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Which of the following statement is TRUE? (A) Friction factor f in laminar flow depends on the Reynolds number and the surface roughness of the pipe (B Both Circular and non-circular pipes can withstand large pressure differences between the inside and the outside without undergoing any significant distortion. The pressure drop in a pipeline changes by a factor of 2 when the velocity of the flowing fluid is doubled (D) In a steady flow/ streamline flow, the rate of mass entering the flow system equals that leaving, as mass can neither accumulated nor depleted within a flow system under steady conditions (E) Reynolds experiment concluded that at streamline flow, thevelocity moved from a minimum at the tube center to a maximum atthe wall whereas the fluid itself moved in shells or lamina.arrow_forwardParallel laminar Flow Between Infinite Planes with a Manometer A Newtonian fluid with viscosity μf and density pf is contained between two infinite horizontal parallel planes (separated by a distance d as shown below). The fluid flows laminarly under the action of a pressure gradient and the velocity U of the upper plane (the bottom plane is fixed). A manometer (with fluid density pm and viscosity μm) is connected between two points L apart along the bottom plane and indicates a differential reading of Ah. Using the coordinate system depicted in the figure below, calculate the velocity distribution in terms of known variables by performing a shell balance. What value must U have so that the frictional drag force on the upper plate is zero? Sketch the velocity profile for this last case (i.e., zero frictional drag force on the upper plate). d Pf ༑ Ah Pm L Xarrow_forwardWater flows through a triangle tunnel. For water, the height is h and the width is w. Determine how the volumetric flowrate of water q depends on h, w and g (gravitational acceleration).arrow_forward

- In planar flow of an incompressible fluid, the x component of the velocity is given by u = ½ x² + 2x – 4y. Use the equation of continuity to derive the expression for v. %3Darrow_forward4. Consider two-dimensional, laminar, unidirectional flow between parallel (spacing: 2h), vertical plates. One plate, to the left, is moving downward with constant velocity vi; the other is moving upward at a constant velocity v2. If we consider the fluid Newtonian, solve for the velocity profile using our newly defined Navier-Stokes Eqns.arrow_forwardDetermine the pressure difference in [Pa] between points A and B for the manometer shown in Figure H.arrow_forward

- Problem 3: A model equation for chemical reactive flow in a one-dimensional reactor is given as ac ac +u. ôt dx :DOC-KC, where C is the dimensionless concentration of the species, u is the velocity, D is a diffusion coefficient, k is a reaction rate, and x,t are the distance from the reactor and time, respectively. (3a) Determine the dimensions of D, k;arrow_forwardConsider an incompressible 2D flow with stream function Y = xy + y³. Determine (a) the velocity at point (3,5). (b) the flow rate per depth for a curved segment y + x² = 4 in the second quadrant.arrow_forwardA Newtonian fluid with constant density flows in a parallel-plate apparatus that separated by a distance d and length L as shown in Figure 1. The top plate is moving in z-direction with a velocity uw. Derive the velocity distribution of the fluid, vz as a function of y using equation of motion in Appendix 1. List the postulates and you may neglect the gravity force.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The