Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

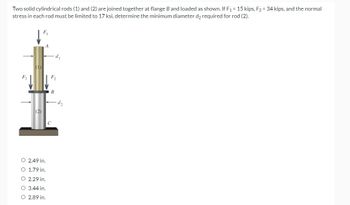

Transcribed Image Text:Two solid cylindrical rods (1) and (2) are joined together at flange B and loaded as shown. If F₁ = 15 kips, F₂ = 34 kips, and the normal

stress in each rod must be limited to 17 ksi, determine the minimum diameter d₂ required for rod (2).

F₁

(1)

(2)

A

O 2.49 in.

O 1.79 in.

O 2.29 in.

O 3.44 in.

O 2.89 in.

d₁

F₂

B

C

d₂

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A rigid bar AB of length L = 1600 mm is hinged to a support at A and supported by two vertical wires attached at points C and D such that AC = 500mm and AD = 1200mm Both the wires have same cross sectional area of 16 mm² and made of the same material having Young's modulus of 200 GPa. The wire at C has a length of 400 mm and that at D has 800 mm. Determine the tensile stresses in the wires and downward displacement at point B of the bar when a load of 1 kN is suspended at B.arrow_forwardRigid bar ABC is supported by a pin at bracket A and by tie rod (1). Tie rod (1) has a diameter of 8 mm, and it is supported by double- shear pin connections at B and D. The pin at bracket A is a single-shear connection. The pin at B is 5 mm in diameter. Assume a = 570 mm, b = 285 mm, h = 360 mm, and 0= 65°. If the normal stress in tie rod (1) cannot exceed 190 MPa and the shear stress in pin B cannot exceed 120 MPa, determine the maximum load Pmax that can be supported by the structure. D (1) h B a Answer: Pmax i b kNarrow_forwardTwo solid cylindrical rods (1) and (2) are joined together at flange B and loaded as shown. If F₁ = 13 kips, F₂ = 34 kips, and the normal stress in each rod must be limited to 22 ksi, determine the minimum diameter d₁ required for rod (1). A (2) d₁ F₂ B C O 1.087 in. O 0.823 in. O 0.541 in. O 0.867 in. O 1.003 in. d₂arrow_forward

- Members BC and DE are 50 mm wide and 16 mm thick and made of steel (E = 200 GPa). Member AF is rigid. For a load of P = 60 kN, determine 500 mm (a) the normal stress in member BC, В C (b) the normal stress in member DE, 250 mm E (c) the displacement of point A. D Assume BC and DE do not yield or buckle. 250 mm F 500 mm- 650 mmarrow_forwardTwo aluminum plates, each having a width of b = 8.0 in. and a thickness of t = 0.750 in., are welded together as shown. Assume a = 4.0 in. For a load of P = 75 kips, determine (a) the normal stress that acts perpendicular to the weld and (b) the magnitude of the shear stress that acts parallel to the weld. Answer: O= P T = 1 i 1 ksi ksi b Parrow_forwardA 10-mm diameter steel bolt is surrounded by bronze sleeve. The outer diameter of the bronze sleeve is 20 mm and its inner diameter is 10-mm. Given that the yield stress for the steel is 640 MPa and the yield stress for the bronze is 520 MPa, determine the magnitude of the maximum allowable total load that can be applied to this assembly. (Assume full bond between the steel and the bronze sleeve) Esteel = 200 GPa, Ebronze = 100 GPa, Factor of safety = 1.5arrow_forward

- 2. A 6 mm diameter pin is used in connection C of the pedal shown. Knowing that P = 500 N. Determine: 1. The average shear stress in the pin. 2. The average crushing effort in the pedal C. 3. The crushing stress in the supports of C. The figure is in the attached imagearrow_forward1200 N 2. For the bone shown to the left, assume the cross-section at C can be approximated as annular, with an outer diameter of 25mm. When the 1200 N forces are applied, the average normal stress in the bone at point C is determined to be 3.80 MPa. Determine the inner diameter of the bone cross section at C. Ans: d; = 14.93 mm 4 in. P 3 in. B 1200 N "UI 8arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY