Materials Science And Engineering Properties

1st Edition

ISBN: 9781111988609

Author: Charles Gilmore

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

10

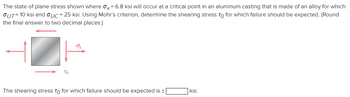

Transcribed Image Text:The state of plane stress shown where x = 6.8 ksi will occur at a critical point in an aluminum casting that is made of an alloy for which

OUT=10 ksi and σUC= 25 ksi. Using Mohr's criterion, determine the shearing stress To for which failure should be expected. (Round

the final answer to two decimal places.)

The shearing stress To for which failure should be expected is ±[

ksi.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- Compare the engineering and true secant elastic moduli for the natural rubber in Example Problem 6.2 at an engineering strain of 6.0. Assume that the deformation is all elastic.arrow_forwardA steel with E = 29 000 ksi with a rectangular cross-section is bent over a rigid mandrel with R = 15 in as shown in the figure. If the maximum flexural stress in the bar is not to exceed the yield strength of 36 ksi, determine the allowable thickness h of the bar.arrow_forwardA steel component is subjected to alternate cyclical loading. The steel follows Basquin's law for high cycle fatigue, o, x N = C, (where the stress amplitude is in MPa). Ignore the geometric detail and assume that Marin's modifying factors are all equal to 1. You are given the minimum stress ain = -213 MPa, the maximum stress omax = 213 MPa. The material data are Tensile strength oUTS = 539 MPa, Basquin's constant c, = 875 MPa, Basquin's exponent a = 0.085. a) Calculate the stress ratio R, the stress amplitude o, in MPa and the mean stress am in MPa. The answers are acceptable with a tolerance of 0.01 for R and of 1 MPa the stresses. R: MPa MPа b) Calculate the corresponding life, in 10° cycles, (tolerance of 0.1 106 cycles) N :arrow_forward

- As shown, an aluminium alloy construction BCD with a circular cross section is fixed at end B and affected by a force of 150 N at the free end D. The diameter of the cross-section a-a is 20 mm. The yield strength of the material is 80 MPa: a) Determine the stresses at point A of the a-a cross-section. As indicated in the picture, draw the stress element in Cartesian coordinates and specify the stress values.(b) Calculate the factor of safety, n for Tresca, and the von Mises yield criterion to see if the structure would yield based on the stresses at point A.(c) In the major stress area, draw the yield loci of both criteria and indicate the operational stress state & why is the Rankine failure criterion inappropriate for aluminium alloys?arrow_forward3. The distribution of stress in an aluminum machine component is given (in megapascals) by Ox = y + z? Oy = x + z Oz = 3x + y Txy = 3z2 Tyz = x Txz = %3D Calculate the state of strain at a point positioned at (1,2,4). Use E=70 GPa and v = 0.3arrow_forwardSITUATION. As shown in the figure below, a rigid bar with negligible mass is pinned at O and attached to two vertical rods. Assume that the rods were initially stress-free. Allowable stress in steel is 120 MPa and in bronze is 60 MPa. For this problem, a = 1.8m; b = 1.3m; c= 1.7m. a b I Steel: A 900 mm Bronze: A E 200 GPa E 83 GPa L-2.0m L=1.5m What is the value of P without exceeding the allowable stress of steel, in KN? 230 250 280 340 1200 mmarrow_forward

- Problem 1 An aluminum rod is rigidly attached between a steel rod and a bronze rod as shown. Axial loads are applied at the positions indicated. Aluminum Steel A=800mm2 A=1000mm2 Bronze A=700mm? 4P 2P 500mm 600mm 700mm 1. What is the maximum value of P that will not exceed the axial stress bronze of 105 MPa? 2. What is the maximum value of P that will not exceed the axial stress in aluminum of 90 MPa? 3. If P=10KN, what is the axial force to be carried by the aluminum in KN? 4. If P is 5KN, what is the axial stress of steel?arrow_forwardSITUATION. As shown in the figure below, a rigid bar with negligible mass is pinned at O and attached to two vertical rods. Assume that the rods were initially stress-free. Allowable stress in steel is 120 MPa and in bronze is 60 MPa. For this problem, a = 1.8m; b = 1.3m; c= 1.7m. a b C P Steel: A-900 mm² Bronze: A=1200 mm² E = 83 GPa L=2.0 m E = 200 GPa L=1.5m What is the value of P without exceeding the allowable stress of bronze, in kN? O 161 O 174 O 145 124 4arrow_forwardAn aluminum alloy [E = 67 GPa; ν = 0.33; α = 23.0 × 10–6/°C] plate is subjected to a tensile load P. The plate has a depth of d = 225 mm, a cross-sectional area of A = 5100 mm2, and a length of L = 4.1 m. The initial longitudinal normal strain in the plate is zero. After load P is applied and the temperature of the plate has been increased by ΔT = 63°C, the longitudinal normal strain in the plate is found to be 2900 με. Determine: (a) the magnitude of load P. (b) the change in plate depth Δd.arrow_forward

- An aluminum alloy [E = 73 GPa; v = 0.33; a= 23.0 x 10-6/°C] plate is subjected to a tensile load P. The plate has a depth of d = 250 mm, a cross-sectional area of A = 6900 mm², and a length of L = 5.9 m. The initial longitudinal normal strain in the plate is zero. After load P is applied and the temperature of the plate has been increased by AT = 50°C, the longitudinal normal strain in the plate is found to be 2400 με. Determine: (a) the magnitude of load P. (b) the change in plate depth Ad. L Answer: (a) P = i (b) Δd = KN mmarrow_forwardAn aluminum rod is rigidly attached between a steel rod and a bronze rod as shown below. Axial loads are applied at the positions indicated. Find the maximum value of P in Newton that will not exceed a stress in steel of 150 MPa, in aluminum of 87 MPa, or in bronze of 97 MPa.arrow_forwardAxial Load, P(kN) A 2 m long axially loaded mild steel rod of 8 mm diameter exhibits the load-displacement (P -8) behavior as shown in the figure. 14000 12000 10000 8000 6000 4000 2000 0 1 2 7 8 9 10 3 4 5 6 Displacement 8(mm) Assume the yield stress of steel as 250 MPa. The complementary strain energy (in N-mm) stored in the bar up to its linear elastic behavior will bearrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning