Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

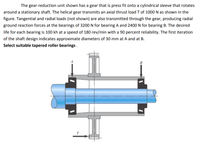

Transcribed Image Text:The gear-reduction unit shown has a gear that is press fit onto a cylindrical sleeve that rotates

around a stationary shaft. The helical gear transmits an axial thrust load T of 1000 N as shown in the

figure. Tangential and radial loads (not shown) are also transmitted through the gear, producing radial

ground reaction forces at the bearings of 3200 N for bearing A and 2400 N for bearing B. The desired

life for each bearing is 100 kh at a speed of 180 rev/min with a 90 percent reliability. The first iteration

of the shaft design indicates approximate diameters of 30 mm at A and at B.

Select suitable tapered roller bearings.

B

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Q8/ An epicyclic reduction gear shown in figure, has a shaft A fixed to arm. The arm has a pin fixed to its outer end and two gears C and E which are rigidly fixed (C-E compound gear) revolve on this pin. Gear C meshes with annular gear D and gear E with pinion F. G is the driver gear and D is kept stationary. The number of the teeth is as follows: Tp = 80, Tc =10, TE = 24 and Tp = 10. The gear G runs at 200 rpm, find the speed of shaft A. (Area ge Darrow_forward3. A flat annular steel flywheel of outer radius 0.5 m and inner radius 0.125 m with p = 7800 kN*s?/m* and v = 0.3 is to be shrunk fit around a solid steel shaft. The shrinking allowance is 0.1 mm. Both materials are the same type of steel with E = 210 GPa. Determine the RPM when the shrink fit loosens as a result of rotation.arrow_forwardplease help solvearrow_forward

- Assume that the gear keyed to the shaft shown in the figure below is a Class 50, cast iron flywheel of 15-inin outside diameter and 1-in thickness. The hub is 4-in dia and 3-in thick. The shaft is steel. Determine the critical frequency of shaft whirl for the assembly shown using the following dimensions: a = 4 in , b = 12 in , l = 14 in , the shaft diameter is 2 in. Assume the following: The applied transverse force PP and the Torque TT to be zero. The mass of the steel shaft can be ignored.arrow_forwardProblem 3arrow_forwardGear shaft ABCDE is subjected to the torques shown in the figure. Find the internal torque in each seg- ment, and then plot the torsional moment diagram. Assume that the spacing between gears is constant, i.e., 10 in. T1 = T2 = 1000 lb-in. 500 lb-in. A B T3 = 800 Ib-in. C Ta = 500 lb-in. d = 1.0 in. D T; = 800 lb-in. Earrow_forward

- hello please help me this homework question considering the time limit I have less than 30minarrow_forwardA gear drive is required to transmit a maximum power of 22.5KW, the velocity ratio is 1:2 and the rpm of the pinion is 200 .the approximate center distance between the shaft may be taken as 600mm.the teeth has 20°stub involute profile.the static stress for the gear material ( which is cast iron ) may be taken as 60MPa and face width as 10 times the module.find the module, face width and number of teeth on each gear.Check the design for dynamic and wear loads. The deformation factor in the buckling equation may be taken as 80 and material combination factor for the wear as 1.4arrow_forwardsolve, show all steps for given solution.arrow_forward

- Solve correctly please.arrow_forwardIn a gear set, a 36-tooth spur pinion drives a 60-tooth spur gear. The teeth of these gear are cast iron profile. The diametral pitch is 6-teeth/in, the face width si 0.5 inches, and the pressure angle is 20 degrees. Assume that the pinion transmits 10 hp at a speed of 2000 rpm. Find the tangential load in lbf Find the contact stress in kpsi, assuming CP=1960 psi.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY