Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

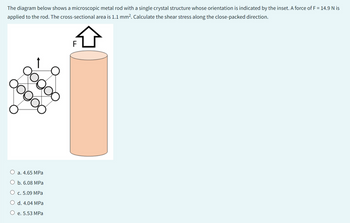

Transcribed Image Text:The diagram below shows a microscopic metal rod with a single crystal structure whose orientation is indicated by the inset. A force of F = 14.9 N is

applied to the rod. The cross-sectional area is 1.1 mm². Calculate the shear stress along the close-packed direction.

Dogo

ooooo

a. 4.65 MPa

O b. 6.08 MPa

c. 5.09 MPa

O d. 4.04 MPa

O e. 5.53 MPa

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A brass rod is 3 m long at temperature of 15oC. Find the expansion of the rod, when the temperature is raised to 50oC. If this expansion is prevented, find the stress induced in the material of the rod. You will need to research suitable values for α and Earrow_forwardA composite section 2 m in length, consisting of a steel tube with outer diameter 24 mm and thickness 3 mm, encloses a solid copper bar 18 mm diameter. An axial compressive load of 250 KN is applied on the assembly. Young’s modulus for steel and copper are taken as 2 x 105 N/mm2and 1 x 105N/mm2respectively. Calculate the stresses developed in steel and copper. Also calculate the load taken by both the materials.arrow_forwardProblem 2. A block of cast iron was wrapped in the thin aluminum foil as shown on the figure. At room temperature there is no stress on the foil. The whole system is then immersed in liquid nitrogen at -196°C. Find the stress on the aluminum foil. Is the foil going to deform permanently? Is it going to break? Stress [MPa] 350 300 250 200 150 100 50 0 0 alu alloy 5083-H34 0.005 0.01 0.015 0.02 Strain Aluminum foil 5 µm thick, this is a continuous strip with the ends welded together Cast iron 20 mm thick a aluminum = 2.4 105 K-¹, Stress MPa 400 300 200 100 a iron 1.2 105 K-1 ↑ 11 0 0 0.05 0.1 0.15 0.2 0.25 Strain Fig. 2. Stress-strain diagrams for aluminum. Left: Low strain region. Right: Full strain range. Hint: you can get the Young's modulus, proportions limit (elastic limit), and break point from the graphs.arrow_forward

- (c) An element is subject to the stresses shown below in Figure 5 Calculate the centre and radius of the Mohr's stress circle and sketch the circle (1) (ii) Calculate the values of principal stresses and show them on the circle (ii) Determine the direction of the larger principal stress relative to the 75 N/mm. 30 N/mm A 14 Nmm 75 N/mm2 30 N/mm Figure 5arrow_forwardThe diagram below shows a microscopic metal rod with a single crystal structure whose orientation is indicated by the inset. A force of F = 28.4 N is applied to the rod. The cross-sectional area is 0.6 mm². Calculate the shear stress along the close-packed direction. ooog OOOO a. O b. 21.26 MPa O c. 14.11 MPa O d. 19.32 MPa O e. 17.78 MPa 16.23 MPaarrow_forwardThe diameter (d) of a solid rod (i.e., with a circular cross-section) is 16 mm and is made from a homogeneous material. The length (L) of the rod is 1.75 m and Young’s Modulus for the material (E) is 250 GPa. When the rod is placed under tension it experiences deformation and a stress (?) of 650 MPa. Calculate the following:(1) Strain energy (U) to 2 decimal places in Joules.(2) Strain energy per unit volume (U/V) in J/m3(3) The change in length ∆L to 2 decimal places in mm.(4) The strain (?) due to deformation to 2 significant figures. (show all work)arrow_forward

- A dislocation is anchored between two points 10 μm distant. For a metalwith b = 0.35 nm and G = 30 GPa, compute the shear stress necessary tobow the dislocation into a semicircle.arrow_forwardRigid bar ABCD is loaded and supported as shown. Steel [E = 29800 ksi] bars (1) and (2) are unstressed before the load P is applied. Bar (1) has a cross-sectional area of 0.86 in.² and bar (2) has a cross-sectional area of 0.47 in.2. After load P is applied, the strain in bar (1) is found to be 780 μe. Assume L₁-52 in., L₂=74 in., a=20 in., b=25 in., and c-33 in. Determine: (a) the stresses in bars (1) and (2). (b) the vertical deflection vp of point D on the rigid bar. (c) the load P. Answers: (a) σ1 (b) VD=i (c) P = i L eTextbook and Media Save for Later (1) B L2 b (2) ksi, 0₂ = in. kips. i D P ksi. Attempts: 0 of 5 used Submit Answerarrow_forwardThe diagram below shows a microscopic metal rod with a single crystal structure whose orientation is indicated by the inset. A force of F = 25.8 N is applied to the rod. The cross-sectional area is 1.9 mm². Calculate the shear stress along the close-packed direction. O a. 5.10 MPa O b. 6.10 MPa c. 4.66 MPa O d. 5.54 MPa Oe. 4.05 MPaarrow_forward

- Consider a metal rod with a critical resolved shear stress of 40 MPa for a specific crystallographic plane (hkl). The angle between the normal to the plane and the applied force is 30 degrees, and the angle between the slip direction and the force is 15 degrees. Two force levels of F1 = 75 N and F2 = 40 N is applied. The cross-sectional area of the rod is 1 mm^(2). Will the slip initiate at the two force levels? Select one: a. F1: Yes, F2: No b. F1: No, F2: No OC. F1: Yes, F2: Yes Od. F1: No, F2: Yesarrow_forwardFigure 2.1. shows two long plates with same material and equal width w=20 mm that are subjected to a uniaxial tensile load o. One of the plates has a single small central hole with diameter 4mm and another plate has two small holes with a distance of 8mm from each other. The holes are perpendicular to the external tensile load. Develop a computer code (or simulation model) and analyze how stresses will be distributed at the tip of the holes in these two plates for different values of 0. 4mm Figure 2.1. 8mm 4mmarrow_forwardI need a clear answer by hand, not by keyboard and fast answer within 20 minutes. Thank you | dybalaarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY