Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

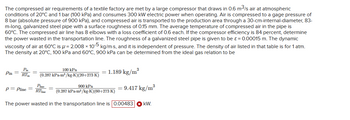

Transcribed Image Text:The compressed air requirements of a textile factory are met by a large compressor that draws in 0.6 m³/s air at atmospheric

conditions of 20°C and 1 bar (100 kPa) and consumes 300 kW electric power when operating. Air is compressed to a gage pressure of

8 bar (absolute pressure of 900 kPa), and compressed air is transported to the production area through a 30-cm-internal-diameter, 83-

m-long, galvanized steel pipe with a surface roughness of 0.15 mm. The average temperature of compressed air in the pipe is

60°C. The compressed air line has 8 elbows with a loss coefficient of 0.6 each. If the compressor efficiency is 84 percent, determine

the power wasted in the transportation line. The roughness of a galvanized steel pipe is given to be ε = 0.00015 m. The dynamic

viscosity of air at 60°C is μ = 2.008 × 10-5 kg/m-s, and it is independent of pressure. The density of air listed in that table is for 1 atm.

The density at 20°C, 100 kPa and 60°C, 900 kPa can be determined from the ideal gas relation to be

Pin =

Pin

RT

100 kPa

(0.287 kPa-m³/kg-K)(20+273 K)

P= Pline =

= 1.189 kg/m³

Pline

900 kPa

RTline (0.287 kPa-m³/kg-K)(60+273 K)

The power wasted in the transportation line is 0.00483 kW.

= 9.417 kg/m³

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Question 3.3 When the air with a pressure of 0.1 MPa and a specific volume of 0.8 m³/kg was provided into a compressor at a flow rate of 0.25 kg/s, its pressure became 0.7 MPa and its specific volume became 0.2 m³/kg. Through the compression, the specific internal energy was increased by 80 kJ/kg, and there was heat loss of 50 kJ/s to the environment. In this case, calculate the work [k]/s = kW] that the compressor did in unit time. Potential energy and kinetic energy can be negligible.arrow_forwardWater at 50°F is pumped from a lake at 750 gpm through a length of 3-inch schedule 40 commercial steel pipe as shown below. The inlet to the pipe is eight feet below the surface of the lake. A 25-HP gasoline engine drives the pump and the pump has an efficiency of 80% What is the Reynolds number in the pipe? Is the flow laminar or turbulent? What is the head added to the water by the pump? What is the head loss due to pipe friction?arrow_forwardHello, I have an equalization tank with the following dimensions: Height: 5.15 meters Length: 10.3 meters Width: 30.48 meters Total volume calculated: 1616.8116 m³ How can I calculate the air requirement for the tank? The flow rate is 2.5 MGD.arrow_forward

- A certain jet fuel has a kinematic viscosity of 1.2 x 10-6 m2/s. If the fuel is being delivered to the engine at 200 L/min through a steel tube (Diameter = 22.10 mm), compute the Reynold number and identify the type of flow either laminar or turbulent?arrow_forwardA constant-area duct that is 20 cm in length by 2 cm in diameter is connected to a reservoir through a converging nozzle, as shown in Figure 9.13. For a reservoir pressure and tem- perature of 1 MPa and 500 K, determine the maximum air flow rate in kilograms per sec- ond through the system and the range of back pressures over which this flow is realized. Repeat these calculations for a converging nozzle with no duct. Assume that fis equal to 0.032 and that y - 1.4. f= 0.032 D-2 cm Isentropic flow P1,000 kPa I 500 K 20 cmarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning