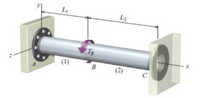

The aluminum alloy [G = 4000 ksi] pipe is fixed to the wall support at C. The bolt holes in the flange at A were supposed to align with mating holes in the wall support; however, an angular misaligment of 4° was found to exist. To connect the pipe to its supports, a temporary installation torque T'B must be applied to B to align flange A with the mating holes in the wall support. The outside diameter of the pipe is 5.5625 in. and its wall thickness is 0.258 in. The segment lengths are L1= 16 ft and L2 = 24 ft.

a) Determine the temportary installation torque T'B that must be applied to B to align the bolt holes at A

b) Determine the maximum shear stress τinitial in the pipe after the bolts are connected and the temporary installation torque at B removed

c)Determine the magnitude of the maximum shear stress in segment (1) and (2) if an external torque TB= 150 kip-in. is applied at B after the bolts are connected

Trending nowThis is a popular solution!

Step by stepSolved in 7 steps with 1 images

- The shaft shown in the figure is machined from AISI 1040 CD steel. The shaft rotates at 1600 rpm and is supported in rolling bearings at A and B. The applied forces are F₁ = 1600 lbf and F2 = 640 lbf. A steady torque of 1600 lbf-in is being transmitted through the shaft between the points of application of the forces. 1 / in ] A in [lin -10 in- F₁ in F₂ -10 in- All fillets in R. 12in] 3 in The value of the notch sensitivity is The value of the fatigue stress concentration factor is in NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. What is the value of the theoretical stress concentration factor for torsion, the notch sensitivity, and the fatigue stress concentration factor? (You must provide an answer before moving to the next part.) The value of the theoretical stress concentration factor for torsion isarrow_forwardWhat is the over-turning moment at x = 0, of a hollow tube that has an OD of 40 mm, and an ID of 20 mm. The length of the tube is 960 mm. It is attached to a 1 inch thick plate.arrow_forwardPlease and thankarrow_forward

- I am struggling with this questionarrow_forwardPlease don't give an incorrect solution. Important problem, Include the FBD.arrow_forwardTorque in = 40nm Holding torque out = 896nm 8.Using your answers from the gear box above, and given that the input shaft has a diameter of 12 mm and the output shaft has a diameter of 15 mm, both shafts are made from aluminium. When this transmission system was operated, it failed. Identify the position where the failure occurred and the reason for this failure. Suggests improvements to the system to overcome the failure mode. The shear strength of aluminium is 207 MPa.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY