Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Suppose that the motion of the adjustable roller has a damping coefficient b, and that the force

exerted by the rolled material on the adjustable roller is proportional to the material's change in

thickness: f=c(T-x). Suppose further that the DC motor has a torque constant K, and a back-

emf constant Ke, and that the rack-and-pinion has effective radius of r. In reality the thickness of

the input material. T. is one of the inputs. but here for simplicitv assume T is constant. Do not

neglect the weight of the adjustable roller and assume mg = cT.

The input of the system is the voltage of DC-motor and the output is the thickness of the

output material ,x.

1. Draw free body diagram of adjustable roller

2. Prepare a mathematical block diagram showing mathematical relations in terms of the transfer

functions. The block diagram should at least contains a block for DC-motor and a block for

mechanical system (i.e gears and adjustable rollers)

3. Determine transfer function G(s)=X(s)/Vs(s)

4. After finding the transfer function in part 3, assume the armature inductance of the DC.

motor is negligible (L = 0), assume zero initial conditions and determine the output x(t) as

a function of time if the input voltage vs (t) is an unit step. Express the result in terms of the

appropriate system parameters: i.e. damping ratio and undamped natural frequency.

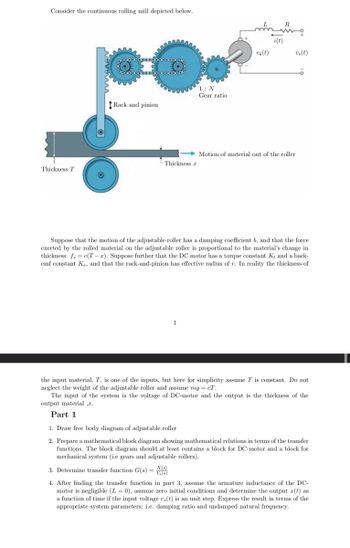

Transcribed Image Text:Consider the continuous rolling mill depicted below.

Thickness T

00000

Rack and pinion

Ö

Thickness a

1: N

Gear ratio

1

en(t)

i(t)

vs(t)

Motion of material out of the roller

6

Suppose that the motion of the adjustable roller has a damping coefficient b, and that the force

exerted by the rolled material on the adjustable roller is proportional to the material's change in

thickness: fs = c(T-a). Suppose further that the DC motor has a torque constant K, and a back-

emf constant Ke, and that the rack-and-pinion has effective radius of r. In reality the thickness of

the input material, T, is one of the inputs, but here for simplicity assume T is constant. Do not

neglect the weight of the adjustable roller and assume mg = cT.

The input of the system is the voltage of DC-motor and the output is the thickness of the

output material ,.

Part 1

1. Draw free body diagram of adjustable roller

2. Prepare a mathematical block diagram showing mathematical relations in terms of the transfer

functions. The block diagram should at least contains a block for DC-motor and a block for

mechanical system (i.e gears and adjustable rollers).

3. Determine transfer function G(s) = X(6)

4. After finding the transfer function in part 3, assume the armature inductance of the DC-

motor is negligible (L= 0), assume zero initial conditions and determine the output z(t) as

a function of time if the input voltage v, (t) is an unit step. Express the result in terms of the

appropriate system parameters: i.e. damping ratio and undamped natural frequency.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Two identical thin bars, each of mass m and length L, are welded together at a right angle as shown in figure 1. This T-shaped assembly is pinned to ground at point 0. Block B is given a prescribed forced displacement xg = b sin øt. Friction and damping are neglected. a) Derive the equation of motion for the system in terms of the angular position of the bars, 6, and parameters m, L, k, and g; b) Derive an expression for the natural frequency of the system; c) Derive an expression for the forced angular response of the system; L/2 L/2 L Хвarrow_forwardrevision help past paper answer neededarrow_forwardSolvearrow_forward

- Q4\Find the type of damping in this system Where: m=5kg, K = 1500 /m N Damping coefficient= 1.5 *105 N-sec/marrow_forwardThe figure below shows a single degree of freedom control surface/actuator system. The control surface has a mass moment of inertia J = 30 kg.m2 about the hinge, the effective actuator stiffness and damping values are k = 3000 N/m and c = 500 Ns/m respectively and the rotation of the control surface is rad. The actuator lever arm has length a = 0.2 m. A force f (t) = 58 (t) N is applied to the control surface at a distance d = 1 m from the hinge. It is assumed that the main surface of the wing is fixed rigidly as shown in the figure. Assume small angle approximation. Determine the tip velocity (velocity at the location of f(t)) at t = 0.1 s 0(t) f(t) C 152.74 mm/s 499.47 mm/s 583.77 mm/s 400.63 mm/s 285.64 mm/s darrow_forward4. Problem 2: Consider the block diagram shown in the figure below. Determine the values of K and k such that the system has a damping ratio & = 0.7 and an undamped natural frequency wn = 4 rad/s. Please, use the block diagram algebra and the secondarrow_forward

- For a single degree of system mass is 20kg stiffness=6.25kN/m damping coefficient 20Ns/m.Initial displacement at t=0 is zero and initial velocity is 150m/s obtain the equation of motion and find the displacement at 2secondsarrow_forwardQuestion 2: a. Determine the differential equation of motion and find the natural frequency (w). Also establish the critical damping for the system shown in Fig. 2a b. If the system has a mass of 0.907 kg with spring stiffness of 7.0 N/cm. Determine the critical damping coefficient.arrow_forwardThe equation of motion of a certain mass-spring-damper system is 5x'' + cx' +10x = f(t). Suppose that f(t) = Fsin(wt). Define the magnitude ratio as M = X/F. Determine the natural frequency w_n, the peak frequency w_p, and the peak magnitude ratio M_p for damping ratio = 0.1 and the damping ratio = 0.3arrow_forward

- A mass of 5kg on a spring with k=5N/m and damping constantly=6Ns/m. Using forcing function cos(ωt), find the value of ω that causes practical resonance.arrow_forwardThe quarter-car model of a vehicle suspension and its free body diagram are shown in Figure 1. In this simplified model, the masses of the wheel, tire, and axle are neglected, and the mass m represents one-fourth of the vehicle mass. The spring constant k models the elasticity of both the tire and the suspension spring. The damping constant c models the shock absorber. The equilibrium position of m when y=0 is x=0. The road surface displacement y(t) can be derived from the road surface profile and the car’s speed. Draw free body diagram (FBD) and derive the equation of motion of m with y(t) as the input, and obtain the transfer function. If assume: m=300 kg k=20000, 40000, 60000 N/m c=1000, 3000, 5000 N.s/m Plot magnification ratio vs frequency ratio (r=0-4) diagrams for the parameters given above (you can draw the three curves in one diagram for three different k values and do the same for the three c values as well). Use the derived transfer function to model the system and plot…arrow_forwarda lot of people say this is the answer but some say it is not , please check for mearrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY