Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Determine the absolute shear stress for point K.

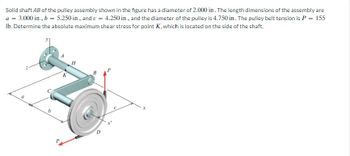

Transcribed Image Text:Solid shaft AB of the pulley assembly shown in the figure has a diameter of 2.000 in. The length dimensions of the assembly are

a = 3.000 in., b = 5.250 in., and c = 4.250 in, and the diameter of the pulley is 4.750 in. The pulley belt tension is P

= 155

Ib. Determine the absolute maximum shear stress for point K, which is located on the side of the shaft.

a

b

K

H

x

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Using transformation equations of plane stress, determine the normal and shear stress components for X’-axis located 0.5 radians clockwise from x-axis. The non-zero stress components are given as follows, σx= 200 MPa, σy= 100 MPa, τxy= -50 MPa.arrow_forward1. Find the average normal stress. 2. Find the maximum in-plane shear stress.arrow_forwardIf M=2.5kip.ft, determine the magnitute of the resultant force the bending stresses produce on the top board A of the beam.arrow_forward

- What steps should be taken to obtain The resultant internal loadings at a point located on the section of a body using the method of sections?arrow_forwardThe main stress, the maximum shear stress, and the dead angle are obtained when the stress is given as shown in the picture below.Draw Mohr's circle.arrow_forwardThe state of stress at a point on an element of material is shown. Let sigmaX= 49.0 ksi, sigmaY= 17.0 ksi, and Txy= 11.0 ksi. Use this information to represent the principle state of stress and maximum in plane shear stress. Plot the mohr circle and state sigmaX' and sigmaY' and Tx'y' with unit. Also draw the state of stress on the rotated element.arrow_forward

- Determine state of stress at the remaining points (P2, P3 and P4). Calculate the maximumprincipal (σ1) and maximum in-plane stress (τmax) for the remaining points (P2, P3 and P4) located at Point A.arrow_forwardThe 3/4-in.-diameter shaft is subjected to the loading shown. Determine the stress components at point A. Sketch the results on a volume element located at this point. The journal bearing at C can exert only force components Cyand Cz on the shaft, and the thrust bearing at D can exert force components Dx, Dy, and Dz on the shaft.arrow_forwardFor the shaft shown below, determine the normal and shear stresses acting on the element located at point A, including stress concentrations. Then draw the stress element at A with the applied stresses and determine the three principal stress (0₁, 2 and, σ3) using Mohr's circle. r = 0.0042 m, d = 0.03 m, D = 0.033 m, T = 250 Nm P = 1500 N, M = 300 Nm, A M M DEHRƏC T d T P P rarrow_forward

- Determine the state of stress at point q. The pipe has an inner diameter of D₁ = 1.0 in and an outer diameter of = 1.8 in. Use the exact expression for Q, if needed. Label the reultant forces on the cross section below. Report your answer (3x3 matrix) in psi to one decimal place. Do 4 in. Y 4 in. 150 lb 6 in. 50 lb 10 in. 200 lb 150 lb X N Yarrow_forwardThe 0.97 in diameter rod is subjected to the loads shown. Determine the normal and shear stress at point B.arrow_forwardFor the stresses given with the cube below: 1. Compute the center, radius (R), principal normal stresses (0₁ and 03), max shear stress (Tmax) and draw the Mohr's Circle. 2. Compute the normal and shear stresses when the cube is rotated 20° clockwise from the horizontal plane and draw them on the cube. 3. The yield point stress (σyp) is 6 kPa. Determine if the material will fail under stresses shown using Tresca's Hexagon. вкра акра 6 экра 8 кра экра 4краarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY