Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Need answers asap thank you

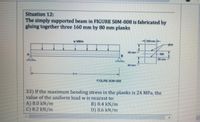

Transcribed Image Text:Situation 12:

The simply supported beam in FIGURE SOM-008 is fabricated by

gluing together three 160 mm by 80 mm planks

w kN/m

160mm

due

80 mm

NA

80 mm

80 mm

FIGURE SOM-008

33) If the maximum bending stress in the planks is 24 MPa, the

value of the uniform load w is nearest to:

A) 8.0 kN/m

C) 8.2 kN/m

B) 8.4 kN/m

D) 8.6 kN/m

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- LESSON: AUTODESK AUTOCAD Choose from the choices:arrow_forwardI need answer within 20 minutes please please with my best wishesarrow_forwardb. ENGT 2020 -Robotic Fundamentals Lab 3.5 Creating a Program 1. What are the four types of moves and describe how they move between waypoints. a. C.arrow_forward

- Thank you for your great effort but please i need solution by hand written and number of table at step by step thank youarrow_forwardPaula has worked for Brindle Corporation for 3 years. During this time, she has worked as a machine operator/cell leader in various work cells. Recently, the plant went to mandatory 12-hour shifts and plans to remain on this schedule for several months. Paula’s present work cell is manufacturing 3-inch diameter exhaust tubes that are made from stainless steel. These tubes get a hole punched in them, a flange welded on, and burrs ground off. The pipe then gets placed into a gage to check that it was made correctly. (The tubes weigh about six pounds.) Paula has been performing the welding operation. She leans into the machine and loads the part into a fixture then positions the flange. Both pieces are clamped (using hand clamps) into position and the machine is cycled by depressing two palm buttons. The gaging operation requires placing the finished part into the gage and clamping it (using hand clamps) into place. A pin is depressed to verify the position of the hole and a…arrow_forwardThe SMART technique for problem solving was introduced. In this approach, S stands forarrow_forward

- Paula has worked for Brindle Corporation for 3 years. During this time, she has worked as a machine operator/cell leader in various work cells. Recently, the plant went to mandatory 12-hour shifts and plans to remain on this schedule for several months. Paula’s present work cell is manufacturing 3-inch diameter exhaust tubes that are made from stainless steel. These tubes get a hole punched in them, a flange welded on, and burrs ground off. The pipe then gets placed into a gage to check that it was made correctly. (The tubes weigh about six pounds.) Paula has been performing the welding operation. She leans into the machine and loads the part into a fixture then positions the flange. Both pieces are clamped (using hand clamps) into position and the machine is cycled by depressing two palm buttons. The gaging operation requires placing the finished part into the gage and clamping it (using hand clamps) into place. A pin is depressed to verify the position of the hole and a…arrow_forwardDon't need to show work, just need to know which ones correct to compare my answers. 9.10.arrow_forwardSummary/Conclusion Discuss the strengths of your design and how it met the specifications. Discuss your assumptions and why they are valid. Discuss what you might change about your design in a redesign effort. Format: The project should be presented as a design report using a word processor. Include any hand calculations in an appendix. More details will be provided. Choose to design either a slip-jaw or channel-lock pliers to last for 25 years of use by a professional. Use an appropriate tool steel for the pliers. Design for 95% male grip force. Use a minimum factory of safety of 2.50. Determine dimensions not given. Slip Jaw Pliers A= 9.00 inches B=1.00 inches C= ? D=1.25 inches H= 1.875 Inches D B Aarrow_forward

- Hi, can I please have some ideas of what sort of questions you would ask about this project? (The poster seen is meant as a review of what topic was picked and where the project is up to after a few weeks.)arrow_forwardPlease solve it complete please don't copy pastearrow_forwarduse this logo and explain for safteyarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY