Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

-

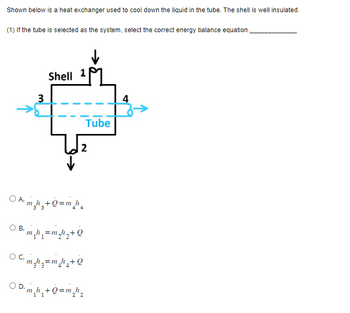

Shown below is a heat exchanger used to cool down the liquid in the tube. The shell is well insulated.

(1) If the tube is selected as the system, select the correct energy balance equation._____________

A. B. C. D.

Transcribed Image Text:**Heat Exchanger System Analysis**

This image depicts a heat exchanger utilized for cooling the liquid flowing through a tube. The system ensures that the surrounding shell remains well insulated.

**Diagram Details:**

The diagram shows a shell and tube configuration with the following flow paths:

- Inlet (1) into the shell and outlet (2) from the shell for the cooling medium

- Inlet (3) into the tube and outlet (4) from the tube for the liquid being cooled

Flow is directed with arrows, indicating the liquid's movement from the inlet to the outlet within the tube system. The primary objective is to transfer heat from the liquid in the tube to the surrounding shell.

**Question for Analysis:**

1. When considering the tube as the system, identify the correct energy balance equation.

**Options for the Energy Balance Equation:**

- **A.** \( \dot{m}_3 h_3 + \dot{Q} = \dot{m}_4 h_4 \)

- **B.** \( \dot{m}_1 h_1 = \dot{m}_2 h_2 + \dot{Q} \)

- **C.** \( \dot{m}_3 h_3 = \dot{m}_4 h_4 + \dot{Q} \)

- **D.** \( \dot{m}_1 h_1 + \dot{Q} = \dot{m}_2 h_2 \)

In these equations, \(\dot{m}\) denotes mass flow rate, \(h\) represents specific enthalpy at respective inlets and outlets, and \(\dot{Q}\) indicates the rate of heat transfer.

The correct energy balance equation must account for the conservation of energy within the tube, considering mass flow rates and corresponding changes in specific enthalpy.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- all questions please thank you so mucharrow_forwardQ1) A heat exchanger is to be designed to heat 32/68 mixture of ethylene glycol and water from 24 ᵒC to 55 ᵒC by a hot water stream from 79 ᵒC to 42 ᵒC. Flow rate of cold stream is 20 kg/s. Inlet pressure for both stream is 50 psi and the maximum pressure drop of 10 psi for cold stream and 8 psi for hot water are permissible. Report valid assumptions made for the design and give required justification. Estimate Heat Transfer, Corrected LMTD, Tube bundle diameter (Using TEMA standards and Codes) and Tube cross sectional area Heat transfer coefficient Overall heat transfer coefficient Pressure Drop (Shell side & Tube Side)arrow_forwardThe clean U for an exchanger is 800 BTU/(hr 0 F ft2). Its tube area is 600 ft2. After operating for several months heating water from 50 0F to 160 0F at a flow rate of 210 GPM with a heating fluid on the shell entering at 290 0F and exiting at 160 0 F has the overall U decreased significantly?arrow_forward

- The food storage room requires a cooling system with a capacity of 10 tons of refrigeration which operates at an evaporator temperature of -17.8 degrees Celsius and a condenser temperature of 30.1 degrees Celsius. The activities used are R-717 and the operating system is in saturated conditions. Determine a. Flow rate b. refrigerant flow rate c. rate of heat loss in the condenser.arrow_forwardWhat are the 3 major thermal resistances to heat flow in a double -pipe heat exchanger. State assumptions.arrow_forwardin a 10-m long center-current flow tubular heat exchanger, a liquid food, flowing in the inner pipe (inside diameter 5 cm), is heated from 4 to 60 C for pasteurization. In the outer tube (diameter 10 cm), hot water enters at 95 C and exits at 80 C. A) If the mass flow rate of the hot water is 5 kg/s, what is the flow rate of the pasteurized product? The specific heat of the water is 4.2 kJ/(kg C), specific heat of product is 3.8 kJ/(kg C) B) what is the log mean temperature difference C) What is the overall heat transfer coefficient for the heat exchanger based on the outside surface?arrow_forward

- QUESTION 9 As in the previous question, a concentric-tube, counter-flow heat exchanger, as shown below, is used to cool mercury [C, h = 1,370 J/kg - "C] flowing at a rate of 1.0 kg/s from 110°C to 70°C. 10 The cooling fluid is water entering the heat exchanger at a temperature of 30°C and flow rate of 0.2 kg/s. The overall heat transfer coefficient of the exchanger is U = 250 w/m² - °C. Water Mercury Calculate the required heat transfer area. O 7.75 m2 O 11.75 m2 O 4.75 m2 O None of these answers O 8.75 m2 Click Save and Submit to save and submit. Click Sare All Answers to save all answers. Save All Answers 人 100% Garrow_forward3.36 Both C's in a parallel-flow heat exchanger are equal to 156 W/K, U 327 W/m²K and A = 2 m². The hot fluid enters at 140°C and leaves at 90°C. The cold fluid enters at 40°C. If both C's are halved, what will be the exit temperature of the hot fluid?arrow_forwardUsing that information and this table For the average monthly rate of geothermal heat available, determine, for the real case: in a tabular format and show sample calculation for one month. the necessary monthly average mass flow rate (in kg/s) of the refrigerant that must be pumped through the heat exchanger to collect the thermal energy from the available geothermal hot water flow rate if the hot water was cooled by 5°C. What should be the flow capacity (in kg/s) of feed pump of the ORC heat engine that you are designing and the monthly average net electric power generation capacity (in kW). 2. the monthly average net electric power generation capacity (in kW) and yearly average net electrical power generation capacity (in kW).arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY