College Physics

11th Edition

ISBN: 9781305952300

Author: Raymond A. Serway, Chris Vuille

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:**Title: Understanding the Role of Sherifs in E-Beam Lithography**

**Introduction:**

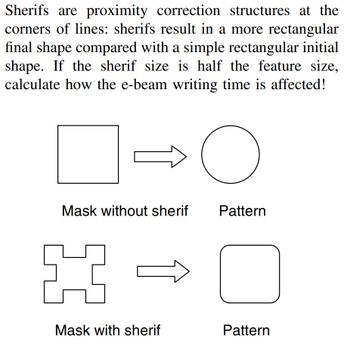

Sherifs are proximity correction structures used at the corners of lines in e-beam lithography. Their primary function is to enhance the final shape of the patterned area, making it more rectangular compared to a simple rectangular initial shape. This adjustment is crucial for achieving precise and desired outcomes in microfabrication processes.

**Explanation of Concepts:**

- **Sherifs**: These are small structures added to mask designs to correct distortions that occur during the patterning process.

- **Proximity Correction**: A technique intended to compensate for the undesired spreading of the electron beam during writing, which can cause features to deviate from their intended shapes.

**Impact on E-Beam Writing Time:**

When integrating sherifs, if the size is half the feature size, there must be a calculation on how this change affects the e-beam writing time. Typically, these adjustments may lead to increased exposure times due to the added complexity in the pattern structure.

**Diagrams and Their Significance:**

1. **Mask without Sherif:**

- **Illustration**: A simple square moves into a circular pattern.

- **Interpretation**: This transformation shows what typically happens when no proximity correction is applied; the intended shape becomes distorted (rounding of corners).

2. **Mask with Sherif:**

- **Illustration**: A square with extended corners (sherifs) moves into a more precise rectangular pattern.

- **Interpretation**: Highlighting the effectiveness of sherifs, this transformation demonstrates how the original mask design with sherifs helps maintain the intended rectangular shape after exposure.

**Conclusion:**

Incorporating sherifs in mask design for e-beam lithography is essential for minute precision in pattern making. By understanding and applying these proximity correction structures, engineers can ensure more accurate and reliable microfabrication outcomes.

Expert Solution

arrow_forward

Step 1

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, physics and related others by exploring similar questions and additional content below.Similar questions

- The prcimany of a branfoumere har to lwns Poo uolt and loo nall: Find the and uoike mumbee of luins in Seconday to step up vollage to 400vy deo calculte the auent in Suonday t frimary:arrow_forwardWhich of the following would be NOT be a density independent limiting factor .arrow_forwardUpload a PDF document that shows your work and solution. The Sun has a luminosity of L = 3.846 × 1026 W, and a radius of Rs = 697,000 km. Working with R² L = the inverse-square law for intensities, Io R² and the surface-intensity of the Sun as I TTR 1 how much power would a 12.0 m² solar panel collect on Earth as compared to that when used on a ? Take the distance from the Sun to PJupiter PEarth Galilean moon of Jupiter - in short, what is the ratio Earth as RE = 1.49 x 10⁹ m and from the Sun to a Galiena moon as RJ = 7.78 x 10⁹ m, and the power formula is P= I. A where I is the intensity of light at a given distance from the Sun, and A is the area of the solar panel.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

College PhysicsPhysicsISBN:9781305952300Author:Raymond A. Serway, Chris VuillePublisher:Cengage Learning

College PhysicsPhysicsISBN:9781305952300Author:Raymond A. Serway, Chris VuillePublisher:Cengage Learning University Physics (14th Edition)PhysicsISBN:9780133969290Author:Hugh D. Young, Roger A. FreedmanPublisher:PEARSON

University Physics (14th Edition)PhysicsISBN:9780133969290Author:Hugh D. Young, Roger A. FreedmanPublisher:PEARSON Introduction To Quantum MechanicsPhysicsISBN:9781107189638Author:Griffiths, David J., Schroeter, Darrell F.Publisher:Cambridge University Press

Introduction To Quantum MechanicsPhysicsISBN:9781107189638Author:Griffiths, David J., Schroeter, Darrell F.Publisher:Cambridge University Press Physics for Scientists and EngineersPhysicsISBN:9781337553278Author:Raymond A. Serway, John W. JewettPublisher:Cengage Learning

Physics for Scientists and EngineersPhysicsISBN:9781337553278Author:Raymond A. Serway, John W. JewettPublisher:Cengage Learning Lecture- Tutorials for Introductory AstronomyPhysicsISBN:9780321820464Author:Edward E. Prather, Tim P. Slater, Jeff P. Adams, Gina BrissendenPublisher:Addison-Wesley

Lecture- Tutorials for Introductory AstronomyPhysicsISBN:9780321820464Author:Edward E. Prather, Tim P. Slater, Jeff P. Adams, Gina BrissendenPublisher:Addison-Wesley College Physics: A Strategic Approach (4th Editio...PhysicsISBN:9780134609034Author:Randall D. Knight (Professor Emeritus), Brian Jones, Stuart FieldPublisher:PEARSON

College Physics: A Strategic Approach (4th Editio...PhysicsISBN:9780134609034Author:Randall D. Knight (Professor Emeritus), Brian Jones, Stuart FieldPublisher:PEARSON

College Physics

Physics

ISBN:9781305952300

Author:Raymond A. Serway, Chris Vuille

Publisher:Cengage Learning

University Physics (14th Edition)

Physics

ISBN:9780133969290

Author:Hugh D. Young, Roger A. Freedman

Publisher:PEARSON

Introduction To Quantum Mechanics

Physics

ISBN:9781107189638

Author:Griffiths, David J., Schroeter, Darrell F.

Publisher:Cambridge University Press

Physics for Scientists and Engineers

Physics

ISBN:9781337553278

Author:Raymond A. Serway, John W. Jewett

Publisher:Cengage Learning

Lecture- Tutorials for Introductory Astronomy

Physics

ISBN:9780321820464

Author:Edward E. Prather, Tim P. Slater, Jeff P. Adams, Gina Brissenden

Publisher:Addison-Wesley

College Physics: A Strategic Approach (4th Editio...

Physics

ISBN:9780134609034

Author:Randall D. Knight (Professor Emeritus), Brian Jones, Stuart Field

Publisher:PEARSON