Fundamentals Of Construction Estimating

4th Edition

ISBN: 9781337399395

Author: Pratt, David J.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

V7

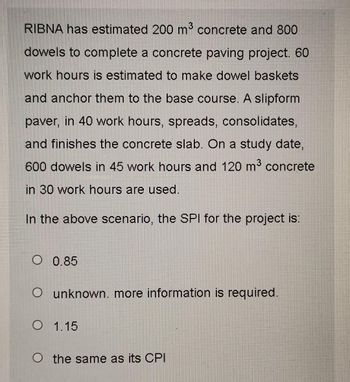

Transcribed Image Text:RIBNA has estimated 200 m³ concrete and 800

dowels to complete a concrete paving project. 60

work hours is estimated to make dowel baskets

and anchor them to the base course. A slipform

paver, in 40 work hours, spreads, consolidates,

and finishes the concrete slab. On a study date,

600 dowels in 45 work hours and 120 m³ concrete

in 30 work hours are used.

In the above scenario, the SPI for the project is:

O 0.85

O unknown. more information is required.

O 1.15

O the same as its CPI

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Calculate total cost per cubic yard of concrete, given the following: Concrete materials and batching costs = $70/cy Trucking = $6.00/cy Paving equipment = $340.00/hr - Paving labor = $500.00/hr Paver production = 120 cy/hr Incidentals $4.00/cy Overhead and profit = 20% of direct costs 1.87.0 = O2.106.8 O 3.104.4 4.99.6arrow_forwardCalculate total cost per cubic yard of concrete, given the following:Concrete materials and batching costs = $70/cyTrucking = $6.00/cyPaving equipment = $370.00/hrPaving labor = $530.00/hrPaver production = 120 cy/hrIncidentals = $4.00/cyOverhead and profit = 20% of direct costs Group of answer choices $100.20 $87.5 $105.00 $107.50arrow_forwardCalculate the cost per cubic yard to place concrete using each of the alternatives described. The work in both cases consists of placing 140 cubic yards of concrete in footings. a. Using a crane and bucket at a price of $225 per hour, including an operator, with a crew consisting of 6 laborers, a cement finisher, and a foreman. The concrete will be placed in 7 hours using this setup, and transportation of the crane costs $390. b. Using a concrete pump at a price of $295 per hour, including an operator and a crew consisting of 5 laborers, a cement finisher, and a foreman. With this setup, concrete is placed in 6 hours and transportation of the pump costs $290.arrow_forward

- Hi, I need this asap pls. Thank you so much.arrow_forwardA cement grinding mill "A" with a capacity of 50 tons per hour employs P12,000 per tonforged steel grinding balls with a wear rate of 100 grams per ton of cement processed.Another cement mill of the same capacity, "B," utilizes P50,000 per ton high chromesteel grinding balls with a wear rate of 20 grams per ton of cement processed.Determine the more cost-effective grinding mill, keeping all other factors constant. do not use excel, use formulaarrow_forwardYou are given the following information about a dry-batchpaving operation. You are going to use one mixer that has aservice rate of 30 services per hour. The dry-batch trucksyou use for bringing concrete to the paver have an arrivalrate of 7.5 arrivals per hour. Each truck carries 6 cubic yardsof concrete. You have a total amount of 13,500 cubic yardsof concrete to pour. You rent a truck at $15 per hour and thepaver at $60 per hour. If the job takes more than 80 hours,you pay a penalty of $140 per hour owing to delays in jobcompletion. On the basis of least cost, determine the numberof trucks you should use. Plot the cost versus the numberof trucks used.arrow_forward

- A Highway contractor has four locations A, B, C, and D on a road contract to which crushed stone is to be delivered. The stone, which is all of the same quality is to be supplied from two quarries 1 and 2. The table below shows the relative transportation cost per cubic meter of transporting stone from each quarry to each site. Quarry 12 2 A 9 12 45 Location B с D Relative transportation costs ($ per m³) 15 10 8 105 Quantities required at each location (m³) 11 3 135 6 150 Quarry output (m³) 120 255 a) What is the optimal allocation of the crushed stone from each quarry to each location? b) What is the transportation cost corresponding to the solution obtained in part a?arrow_forward5. Using the concrete price quotation shown on Figure 11.2, calculate the full price of 4000 psi concrete with type I colored cement, 1/2" aggregate, and air entrainment to be delivered to the site in December: (10 pts) ABC CONCRETE PRODUCTS, INC. PROJECT: XYZ Office Bulding. Townvle. We are pleased to quote you as follows for the supply of ready-mix delivered to the above project: Aggregate Size Delivered Price Additional for Type III or Type V Additional for 4-6% Alr Mix Strength (psi) Cement Type per CY Entrainment $120.00 $135.00 $140.00 5150.00 $155.00 $5.00 $5.50 $6.50 $7.00 $7.50 3000 3500 3/4 3/4 $4.00 $6.00 $7.00 $7.50 $8.00 1. 2. 4000 4500 3. 3/4 3/4 5. 5000 3/4" The above prices are based on ABC Concrete's standard mix designs. All products are subject to a municipal sales tax of 7%. For 1/2" aggregates add 56.50 per CY to the above prices. For polypropylene fibers add $17.00 for 2 lbs. per CY. For pigments (red, black, tan, or brown) add $5.50 per CY. Calclum Chlorlde (1%):…arrow_forwardHomework # 2 Problem 1 The labor and material cost for a riprapping work is as follows: Labor: Materials: (For every 1 cu. m. volume) 1 Foreman @ P500.00 per hour Cement = 3 bags @ P150.00 per bag 1 Skilled Worker @ p40.00 per hour Sand = 0.25 cu. m. @P300.00 per cu. m. 5 Unskilled Workers @ P35.00 per hour Boulder = 1 cu. m. @P250.00 per cu. m. The accomplishment of the above laborers is 0.45 cubic meter per hour. Profit, overhead and miscellaneous expenses is 30% of the labor and material cost. Value Added Tax (VAT) is 10% of the labor cost. a) Determine the labor cost per cubic meter. b) Determine the cost of materials per cubic meter. c) Give the total cost of riprapping per cubic meter.arrow_forward

- QUESTION 3. The construction of a reinforced concrete wall involves placing 660 m³ concrete, fixing 50 ton of steel, and 790 m² of formwork. The following information belongs to the jobs involved in this activity: * A 6-man concrete crew can place 16 m' of concrete/day. * A steel-fixer and assistant can fix 0.5 ton of reinforcement/day. * A carpenter and assistant can fix and remove 16 m² of shuttering/day. Calculate the duration of the activity considering the steel-fixer as the critical resourcearrow_forwardFrom the following figure, solve for the quantity of cement, sand and gravel by Volume method using (a) class "A" concrete; (b) Class B concrete.arrow_forwardCalculate a m3 Rate for Concrete to Beams using Readymix and a Subcontractor to place (Please see data below) BOQ item: 25MPa (1:2:4)- 19mm stone reinforced concrete in Beams…m3. Data Readymix R1250 /m3 Waste 5% Dumper with 350lt (0.35m3) skip hired at R 1600/8hr & trip 300m one way and travels @15km/hr. Fuel for dumper 30lt/day @R20/lt Readymix Offloading distance 300m one way and load in 2 minutes, unload in 2mins, maneuver for 1.5mins and travels @15km/hr Lubrication and maintenance 15% on fuel for all plant Dumper Driver @ R70/Hr Subcontractor places concrete at R 120/m3 and has an Output of 6m3/Hrarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage,

Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage,

Fundamentals Of Construction Estimating

Civil Engineering

ISBN:9781337399395

Author:Pratt, David J.

Publisher:Cengage,