Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

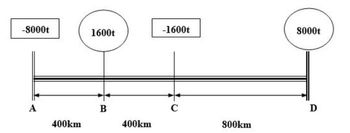

Question

A logistics company plans to provide coal logistics transportation services to HY coal sales enterprise. HY coal sales enterprise has coal storage and sales points in B and D, with available coal quantities of 1600t and 8000t, respectively; A and C represents the locations of two coal users, with a demand of 8000t and 1600t respectively. The distribution of relevant locations and travel distances are shown in Figure 1. Based on the above conditions, try to calculate and explain from the perspective of transportation capacity consumption: How should logistics company HY plan transportation routes in order to make them more reasonable? (a transportation route planning scheme needs to be illustrated) .

Note:The solution should not be hand written.

Transcribed Image Text:-8000t

A

400km

1600t

B

400km

-1600t

C

800km

8000t

D

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 7 images

Knowledge Booster

Similar questions

- 1. Huawei decided to expand in Africa. Three possible factory sites are available: Nairobi, Cape Town, and Accra. Factory building costs and transport costs to major customer zones from each site are given below. Production Cost/unit 60 Factory Site Building Cost (per million unit capacity) Cape Town Nairobi Accra 560,000 75 340,000 45 310,000 Customer Zone Demand/yr Transport Costs/unit Cape Town Nairobi Accra #1 # 2 18 million 12 15 million #3 7 9 million 26 million 16 #4 22 Huawei has a building budget of 40 million USD next year. Huawei does not wish annual logistics costs to exceed 40% of total production costs. Write a model that decides which factories will be built in what capacity while meeting annual demand and minimizing all costs. USE PARAMETERS BELOW! Parameters: TRC(ij): transport cost; D(j): demand for zone j; B(i): building cost per million capacity for site i; pr(i): production cost for site i Variables: Model:arrow_forwardThe following table gives the map coordinates and the shipping loads for a set of cities that we wish to connect through a central hub. Using the Center of Gravity method, near which map coordinates should the hub be located? STORE LOCATION CONTAINERS SHIPPED PER MONTH X Y Chicago 2,000 50 120 Pittsburgh 1,000 110 100 New York 3,000 160 130 Atlanta 2,000 120 40arrow_forwardWiebe Trucking, Inc., is planning a new warehouse to serve the western United States. Denver, Santa Fe, and Salt Lake City are under consideration. For each location, annual fixed costs (rent, equipment, and insurance) and average variable costs per shipment (labor, transportation, and utilities) are listed in the following table. Sales projections range from 550,000 to 600,000 shipments per year. Location Annual fixed cost Variable Costs per Shipment Denver $5,000,000 $4.65 Santa Fe $4,200,000 $6.25 Salt Lake City $3,500,000 $7.25 a. Plot the total cost curves for all the locations on a single graph. b. Which city provides the lowest overall costs? Thank you!!!arrow_forward

- 7. The BD restaurant chain purchases materials from four different food suppliers. The company wants to construct a new central distribution center to process and package the materials before shipping them to their various restaurants. The suppliers transport items in 40-foot truck trailers, each with a capacity of 38,000 lbs. The locations of the four suppliers and the annual number of trailer loads that will be transported to the distribution center are shown in the following table (distance in miles). Using the center-of-gravity method, determine a possible location for the distribution center. A B с D X Y 200 200 100 500 250 600 500 300 Load 75 105 135 60 BD wants to evaluate three different sites it has identified for its new distribution center relative to the four suppliers identified. The coordinates of the three sites under consideration are as follows: Site 1: x1 = 360, y₁ = 180 Site 2: X2 = 420, y2 = 450 Site 3: X3 = 250, y3 = 400arrow_forwardAn elite logistics company want to determine the optimum assignment of its fleet of trucks to deliveryroutes. The objective is to minimize total costs. The costsdata in hundreds of dollars for the various truck-routecombinations are given in the following table. Develop anassignment that will minimize total cost.Route (in U.S. dollars)Truck 1 2 3 4A 9 13 8 5B 10 11 7 6C 12 6 14 9D 8 9 10 12arrow_forwardlike this fill the boxesarrow_forward

- Assignment Find the initial solution of the given transportation problem using the 3 methods. Suppose a manufacturing company owns three factories (sources) and distribute his products to five different retail agencies (destinations). The following table shows the capacities of the three factories, the quantity of products required by the various retail agencies and the cost of shipping one unit of the product from each of the three factories to each of the five retail agencies. Factories 1 1 2 1 9 24 12 14 33 Requirement 100 60 2 3 Retail Agency 3 13 16 1 50 4 5 35 50 20 1 23 26 50 40 Capacity 50 100 150 300 ✓arrow_forward(2) Find an optimal solution for the following transportation problem. Town To Valley FROM Madison (M) Yonkers (1) Pittsburgh (P) Demand FROM Madison (M) Yonkers Pittsburgh FROM 3.50 Madison (M) Yonkers FROM $8 350 Madison (M) Yonkers (1) Pittsburgh $5 SIS 350 Valley (5) $8 $5 $15 Using the Stepping-Stone method to find an optimal plan. Tol Valley Town Junction (7) $8 Pittsburgh Demand 350 Part (a) Find the new TC= $5 $15 50 350 The above feasible plan is obtained by applying the Northwest Corner Rule (e.g., 300 from M to V, etc.), and its total cost = 350($8) +50($10)+150($12) +250($4)+200($11) +250($14) = $11.800, 150 $8 200 $5 The improvement indices below are determined as follows: Supply row M first, then sows Y and P) MJ: 9-4+12-10-2 400 MB: 6-11+12-10=-3 rv: 5-12+10-8-5 600 PP: 15-14+11-12-10-8-2 PT: 6-14+11-12- PA 11-14+11-4-4 Demand 350 200 the "most negative index" We focus on cell PT (index=-9). Its closed path is: PT to PB to YB to YT, and back to PT. To increase the…arrow_forwardConsider the transportation problem having the following data: Destination: Source 1 2 3 Demand 1 3 324 3 Unit Cost (S) 2 743 3 3 839 6 2 4 2 5 2 Supply 523 2 3 a. Draw the network representation of this problem. b. Display the problem on a spreadsheet and then use the Excel Solver to obtain an optimal solution.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.