Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

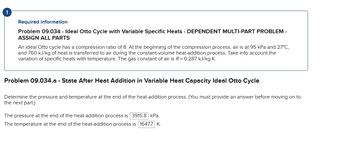

Transcribed Image Text:### Required Information

**Problem 09.034 - Ideal Otto Cycle with Variable Specific Heats - DEPENDENT MULTI-PART PROBLEM - ASSIGN ALL PARTS**

An ideal Otto cycle has a compression ratio of 8. At the beginning of the compression process, air is at 95 kPa and 27°C, and 760 kJ/kg of heat is transferred to air during the constant-volume heat-addition process. Take into account the variation of specific heats with temperature. The gas constant of air is \(R = 0.287 \, \text{kJ/kg} \cdot \text{K}\).

---

### Problem 09.034.a - State After Heat Addition in Variable Heat Capacity Ideal Otto Cycle

Determine the pressure and temperature at the end of the heat-addition process. (You must provide an answer before moving on to the next part.)

- The pressure at the end of the heat-addition process is **3915.8 kPa**.

- The temperature at the end of the heat-addition process is **1647.7 K**.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The compression ratio of an Otto cycle as shown in the figure below is VA/VB = 9.00. At the beginning A of the compression process, 505 cm3 of gas is at 115 kPa and 20.0°C. At the beginning of the adiabatic expansion, the temperature is TC = 725°C. Model the working fluid as an ideal gas with ? = 1.40.arrow_forwardAn air standard Otto cycle at the start of the isentropic compression has P₁ = 100 kPa and T₁ = 27°C. The compression ratio is 10 and during the heat addition process 1000 kJ/kg are supplied. Using the cold air standard analysis method, the net work for this cycle is most nearly equal to: A. 960 kJ/kg B. 900 kJ/kg C. 602 kJ/kg D. 333 kJ/kg E. Cannot be determined with the given informationarrow_forwardConsider a Diesel cycle with cold-air-standard assumptions, and compression ratio of 21. The temperature and pressure at the beginning of the compression process are 320K and 120kPa respectively. The cutoff ratio for this cycle is 1.8. The isentropic efficiency of the compression and expansion process are 85%. Determine the temperature and pressure at the end of each process of the cycle, the heat transfer per unit mass in and out of the air; qin and qout, thermal efficiency of the cycle, and the mean effective pressure of the cycle.arrow_forward

- ! Required information Consider an ideal gas-turbine cycle with two stages of compression and two stages of expansion. The pressure ratio across each stage of the compressor and turbine is 3. The air enters each stage of the compressor at 300 K and each stage of the turbine at 1200 K. Use variable specific heats. Determine the back work ratio and the thermal efficiency of the cycle, assuming a regenerator with 79 percent effectiveness is used. The back work ratio is The thermal efficiency is [ %. 1%.arrow_forward16-16M Consider an air-standard Otto cycle that has a compression ratio of 8.3 and a heat addition of 1456 kJ/kg of air. If the pressure and temperature at the beginning of the compression process are 0.95 bar and 7°C, determine (a) the maximum pressure and temperature for the cycle, (b) the thermal efficiency, and (c) the mean effective pressure, on the basis of Table A-SM. 16 11 nir standarrow_forwardHello Sir,Good Night.I have a question in my homework related thermodynamics lesson.The following below is my question. Please advice, thank youarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY