Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Correct solution will be liked. Thank you!!!

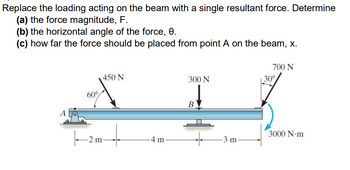

Transcribed Image Text:Replace the loading acting on the beam with a single resultant force. Determine

(a) the force magnitude, F.

(b) the horizontal angle of the force, 0.

(c) how far the force should be placed from point A on the beam, x.

A

60°

450 N

||—2m-

-4 m

300 N

B

-3 m-

700 N

30°

3000 N-m

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 6 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 04 05 a Explain the reasons for the following: 1- The pure aluminum and the copper are generally rated as easy to machine 2- In ultrasonic machining, the stress produced by the impact of abrasive particles on the workpiece surface is high. 3- In rolling process, the coefficient of friction must be sufficient. 4- Difference in solidification between casting and welding processes. 5- Why is it desirable to use energy sources for welding that have high heat densities? 6- Why there might be a change in the density of a forged product as compared to that of the cast blank. D. A cylindrical workpart with D=2.5 in and h=2.5 in is upset forged in an open die to a height = 1.5 in. Coefficient of friction at the die -work interface = 0.10 The work material has a flow curve defined by: K= 40,000 lb/in' and n-0.15. Determine the instantaneous force in the operation (a) just as the yield point is reached (yield at strain = 0.002), (b) at height = 2.3 in. (c) h= 1.9 in, and (d) h = 1.5 in. a List…arrow_forwardIf you were manufacturing a precision component which has a mass of around 15 grams and which was a solid 3D shape, which method would be appropriate?arrow_forward2) A washer is going to be manufactured by cutting operation out of 2024ST aluminum alloy sheet that has a thickness of 2.5 mm. The outside diameter of the washer is 25.0 mm, and the inside diameter is 12.0 mm. Make a rough sketch, define the geometries to be used and determine a. The punch and die size for the blanking operation b. The punch and die size for the punching operation c. The force required performing the blanking and punching operation simultaneously. The aluminum has a tensile strength = 300 MPa.arrow_forward

- what type of grinding wheel should be used to get the required finish on this part using a surface grinder?arrow_forwardSolution 1: Ergonomic Assessment and Improvement. An ergonomic assessment of Paula's workstation could identify areas where adjustments could be made to reduce strain on her wrists. This could include adjusting the height of the workstation, providing wrist supports, or changing the design of the tools she uses. The strength of this solution is that it directly addresses the physical strain causing Paula's discomfort. However, the weakness is that it may require investment in new equipment or tools, and the effectiveness will depend on the specific changes made. Solution 2: Job Rotation. Paula could be rotated between different tasks more frequently, reducing the amount of time she spends on tasks that strain her wrists. This could also include training other workers to perform the welding and gaging operations, allowing for more flexibility in task assignments. The strength of this solution is that it reduces the repetitive strain on Paula's wrists. The weakness is that it requires…arrow_forwardCan you please explain how to find the velocity using the methods described? And also why it's done that way? This is from Introduction to robotics mecahnics and controls. Please help ;( !arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY