Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

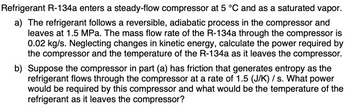

Transcribed Image Text:Refrigerant R-134a enters a steady-flow compressor at 5 °C and as a saturated vapor.

a) The refrigerant follows a reversible, adiabatic process in the compressor and

leaves at 1.5 MPa. The mass flow rate of the R-134a through the compressor is

0.02 kg/s. Neglecting changes in kinetic energy, calculate the power required by

the compressor and the temperature of the R-134a as it leaves the compressor.

b) Suppose the compressor in part (a) has friction that generates entropy as the

refrigerant flows through the compressor at a rate of 1.5 (J/K) /s. What power

would be required by this compressor and what would be the temperature of the

refrigerant as it leaves the compressor?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 13 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 2) A Refrigerant 134a at 1 MPa and 12 °C is mixed with another stream at 1 MPa and 60 °C. If the mass flow rate of the cold stream is twice that of the hot one, determine the temperature of the exit stream.arrow_forward3.9 m3/s of saturated water vapor enters a compressor at 250 kPa and leaves it with a pressure equal to 1400 kPa. Assume the process to be isentropic. Determine the work rate necessary to the nearest kW.arrow_forwardThermodynamics Question: Refrigerant – 134a is to be cooled by water in a condenser. The refrigerant enters the insulated condenser with a mass flow rate of 6 kg/min at 1 MPa, 70 oC and leaves at 35 oC. The cooling water (compressed liquid) enters at 300 kPa and 15 oC and leaves at 25 oC. Neglecting any pressure drops, kinetic and potential energy changes in the pipes, determine (a) the mass flow rate of the cooling water required and (b) the heat transfer rate from the refrigerant to water.arrow_forward

- I. Steam flows steadily into a turbine with a mass flow rate of 20 kg/s at 6 MPa and 600°C with a velocity of 120 m/s. The steam exits the turbine at 0.5 MPa and 200°C with a negligible velocity. Determine the power produced by the turbine and the work done per unit mass.arrow_forwardAir at 293 K and 100 kPa is accelerated by being sent to the nozzle after being compressed to 500 kPa in a compressor with a mechanical efficiency of 85%. The pressure at the nozzle outlet is measured as 100 kPa. Considering that the air exhibits an ideal gas behavior, the heat capacity is constant, the nozzle operates adiabatically and reversibly, and that the velocity at its inlet is negligible: a) The temperature at the compressor outlet (K) andb) Calculate the velocity (m / s) at the nozzle outlet. (Cphava = 1.005 kJ / kg.K)arrow_forwardSteam enters a turbine with a mass flow rate of 15 kg/s at 500°C and 8 MPa. 30% of the steam is removed in the middle of the turbine where the steam is at saturated vapor state at 300 kPa. The remainder of the steam leaves turbine exit at 10 kPa and quality of 10 percent. If the turbine is adiabatic, what is the power generated by this turbine?arrow_forward

- Air at a rate of 50 m3/min enters an adiabatic compressor at a pressure of 100 kPa and a temperature of 24.3 C and exits at 500 kPa and 189.55 C. It then enters an insulated heat exchanger where it gets cooled by water. The air exits the heat exchanger at a temperature of 57.35 C. Water enters the heat exchanger at 20 C and exits at 50 C. Calculate the compressor power in kW, the mass for rate of the cooling water in kg/sec, and the rate of entropy generation for the compressor and the heat exchanger. Assume a mean heat capacity of water at ?? = 4.18 ??/???. You may also assume that there is no pressure drop in the heat exchanger)arrow_forwardA compressor performs 200 hp of shaft work to compress 0.2 kg/sec of steam from saturated vapor at 147degC to state 2 with P2, T2 = 2 MPa and 357degC. The compressor is NON-adiabatic so it is also transferring heat to the surroundings in the process. Determine the heat transfer rate from the compressor. You can assume the changes in velocity and height of the system are negligible.arrow_forwardOne mole of carbon dioxide is to be compressed adiabatically from 1 bar and 25⁰C to 10 bar. Because of irreversibilities and poor design of the compressor, the compressor work required is found to be 25 % greater than that in a well-designed (reversible) compressor. Compute the outlet temperature of the carbon dioxide and the work that must be supplied to the compressor for both the reversible and irreversible compressors. Assume carbon dioxide is an ideal gas with the constant-pressure heat capacity (in J/mol.K) given below. (Please write assumptions) ??(?) = 22.243 + 5.977 ∗ 10^-2∗ ? − 3.499 ∗ 10^-5∗ ?2 + 7.464 ∗ 10^-9∗ ?3arrow_forward

- Thermodynamic questionarrow_forwardAn adiabatic capillary tube is used in some refrigeration systems to drop the pressure of the refrigerant from the condenser level to the evaporator level. R-134a enters the capillary tube as a saturated liquid at 65.9 oC, and leaves at -12 oC. Determine the rate of entropy generation in the capillary tube for a mass flow rate of 0.83 kg/s. s1 (kJ/kgK) Format : 0.3382 x2 Format : 0.335 s2 (kJ/kgK) Format : 0.4832 Sgen (kW/K) Format : 0.0504arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY