Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:Refer to Appendix A for tables and equations to be used. Use the CNCI method.

water requirementinliters

w:c ratio

• Cement content (kg/m of concrete) =

• Mat = CBD (K – 0.1 FM)

You are given the following design parameters for a concrete mix:

M.

M.

D.

• Vols = 1000 -

The compressive strength of the concrete mix must be 40 MPa after 28 days. The cement

that is going to be used is a CEM I 52.5 with a relative density of 3.14. The stone available

Taps vis % water

30

is a 19.0 mm stone with a dry compacted bulk density (CBD) of 1780 kg/m3 and a relative

density of 2.24. An average, natural sand with a fineness modulus of 2.45 and a relative

25

20

density of 2.86 is going to be used for the mix. The slump on site is specified as 75 mm.

15

The concrete is going to be compacted by moderate vibration on site.

10

5

Calculate and show the amount of water, cement, stone and sand that is needed to make

10

15

20

Тарв

up 1 m3 of concrete mix as specified above.

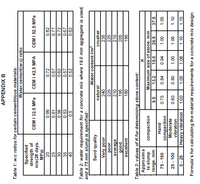

Transcribed Image Text:APPENDIX B

Table 1: w:c ratios for certain cementitious materials:

Water:cement(w:c) ratio

Specified

strength of

mix(28 days.

MPa)

CEM I 32.5 MPa

CEM I 42.5 MPA

CEM I 52.5 MPa

99'0

0.61

0.72

0.82

25

0.67

0.77

0.72

0.67

0.62

35

0.53

0.57

0.5

0.52

0.62

Table 2: water requirement for a concrete mix where 19.0 mm aggregate is used,

and a 75 mm slump is specified:

Water content I/m3

Sand quality

natural

crusher

Very poor

235

240

poor

225

225

average

210

215

205

poob

excellent

195

180

195

Table 3: values of K for determining stone content:

Approxima

te slump

K.

Maximum size of stone. mm

compaction

range. mm

9.5

13.2

19.0

26.5

37.5

Hand

75 - 150

0.75

0.84

0.94

1.05

compaction

Moderate

00'L

00'L

80'L

1.10

25 - 100

0.80

0.80

1.10

vibration

90'L

0 - 25

Heavy vibration

00'L

1.05

1.15

Formula's for calculating the material requirements for a concrete mix design:

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Note:hand written solution should be avoided.arrow_forwardOne cubic yard of fresh concrete mix includes 1900 lbs coarse and 1150 lbs fine aggregates. Water-cement ratio (W/C) for the mix is 0.5. Given information: Concrete weight = 150 pcf Weight of standard cement bags 94 lbs Water weight = 8.34 pounds per gallon Approximately how many bags of Portland cement should be added to each cubic yard of this mix? 4 bags 5 bags 6 bags 7 bagsarrow_forwardWorking on major construction project that requires considerable amounts of concrete to be used,you are asked to design a concrete mix following the BRE methodology. All the necessary tables forthis can be found in the Appendix. The concrete mix specifications are:o Characteristic compressive strength of 35 N/mm 2 at 28 days.o Failure rate of 2%o Previous control data yielded a standard deviation of 10 N/mm 2o CEM-I 42.5o Air-entraining is not requiredo Maximum water to cement ratio 0.40o Minimum cement content 390 kg/m 3o Required slump 50 mmo Coarse aggregate: Crushed maximum size 20mmo Fine aggregate: Uncrushed with 90% passing 600 μm sieveo Relative density of aggregates: 2.5o Coarse aggregate has 4% moistureo Fine aggregate is dry and has 1.2% absorption.o Volume of the required trial mix: 0.090 m 3Following the BRE step-by-step process estimate the water content of the mix estimate the content of aggregates, provide the estimated mix quantitiesarrow_forward

- I need answer within 20 minutes please please with my best wishesarrow_forwardWorking on major construction project that requires considerable amounts of concrete to be used,you are asked to design a concrete mix following the BRE methodology. The concrete mixspecifications are:o Characteristic compressive strength of 50 N/mm 2 at 7 days.o Failure rate of 2%o Previous control data yielded a standard deviation of 5 N/mm 2o CEM-I 52.5o Air-entraining is not requiredo Required slump 120 mmo Coarse aggregate: Crushed maximum size 10mmo Fine aggregate: Uncrushed with 45% passing 600 μm sieveo Relative density of aggregates: 2.7o Coarse aggregate has 4% moistureo Fine aggregate is dry and has 1.2% absorption.o Volume of the required trial mix: 0.120 m3 Create the mix design and state what actions and recommenations you would do if trial produced a result with a mean compressive strength of 64 MPa at 7 days and the slump was 80mm.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning