Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

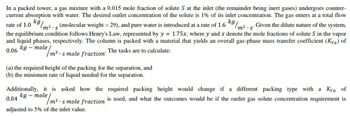

Transcribed Image Text:rate of 1.0 kg/

In a packed tower, a gas mixture with a 0.015 mole fraction of solute S at the inlet (the remainder being inert gases) undergoes counter-

current absorption with water. The desired outlet concentration of the solute is 1% of its inlet concentration. The gas enters at a total flow

/m²-s

Given the dilute nature of the system,

the equilibrium condition follows Henry's Law, represented by y = 1.75x, where y and x denote the mole fractions of solute S in the vapor

and liquid phases, respectively. The column is packed with a material that yields an overall gas-phase mass transfer coefficient (Kya) of

0.06 kg-mole

m³ smole fraction The tasks are to calculate:

kg

m2.s (molecular weight = 29), and pure water is introduced at a rate of 1.6

(a) the required height of the packing for the separation, and

(b) the minimum rate of liquid needed for the separation.

Additionally, it is asked how the required packing height would change if a different packing type with a Kya of

kg-mole

0.04

adjusted to 5% of the inlet value.

ole/m³..

m3. s mole fraction is used, and what the outcomes would be if the outlet gas solute concentration requirement is

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- 7-31. In the air dryer illustrated in Figure 7.31, part of the effluent air stream is to be recycled in an effort to control the inlet humidity. The solids entering the dryer (Stream #3) contain 20 % water on a mass basis and the mass flow rate of the wet solids entering the dryer is 1000 lb/h. The dried solids (stream 4) are to contain a maximum of 5 % water on a mass basis. The partial pressure of water vapor in the fresh air entering the system (Stream #1) is equivalent to 10 mm Hg and the partial pressure in the air leaving the dryer (Stream #5) must not exceed 200 mm Hg. In this particular problem the flow rate of the recycle stream (stream #6) is to be regulated so that the partial pressure of water vapor in the air entering the dryer is equivalent to 50 mm Hg. For this condition, calculate the total molar flow rate of fresh air entering the system (Stream #1) and the total molar flow rate of the recycle stream (Stream #6). Assume that the process operates at atmospheric pressure…arrow_forward4) For workers in closed spaces, it is a great danger to consuming the breathable air (oxygen) and replacing it with carbon dioxide (CO₂) is great danger issue. In order to avoid breathing this harmful gas, closed areas should be adequately ventilated. There is no specific standard for the air exchange rate. However, a complete freshening of air every 2.5 minutes has been accepted by the industry as effective ventilation. A worker maintains a rectangular tank with a height of 10 ft and a 5 ft x 5 ft square bottom. Fresh air enters through a 6-inch diameter hose and exits through a 3-inch diameter port on the tank wall. The flow is assumed to be incompressible and steady. Determine, a) The exchange rate required (ft³/min) for this tank. b) The velocity of the air entering and exiting the tank at this exchange rate.arrow_forwardGallium is produced by the electrolysis of a solution made by dissolving gallium oxide in concentrated NaOH(aq).Calculate the amount of Ga(s) that can be deposited from a Ga(III)solution using a current of 0.460 A that flows for 40.0 min. mass: garrow_forward

- A water droplet having a diameter of 0.10 mm is suspended in still air at 320K, 101 kPa, and 20% relative humidity. DAB = 0.220 cm2/s (a) Calculate the initial rate of evaporation of water (b) Determine the time for thewater droplet to evaporate completelyarrow_forwardThere is an unglazed porcelain disc with a thickness of 0.016 ft and a pore diameter of 7.874 x 10-6 in. Pure oxygen gas is passed through the pores at an initial absolute pressure of 2666.45 Pa at 212°F. Oxygen passes with a molar flux density of 0.093 cm3/cm2.s (at 2666.45 Pa and 212 °F). The oxygen pressure on the other side of the disk is estimated to be negligible. Determine the ton/min passing from gaseous Oxygen at 298 K and 10 mmHg abs.arrow_forwardTetrachloromethane at a concentration of 15 mg/L (C°)is to be reduced to 15 µg/L (C) by an air stripping tower. What is the required height (L) and the concentration of tetrachloromethane at the exit air (Ca) for the following conditions: (25p)Air to water flow ratio (Q/Q) = 40:1Q = 25 m³/h Cylindrical tower diameter (d) = 1 mHenry's constant (H) for tetrachloromethane = 0.98 Lw/LWater diffusion coefficient for chloroform (D) = 3x10 m²/sWater kinematic viscosity (vw) = 8.9x107 m²/sarrow_forward

- 4. [Scrubber]. A coal-fired combustion system produces flue gas that contains particulate matter. To reduce the amount of particles, the flue gas is treated in a scrubber. The measurement of the mass and size of the particles at the inlet and outlet of the scrubber yielded the size distribution data given in the following table: Particle diameter [um] (size interval: dlower → dupper) 0.10.25 0.25 → 0.5 0.5 → 1.0 1.0→2.0 2.05.0 Formulas for question 4: . Particle mass at scrubber inlet [mg] 623 55.4 12.6 8.9 7.1 5.0 10 7.7 10 →30 6.6 30→ 50 4.3 The mass of particles in each size interval was measured on a basis of 1 m²³. 31.4 33.2 123 a) What is the overall efficiency of the scrubber? [Ans: noverall 96.7 %] b) Calculate the collection efficiency (na,i) of the scrubber and the particle geometric average diameter (dpi) for each size interval. Create a graph showing the variation of na,i with dp,i. (PTO) efficiency: nd,i (%) = - 394 775 1055 c) Calculate the mass-average diameter of the…arrow_forwardWrite down the total and species (virus) mass balances for the air in the plane. Derive an equation for the concentration of virus particles in the air in the plane as a function of time.arrow_forwardQuestion 4: A well stirred storage vessel is originally filled with 500 kg of 20 wt % ethanol solution. The operator decided to dilute the solution in the vessel by flowing a 10 wt % ethanol solution at a rate of 1000 kg/h into the vessel and withdrawing the well stirred solution from the vessel at a rate of 500 kg/h. (a) Calculate the time it takes the solution in the vessel to reach a concentration of 15 wt % ethanol. (b) If the vessel can only hold 1500 kg of the solution, calculate the ethanol concentration when the vessel is completely filled. Assume that the density of ethanol solution during the operation remains essentially constant within the ethanol concentration range of operation.arrow_forward

- 10. A container is separated into two halves by a membrane. Your lab partner assistant, Thurmond, is supposed to place a MgCl2 solution on side 1 and a NaCl solution on side 2. He is then supposed to measure the rate of water movement across the membrane. Unfortunately, Thurmond is not very good about keeping complete lab notes and he has forgotten to write down some data and calculations. Using your knowledge of osmosis, complete the following table. Temperature is 15°C and the hydraulic conductivity for the membrane is 0.4 ml/atm sec. MgCl2 Concentration on Side 1 NaCl Concentration on Side 2 80 mM Osmolarity on Side 1 Osmolarity on Side 2 Difference in osmotic pressure 60 mosM across the membrane Jy 0.95 ml/sec Reflection coefficient (ơ) Direction of water movementarrow_forwardQ.1) In the experiment, you wrap a piece of copper wire around your magnesium strip to suspend the magnesium inside the eudiometer. Why is copper wire a good choice for this task? Group of answer choices It conducts electricity very well It reacts strongly with the acid It does not react with the acid It is much heavier than Mg Part B) A 45 mL sample of a dry gas is collected at 380 torr and 25 °C. Calculate the volume of the gas sample (in mL) at STP. Part C)Using the data provided in Table 3 in the handout (also provided below), calculate the vapor pressure of water at 21.0 °C. Table 3: Vapor pressure of water at various temperatures T (˚C) P (mmHg) T (˚C) P (mmHg) T (˚C) P (mmHg) 0 4.58 16 13.63 26 25.21 5 6.54 18 15.48 28 28.35 10 9.21 20 17.54 30 31.82 12 10.52 22 19.83 40 55.3 14 11.99 24 22.38 50 92.5arrow_forwardProblem 1. Air with 1.6 %mol SO₂ (you can assume very dilute conditions) is scrubbed with solute-free water in a packed column of 1.5 m² cross-sectional area and 3.5 m in height. The total gas flow rate is 0.062 kmol/s, the total liquid flow rate is 2.2 kmol/s, and the outlet air has an SO₂ mol fraction of 0.004. The equilibrium can be described by y*=40x. a) What is the minimum water flow rate required? b) How does the overall number of gas transfer units (NOG) compare to the number of theoretical stages required? c) What is the overall height of a gas transfer unit (HOG).arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The