Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

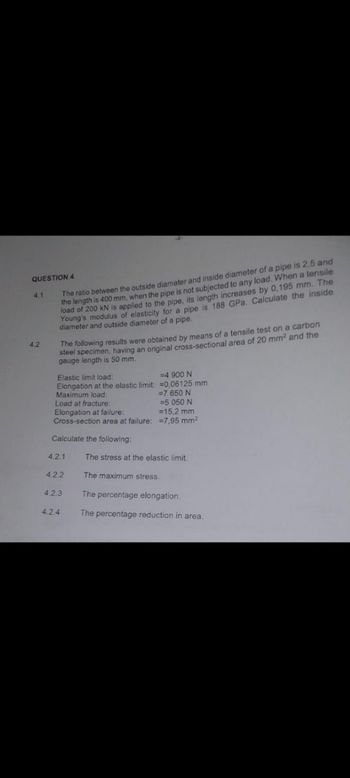

Transcribed Image Text:QUESTION 4

4.2

4.1

The ratio between the outside diameter and inside diameter of a pipe is 2,5 and

the length is 400 mm, when the pipe is not subjected to any load. When a tensile

load of 200 kN is applied to the pipe, its length increases by 0,195 mm. The

Young's modulus of elasticity for a pipe is 188 GPa. Calculate the inside

diameter and outside diameter of a pipe.

The following results were obtained by means of a tensile test on a carbon

steel specimen, having an original cross-sectional area of 20 mm² and the

gauge length is 50 mm.

Elastic limit load:

Elongation at the elastic limit: =0,06125 mm

=4 900 N

Maximum load:

=7 650 N

Load at fracture:

=5 050 N

Elongation at failure:

=15,2 mm

Cross-section area at failure:

7,95 mm²

Calculate the following:

4.2.1

The stress at the elastic limit.

4.2.2

The maximum stress.

4.2.3

The percentage elongation.

4.2.4

The percentage reduction in area.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- The error in a measurement due to strain when using a tape measure depends on the material that it is made of. For a tape with a cross section of 10 mm by 0.7 mm, calculate how much error is introduced in inches into the measurement at a 300 ft length if the tape is pulled with 80 N and if the tape is made of: a) mild steel (E = 30 x 10^6 psi), b) polycrystalline aluminum (E = 10 x 10^6 psi) c) fiberglass composite (E = 3.5 x 10^6 psi in the long direction)arrow_forwardsolve first one only and use b h and x to find the strainarrow_forward5. Consider a cylindrical specimen of a steel alloy (Figure 6.22) 10 mm in diameter and 75 mm long that is pulled in tension. Determine its elongation when a load of 20,000 N is applied. Stress (MPa) 600 500 400 300 200 100 0 0.00 0.04 Stress (MPa) 500 400 300 200 100 0.000 0.002 0.004 0.006 0.08 Strain Strain 0.12 0.16 0.20 Figure 6.22 Tensile stress-strain behavior for a steel alloy.arrow_forward

- b) A 1.25 m long cable has a diameter 3.50 mm with a Young's Modulus, E, of 9.75 x 10⁹ N/m². When the wire is placed under tension, it experiences a stress of 202.52 x 106 N/m², the length of the cable extends by 36.35 mm. Calculate the force that the cable experiences under tension and the strain energy density (U/V) due to deformation. Give your answers in newtons (N) to 2 decimal places for the force; and in joules per cubic metre (J/m³) for the strain energy density to 2 decimal places. Assume the cable is solid and the material is homogeneous. c) Figure Q1c shows a bracket on rollers that allow the bracket to move along a beam in the horizontal direction. A force F₁ of 2625 N acts at point A where the angle between F, and the x-axis is 100. If force F₂ acts at an angle a = 400 between F2 and the y-axis: (i) Determine the magnitude of F2 necessary to maintain bracket on horizontal equilibrium. (ii) Determine the vertical force at A acting along the y-axis. Give your answers to the…arrow_forwardWhen a bar of 22 mm diameter is subjected to an axial pull of 60 kN the extension on the 49 mm gauge length is 0.1 mm and there is a decrease in diameter of 0.013 mm. Calculate the Young's Modulus. Provide your answer in GN/m2 to the nearest whole number.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY