Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

Read the question carefully and Give me right solution according to the question

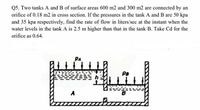

Transcribed Image Text:Q5. Two tanks A and B of surface areas 600 m2 and 300 m2 are connected by an

orifice of 0.18 m2 in cross section. If the pressures in the tank A and B are 50 kpa

and 35 kpa respectively, find the rate of flow in liters/sec at the instant when the

water levels in the tank A is 2.5 m higher than that in the tank B. Take Cd for the

orifice as 0.64.

Pa

A

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The answer is one of the options below please solve carefully and circle the correct option Please write clear .arrow_forwardWhen you substitute AD in step 5, why do you get rid of the negative? In step 4 you keep it negative when finding CD.arrow_forwardA dust particle is suspended in the air (floating due to a small updraft and its own low mass) when a powerful loudspeaker plays a very low note (2 Hz so it can’t be heard but you can actually see the speaker move!). How will the dust particle move as a result of the speaker being turned on? Question 3 options: A) The dust particle will move up and down. B) The dust particle will be pushed across the room. C) The dust particle will move in a circular path. D) The dust particle will move side to side.arrow_forward

- Don’t use aiarrow_forwardCase Study Determine Properties from Tensile Test Data A cylindrical specimen of stainless steel having an initial diameter of 12.8mm and initial length of 50.8mm is pulled in tension. Use the data provided below to a) Plot the data as engineering stress versus engineering strain using excel or similar software. b) Compute the modulus of elasticity. c) Determine the yield strength at a strain offset of 0.002. d) Determine the tensile strength of this alloy. e) What is the approximate ductility, in percent elongation? f) Compute the modulus of resilience. Load (N) Length (mm) 50.800 12,700 25,400 38,100 50,800 76,200 50.825 50.851 50.876 50.902 50.952 89,100 92,700 51.003 51.054 102,500 107,800 119,400 128,300 149,700 159,000 160,400 159,500 151,500 124,700 51.181 51.308 51.562 51.816 52.832 53.848 54.356 54.864 55.880 56.642 Fracturearrow_forwardQuestion 4 How do you start a measuring plan to align the following part? What is alignment? What is the difference between features and characteristics? How do you measure cylinders C1 or C2? How do you measure Plane A? How do you measure the distance between C1 and C3? L2 C1 C4 L4 L1 C3 C2 B.arrow_forward

- Handwriting not allow please And give me complete answerarrow_forwardASK Question Four The following data were recorded during the tensile test of a 14-mm diameter mild steel rod. The gage length was 50 mm. at fracture, the elongation between the gage marks was 4.0 mm and the minimum diameter was 11.3 mm a) Plot the conventional stress-strain curve for the mild steel b) determine the proportional limit c) Modulus of elasticity d) Yield stress at 0.2% c) Ultimate stress f) Breaking strength g) Percent elongation in 50 mm and reduction in area Load (N) 0 Elongation (mm) 0 6310 0.01 12600 0.02 18800 0.03 25100 0.04 31300 0.05 37900 0.06 40100 0.163 41600 0.433 46200 1.25 $2400 2.5 58500 4.5 68000 75 2arrow_forwardRound off the following number to three significant figures:68.534sarrow_forward

- 71.7 is being marked wrong in McGraw Hill homework. I thought I had done it right with putting 86.03 but that is wrong also. I'm not trying to just find the answer, trying to find how to do this. Could there be a different number than 71.7? Where does the μk=0.20 come into the equation?arrow_forwardHi, Could you please help with this question, if you need to take more credits then please feel free. showing working out if possible too please, Thank youarrow_forwardQuestion 2 You are a biomedical engineer working for a small orthopaedic firm that fabricates rectangular shaped fracture fixation plates from titanium alloy (model = "Ti Fix-It") materials. A recent clinical report documents some problems with the plates implanted into fractured limbs. Specifically, some plates have become permanently bent while patients are in rehab and doing partial weight bearing activities. Your boss asks you to review the technical report that was generated by the previous test engineer (whose job you now have!) and used to verify the design. The brief report states the following... "Ti Fix-It plates were manufactured from Ti-6Al-4V (grade 5) and machined into solid 150 mm long beams with a 4 mm thick and 15 mm wide cross section. Each Ti Fix-It plate was loaded in equilibrium in a 4-point bending test (set-up configuration is provided in drawing below), with an applied load of 1000N. The maximum stress in this set-up was less than the yield stress for the…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY