Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

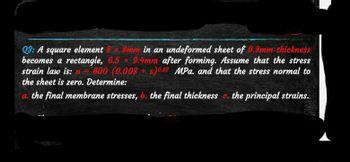

Transcribed Image Text:Q3: A square element 8x8mm in an undeformed sheet of 0.8mm thickness

becomes a rectangle, 6.5 x 9.4mm after forming. Assume that the stress

strain law is: 600 (0.008+)0.22 MPa. and that the stress normal to

the sheet is zero. Determine:

a. the final membrane stresses, b. the final thickness c. the principal strains.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 6 steps with 6 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- M13.6 Principal stresses from rosette data scenes -200 µE 23 Eb = 200 με Ec 500 µE 30° 30° Ex (LE) a Ey (µE) Yxy (Lurad) The strain rosette shown was used to obtain normal strain data at a point on the free surface of a steel (E = 200 GPa; v = 0.32) plate. Op1 (MPa) Determine the normal strains, the shear strain, and the principal stresses in the x-y plane. Op2 (MPa) Try One 1st 2nd 3rd attempt enterarrow_forwardFigure 2.1. shows two long plates with same material and equal width w=20 mm that are subjected to a uniaxial tensile load o. One of the plates has a single small central hole with diameter 4mm and another plate has two small holes with a distance of 8mm from each other. The holes are perpendicular to the external tensile load. Develop a computer code (or simulation model) and analyze how stresses will be distributed at the tip of the holes in these two plates for different values of 0. 4mm Figure 2.1. 8mm 4mmarrow_forward20 (B) An air vessel, which is made of steel in 2 m long. It has an external diameter 44 cm and is 2 cm thick. 1. Calculate the permissible pressure difference allowed between the inside and outside if the longitudinal stress in the wall must not exceed 20 MPa. 2. Determine longitudinal and hoop strains. 3. Calculate the change in diameter and change in volume. Take E = 200 GPa and v = 0.3arrow_forward

- Help me understand by teaching me the solution. Thanks i upvote.arrow_forwardIf the engineering strain in a tensile bar is 0.0025 and Poisson’s ratio is 0.33, find the original length and the original diameter if the length and diameter under load are 2.333 ft. and 1.005 in. respectively.arrow_forward5. Consider a cylindrical specimen of a steel alloy (Figure 6.22) 10 mm in diameter and 75 mm long that is pulled in tension. Determine its elongation when a load of 20,000 N is applied. Stress (MPa) 600 500 400 300 200 100 0 0.00 0.04 Stress (MPa) 500 400 300 200 100 0.000 0.002 0.004 0.006 0.08 Strain Strain 0.12 0.16 0.20 Figure 6.22 Tensile stress-strain behavior for a steel alloy.arrow_forward

- A metal bar of 0.5 meters diameter and a meter long is compressed in length by a force of 850KN. 1. For both the longitudinal and diametrical directions calculate the stress and the strain. 2. Change in diameter and length. 3. With a poisons ratio of 0.3 and modulus of elasticity of 185GPa calculate the bulk modulus 4. Using the relation between the bulk modulus and Young’s modulus find the modulus of rigidity.arrow_forwardIn the attached picture there is a sketch of a socket wrench. Assume the wrench is held at a fixed point “A”. The yield stress of the material is known to be 500 MPa. Answer the questions below Describe the stresses at point “A” and their causes and calculate the stresses. Determine the factor of safety against yield assuming the Tresca yield criteria. Determine the factor of safety against yield assuming the von Mises yield criteria using both principal stresses and “Cartesian” stresses. Do your values match or not, and is this expected? Explain. Do the calculated values make sense with the respect to the Tresca value? Explain, why or why not?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY