Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

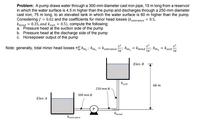

Transcribed Image Text:Problem: A pump draws water through a 300-mm diameter cast iron pipe, 15 m long from a reservoir

in which the water surface is 4.5 m higher than the pump and discharges through a 250-mm diameter

cast iron, 75 m long, to an elevated tank in which the water surface is 60 m higher than the pump.

Considering f = 0.02 and the coefficients for minor head losses (kentrance = 0.5,

kpend = 0.35, and kexit = 0.5), compute the following:

a. Pressure head at the suction side of the pump

b. Pressure head at the discharge side of the pump

c. Horsepower output of the pump

Note: generally, total minor head losses =E h,m, ; hm, = kentrance

; hm, = kpend :

2g

hm, = kexit

2g

29

Elev.B

kexit

60 m

250 тm Ф

300 тm Ф

Elev. A

kpend

kentrance

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Problem modified from Example 5.8. The 20-cm-diameter (= d) tank of Figure 5.15 shown in the textbook contains chloroform, and it is being drained by the attached piping system. The pipe Section itself is made of 3-nominal schedule 40 commercial steel and it is 25 m long. Considering minor losses (90° elbow, regular), determine the variation of velocity and height with time if the height h is allowed to vary from an initial value of 2 m to 1.2 m. Assuming that the constant friction factor formulation can be applied. h d - D FIGURE 5.15. The unsteady draining tank problem.arrow_forward0105 Water at 40 °C is pumped from an open tank through 200 m of 50-mm-diameter smooth horizontal pipe as shown in Figure 1 and discharges into the atmosphere with a velocity of 3 m/s. Minor losses are negligible. (a) If the efficiency of the pump is 70%, how much power is being supplied to the pump? (b) What is the NPSHA at the pump inlet? Neglect losses in the short section of pipe connecting the pump to the tank. Assume standard atmospheric pressure. Note: for smooth pipe, friction factor, f = 0.0152 and at 40 °C. kinematic viscosity Temperature (°C) Water vapor pressure (N/m²) Specific weight (N/m³) (m²/s) 6.58 x 10-7 40 7.376 x 10³ 9.731 x 10³ T 3 m ! PUMP 9.731* Diameter = 50 mm Length 200 m e Figure 1arrow_forwardI need help on this question: According to the question: a) If the pipe connected to the pump inlet has a diameter of 24 mm with length (LCP) of 5 m and Darcy friction factor of 0.03, what would be the actual head rise across the pump for a case where the pump outlet pressure is 200 kPa? The difference in height between pump inlet and outlet is 0.25 m, the tank exit is sharp-edged, and the water level in the tank to the tank exit pipe (HWL) is 2 m. Also, consider that the flow velocity inside the tank is negligible. The value of the actual head rise across the pump is = ? b) What would be the pump motor power if the efficiency is 60%? The value of the pump motor power is = ?arrow_forward

- Ex ....... HYDRAUE • The pump is to be connected to a rising main which has a diameter (D) of 400 mm and a length of 137 m.The entry exit and minor head losses in the pipeline can be taken as 80D in this particular situation. The friction loss can be approximated by h; = ALQ² / 1 2D5 with A=0.04. The static lift is 10 m. By considering a single pump (P). And two of the pumps in series (P+P) and parallel (P//P) determine: > the H-Q curve of the two pump combinations » Which combination will be capable of discharging at least 0.3 m³/s, with the ability to pump up to 0.35 m³/s if the need arises. %3Darrow_forwardIn a 225 mm pipeline 0.14 m3/s of water are pumped from a reservoir of surface elevation30 over a hill of elevation 50. A pump of what power is required to maintain a pressure of 345kPa on the hilltop if the head lost between reservoir and hilltop is 6 m?arrow_forwardPROBLEM 3 Water, p = 1000 kg/m³ and μ = 0.001 kg/m.s, is pumped between two reservoirs at 5 liter/s through 125 m of 5 cm-diameter pipe and several minor losses, as shown in Fig. The roughness ratio is e/d= 0.001. Compute the pump horsepower required. 2₂= 40m Screwed regular 90° elbow Sharp exit Ģ2 1 2₁ = 7m GI Sharp entrance Half-open gate valve Open globe valve 30 cm bend radius 125m of pipe, d= 5 cm Pumparrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY