Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

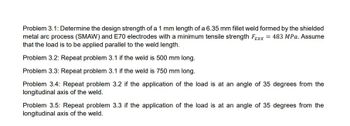

Transcribed Image Text:Problem 3.1: Determine the design strength of a 1 mm length of a 6.35 mm fillet weld formed by the shielded

metal arc process (SMAW) and E70 electrodes with a minimum tensile strength Fexx = 483 MPa. Assume

that the load is to be applied parallel to the weld length.

Problem 3.2: Repeat problem 3.1 if the weld is 500 mm long.

Problem 3.3: Repeat problem 3.1 if the weld is 750 mm long.

Problem 3.4: Repeat problem 3.2 if the application of the load is at an angle of 35 degrees from the

longitudinal axis of the weld.

Problem 3.5: Repeat problem 3.3 if the application of the load is at an angle of 35 degrees from the

longitudinal axis of the weld.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step 1: Define the given data and what is to find

VIEW Step 2: 3.1 Determine the design strength:

VIEW Step 3: 3.2 Determine the design strength:

VIEW Step 4: 3.3 Determine the design strength:

VIEW Step 5: 3.4 Determine the design strength:

VIEW Step 6: 3.5 Determine the design strength:

VIEW Solution

VIEW Step by stepSolved in 7 steps with 7 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- the is allowable because member metal is incorporated into the welds? (Ams/11.3 kip) (4) A 5/16 -in steel bar is welded to a vertical support as shown in the figure. What is the shear stress in the throat of the welds if the force F is 32 kip? (Ans/181 kip) 2 in 2 inarrow_forwardSolve this problem with diagramarrow_forwardi need the answer quicklyarrow_forward

- 02: Two plates, 20 mm thick, are welded together by means of transverse-fillet welds. The ultimate tensile strength of a weld metal is 415 MPa. The surface finish factor of the weld surface is 0.5, and the size factor is 0.85. The reliability is 90%. Determine the length of the weld if the factor of safety is 2.5. The transverse force on the welds is 80 kN, which is completely reversed under fatigue loading. Take: A=13mm. 25 A, Toe Good luckarrow_forwardA corner fillet weld with cross sectional area of 75 mm is made using oxyacetylene welding. Material of the welded plates is low carbon steel (Um = 10.3 J/mm'. Travel speed at which the bead is formed = 5 mm/s. Assume that only 40% of the energy generated by the torch is used for melting the metal; the rest is dissipated. If heat of combustion for acetylene is= 54.8 MJ/m³ , determine the volume flow rate of acetylene required to perform this OAW operation.arrow_forwardNeed help typingarrow_forward

- (2) h Q11 what the value of P Which are safer on the rivets as shown in figure below. given that : T=100.34 MPa, ob=370.3 MPa, 19mm diameter of .rivets 12.5m 19mm 12.5m 250mm P.arrow_forwardTe - Effective throat thickness well in mm = 6 sin45° Consider the following drawing in which plate 1 is welded onto plate 2 as shown for tensile and shear loading. The plates are fillet welded with a weld thickness of 6 mm as shown for a length of 150 mm. The plates have an ultimate strength of 275 MPa and the welding was done with F70 welding electrodes, which possesses an ultimate strength of 483 MPa. Consider a partial factor of safety of 1.7 for the welded joint and determine the design strength of the weld joint, both in tension (Tdw) and in shear (Vdw) due to the forces acting on it. a) Determine the design strength of the following weld in tension ( ) due to vertical forces. b) Determine the design strength of the weld in shear ( ) due to horizontal forces. Attached pic is shear equation for calculation Tension equation for calculation is: Tdw = FyLwte /Ymwarrow_forward11.16 Two 20-mm steel plates are butt-welded together. Both the plate and the welding electrode materials correspond to strength properties of Su = 500 MPa and S, = 400 MPa. The imposed loading fluctuates rapidly between -20 and +60 kN. Estimate the length of weld required in order to provide a safety factor of 2.5: (a) If the weld reinforcement is not removed. (b) If the excess weld material is carefully ground off to provide smooth, continu- ous surfaces.arrow_forward

- Please solve step by step , Don't use any Aiarrow_forward2. A G10200 HR steel bar of thickness h is welded to a vertical support of the same material as shown below. If an E6010 electrode is used, determine the maximum force F that can be applied while satisfying welding code. The dimensions are h=5 mm, b = 50 mm, and d = 50 mm. HINT: you will need to check failure of the weld material and base materials. d b h Farrow_forwardAn angle iron made of AISI 1040 CD steel is welded to metal as shown and loaded with a dynamic load varying between +40kN and +60kN. E70XX (Sut = 482MPa, Sy = 393MPa) will be used as the welding electrode. Find the factor of safety of the weld zone. Note: that both static and dynamic loads are applied to the source.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY