Steel Design (Activate Learning with these NEW titles from Engineering!)

6th Edition

ISBN: 9781337094740

Author: Segui, William T.

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

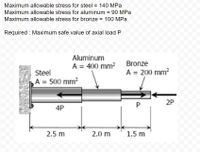

Maximum allowable stress for steel = 140 MPa

Maximum allowable stress for aluminum = 90 MPa

Maximum allowable stress for bronze = 100 MPa

Required : Maximum safe value of axial load P

Transcribed Image Text:Maximum allowable stress for steel = 140 MPa

Maximum allowable stress for aluminum = 90 MPa

Maximum allowable stress for bronze = 100 MPa

Required : Maximum safe value of axial load P

Aluminum

A = 400 mm² Bronze

Steel

A = 200 mm?

A = 500 mm?

2P

4P

2.5 m

2.0 m

1.5 m

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- A tensile test was performed on a metal specimen with a diameter of 1 2 inch and a gage length (the length over which the elongation is measured) of 4 inches. The dam were plotted on a load-displacement graph. P vs. L. A best-fit line was drawn through the points, and the slope of the straight-line portion was calculated to be P/L =1392 kips/in. What is the modulus of elasticity?arrow_forwardA tensile test was performed on a metal specimen having a circular cross section with a diameter 0. 510 inch. For each increment of load applied, the strain was directly determined by means of a strain gage attached to the specimen. The results are, shown in Table: 1.5.1. a. Prepare a table of stress and strain. b. Plot these data to obtain a stress-strain curve. Do not connect the data points; draw a best-fit straight line through them. c. Determine the modulus of elasticity as the slope of the best-fit line.arrow_forwardCompare the engineering and true secant elastic moduli for the natural rubber in Example Problem 6.2 at an engineering strain of 6.0. Assume that the deformation is all elastic.arrow_forward

- The results of a tensile test are shown in Table 1.5.2. The test was performed on a metal specimen with a circular cross section. The diameter was 3 8 inch and the gage length (The length over which the elongation is measured) was 2 inches. a. Use the data in Table 1.5.2 to produce a table of stress and strain values. b. Plot the stress-strain data and draw a best-fit curve. c. Compute the, modulus of elasticity from the initial slope of the curve. d. Estimate the yield stress.arrow_forwardA tensile test was performed on a metal specimen having a circular cross section with a diameter of 1 2 inch. The gage length (the length over which the elongation is measured) is 2 inches. For a load 13.5 kips, the elongation was 4.6610 3 inches. If the load is assumed to be within the linear elastic rang: of the material, determine the modulus of elasticity.arrow_forwardusing Figure 5-27, what is the advantage of the suspended type magnet over the other two types of magnets?arrow_forward

- Estimate the transverse tensile strength of the concrete in Problem 12.6.arrow_forwardAccording to Figure 5-20, is ii possible to completely separate one of the four materials from the other three? Explain your answer.arrow_forwardCompute the nominal shear strength of an M107.5 of A572 Grad 65 steel.arrow_forward

- How does a tensile stress differ from a compressive stress?arrow_forwardThe frame of a space shuttle type vehicle must have a high yield strength and high stillness, and the most important design factor is weight. Of all the materials presented in this chapter, what material might be the most suitable for the frame of a space shuttle? Assume that there will be both tensile and compressive stresses. For a space shuttle, cost is not a limiting factor. (a) You can eliminate entire classes of materials from consideration with a brief statement about their unsuitability. (b) What material has the highest specific yield strength? Give the yield strength, specific gravity, specific yield strength, elastic modulus, and specific elastic modulus for this material. (c) What material has the highest specific elastic modulus? Give the yield strength, specific gravity, specific yield strength, elastic modulus, and specific elastic modulus for this material. (d) Compare the materials with the highest specific yield strength and highest specific elastic modulus for suitability in the space shuttle frame. (C) Discuss the suitability of the top-rated material for this design from the viewpoint of the ability to produce a frame.arrow_forwardIn concrete work, Fuller and Thompson (1907) suggested that a dense packing of grains can be achieved if the percent finer (p) and grain size (D) are related by the following equation, where n is a constant varying in the range of 0.3-0.6. Dmax is the size of the largest grain within the soil. p=(DDmax)n100 This equation is sometimes used in roadwork for selecting the aggregates. a. For n = 0.5, show that the soil is well graded. b. If n = 0.5 and Dmax = 19.0 mm, find the percentages of gravel, sand, and fines within the soil. Use the Unified Soil Classification System.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning, Engineering Fundamentals: An Introduction to Engi...Civil EngineeringISBN:9781305084766Author:Saeed MoaveniPublisher:Cengage Learning

Engineering Fundamentals: An Introduction to Engi...Civil EngineeringISBN:9781305084766Author:Saeed MoaveniPublisher:Cengage Learning Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning

Solid Waste Engineering

Civil Engineering

ISBN:9781305635203

Author:Worrell, William A.

Publisher:Cengage Learning,

Engineering Fundamentals: An Introduction to Engi...

Civil Engineering

ISBN:9781305084766

Author:Saeed Moaveni

Publisher:Cengage Learning

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning